Color Specification, Quality Control, and Verification

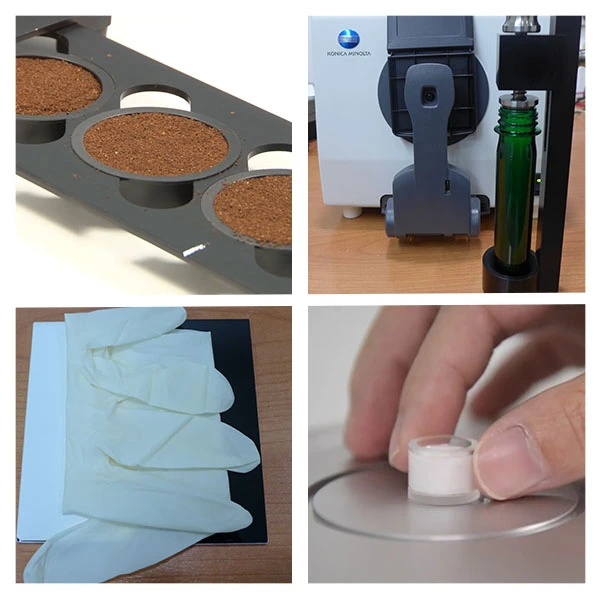

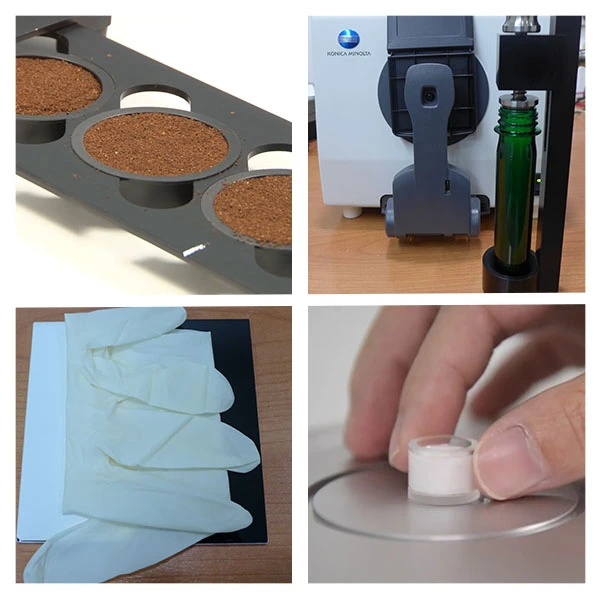

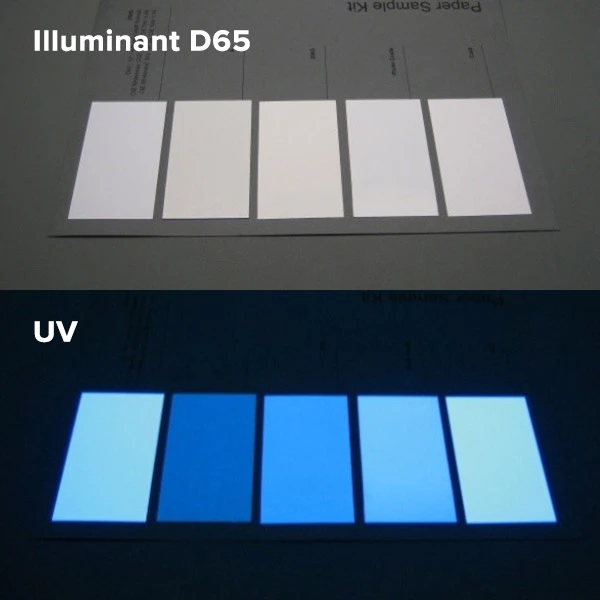

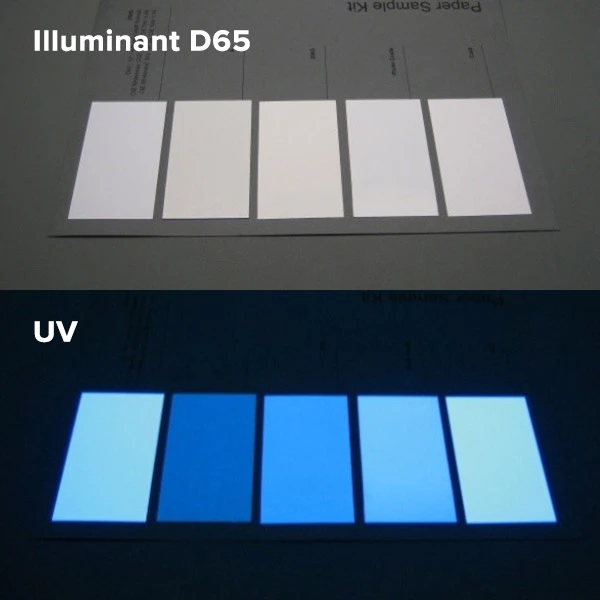

High-quality textile manufacturing begins with consistent raw materials. Variations in fibers, yarns, dyes, or chemicals can lead to downstream color shifts, rework, and product rejection. Objective color measurement helps ensure stable incoming quality and reliable formulation control. The spectrophotometer CM-3700A Plus is ideal for laboratory or central QC use, helping establish and maintain consistent color standards for raw materials and reference samples across sites and suppliers. The Spectrophotometer CM-36dG is well-suited for routine laboratory quality control, combining spectrophotometric color measurement with Numerical UV Control for evaluating materials containing optical brighteners. For daily incoming inspection and general QC, the Spectrophotometer CM-5 offers practical, stand-alone operation and flexible measurement of various raw material forms, from loose fibers and yarn bundles to powders and liquid dyes. It supports both reflectance and transmittance measurement, with a wide range of accessories to support typical textile laboratory workflows.

Recommended Products:

Spectrophotometer CM-3700A Plus

Spectrophotometer CM-36dG

Spectrophotometer CM-5

Related Links:

Color Control and Verification

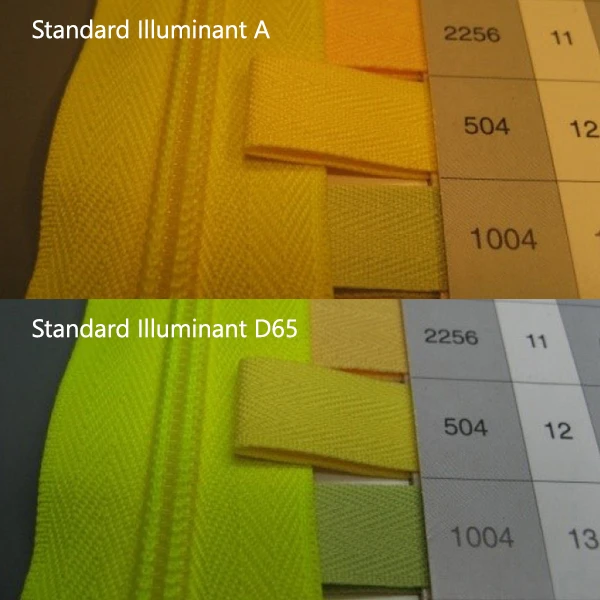

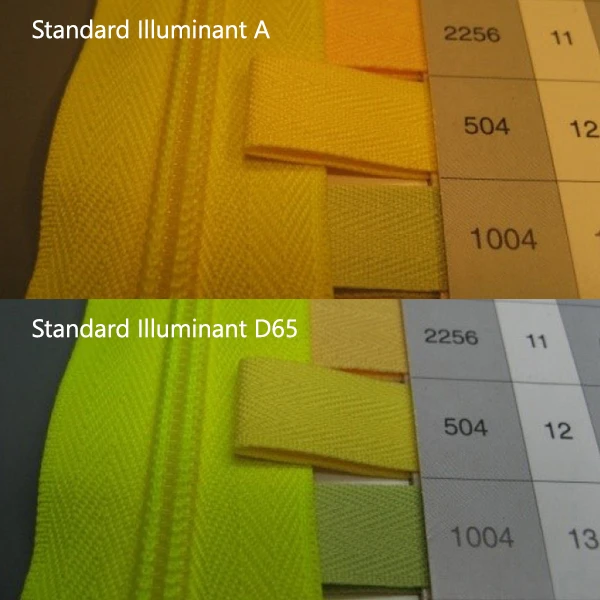

Consistent color control during dyeing and printing is critical to achieving target shades and maintaining batch-to-batch consistency. Variations in process conditions, substrates, or formulations can result in visible color deviations that are difficult to correct downstream. Objective color measurement enables reliable process control and early detection of deviations. The Spectrophotometer CM-36dGV is well-suited for laboratory and at-line quality control of dyed and printed textiles, providing accurate spectrophotometric color measurement with Numerical UV Control for evaluating materials containing optical brighteners. For production-floor verification, the Spectrophotometer CM-26d enables convenient portable measurement. It supports 100% UV / 0% UV measurement, allowing practical evaluation of fluorescence effects from optical brighteners and helping maintain consistency between laboratory and production decisions while reducing re-dyeing, rework, and material waste.

Recommended Products:

Related Links:

Color Control and Verification

The textile structure (weave or knit) can affect the final color and visual appearance. Downstream processes such as finishing, garment washing, heat-setting, and handling can also cause visible shade changes. Objective color measurement provides a consistent reference for evaluating these variations, enabling reliable decision-making across fabric types, production batches, and inspection locations while meeting brand and customer color specifications.

The Spectrophotometer CM-36dGV supports detailed laboratory evaluation of fabrics and finished products by delivering stable and repeatable spectrophotometric color measurement with Numerical UV Control, enabling accurate assessment of materials containing optical brighteners. With four selectable measurement apertures (Ø 4.0, 8.0, 16.0, and 25.4 mm), it allows appropriate measurement configurations for a wide range of textile textures and sample sizes, supporting robust quality control and verification. For final inspection and shipment approval, the portable Spectrophotometer CM-26d enables fast, on-site color verification of finished garments and textile products. Its 100% UV/0% UV adjustment capability supports practical evaluation of fluorescence effects from optical brighteners, where relevant, helping maintain consistency between laboratory assessments and final inspection decisions.

Recommended Products:

Related Links:

Color Quality Control and Verification

High-visibility clothing requires strict control of color performance to ensure consistent visibility and compliance with international safety standards such as EN ISO 20471. Because visual assessment alone cannot reliably evaluate high-visibility colors, objective instrumental measurement is essential. To meet the measurement geometry defined by EN ISO 20471, high-visibility clothing is evaluated using 45°:0° geometry. The Spectrophotometer CM-25cG is specifically designed for this application, providing accurate and repeatable color measurement for high-visibility fabrics and garments. Its portable design supports efficient color control and verification during production and final inspection, helping manufacturers ensure compliance and consistent safety performance.

Recommended Products:

Related Links: