Penggolongan Tomat yang Efisien dengan Spektrofotometer

Kualitas tomat memainkan peran penting dalam kepuasan konsumen dan daya saing pasar. Baik tomat yang ditujukan untuk rak ritel maupun pengolahan industri, tomat harus memenuhi standar ketat untuk kematangan, keseragaman dan daya tarik visual. Di antara kriteria ini, warna adalah salah satu indikator terpenting dari kematangan dan kualitas. Warna memengaruhi persepsi konsumen, keputusan pembeli dan hasil pengolahan hilir, terutama dalam aplikasi di mana warna yang konsisten sangat penting.

Selama beberapa dekade, penilaian kualitas tomat sangat bergantung pada inspeksi visual. Meskipun inspektur yang terampil dapat mengidentifikasi perbedaan tingkat kematangan yang luas, evaluasi manual menimbulkan variabilitas yang tak terhindarkan. Kondisi pencahayaan, kelelahan dan persepsi individu semuanya dapat memengaruhi hasilnya, menciptakan inkonsistensi yang berdampak pada akurasi penilaian. Seiring meningkatnya volume produksi dan ekspektasi kualitas, produsen tomat membutuhkan metode evaluasi yang lebih cepat dan lebih andal. Spektrofotometer untuk mengatasi kebutuhan ini, kami menyediakan pengukuran warna yang objektif dan dapat diulang, sehingga menghilangkan unsur subjektivitas dari proses penilaian warna.

Pentingnya Pengukuran Warna yang Akurat dalam Penilaian Tomat

Warna adalah salah satu indikator kematangan tomat yang paling jelas. Transisi dari hijau ke merah mencerminkan perubahan biokimia alami yang memengaruhi rasa, tekstur dan kesesuaian untuk berbagai pasar. Konsumen pasar segar mengharapkan warna yang cerah dan seragam, sementara fasilitas pengolahan seringkali membutuhkan rentang warna tertentu untuk memenuhi spesifikasi produk.

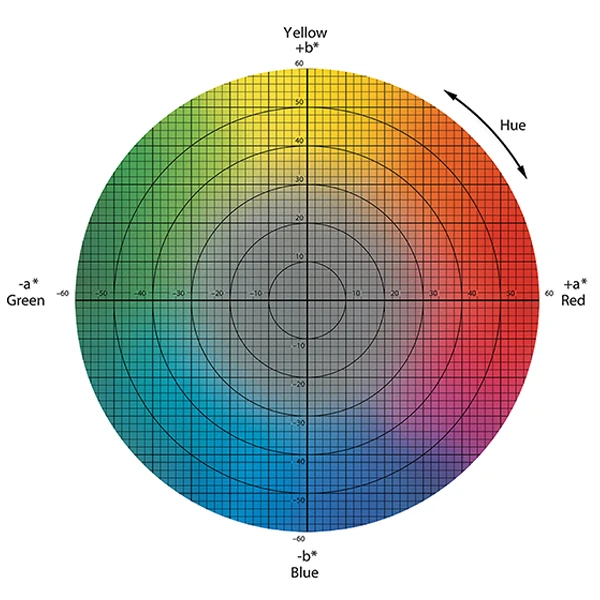

Namun, perbedaan warna yang halus sulit dinilai secara konsisten dengan mata manusia. Spektrofotometer mengatasi tantangan ini dengan mengukur warna menggunakan sistem warna yang diakui secara internasional seperti Ruang warna CIE L*a*b* . Setiap pengukuran menghasilkan nilai numerik yang tepat yang dapat dibandingkan langsung dengan standar yang telah ditentukan. Hal ini menghilangkan kesalahan interpretasi, mengurangi kesalahan klasifikasi, dan memastikan bahwa kriteria penilaian yang sama diterapkan di setiap batch.

Pengukuran warna secara objektif juga mendukung ketertelusuran yang lebih baik. Produsen dapat menyimpan dan meninjau data pengukuran, membuat dokumentasi yang memperkuat transparansi dan membantu menjaga konsistensi kualitas produk di seluruh rantai pasokan. Rantai pasokan seiring dengan pergeseran industri menuju kontrol kualitas berbasis data, kemampuan ini menjadi semakin berharga.

Bagaimana Spektrofotometer Meningkatkan Alur Kerja Sortir Tomat

Spektrofotometer mengukur cahaya yang dipantulkan dari permukaan tomat dan mengubahnya menjadi informasi warna yang akurat dalam hitungan detik. Alat ini memungkinkan inspeksi cepat tanpa bergantung pada bagan visual atau penilaian subjektif. Kemampuan untuk menangkap data yang konsisten dan berpresisi tinggi sangat meningkatkan efisiensi alur kerja dalam panen, penyortiran dan kontrol kualitas akhir.

Ketika semua petani dan pengemas yang memasok pembeli menggunakan standar warna dan jenis instrumen yang sama, penilaian mutu menjadi jauh lebih konsisten di berbagai lokasi. Ambang batas numerik yang jelas mengurangi perbedaan, meningkatkan komunikasi dengan pembeli, dan membantu memastikan bahwa tomat memenuhi harapan saat tiba.

Selain mendapatkan nilai L*a*b* mentah, banyak operasi mendapat manfaat dari metrik penilaian yang disederhanakan. Perangkat lunak analisis warna modern memungkinkan pengguna untuk membuat rumus penilaian khusus, yang dikenal sebagai indeks yang ditentukan pengguna, menggabungkan beberapa parameter warna menjadi satu skor yang mudah diinterpretasikan. Skor ini dapat disesuaikan untuk mewakili kematangan, tingkat kualitas atau persyaratan pelanggan tertentu. Kelompok tomat kemudian dapat ditetapkan ke kelas yang telah ditentukan berdasarkan hasil indeks ini, memungkinkan penilaian yang cepat dan seragam tanpa perlu interpretasi manual.

Solusi Pengukuran Warna Konica Minolta Sensing untuk Peng gradingan Tomat

Konica Minolta Sensing menawarkan berbagai macam instrumen pengukuran warna yang dirancang untuk memenuhi tuntutan pengendalian mutu pertanian modern. Spektrofotometer CM-26dG adalah salah satu solusi untuk penilaian tomat karena kemampuannya memberikan pengukuran warna yang sangat akurat dan mengukur kilap permukaan dalam satu kali pembacaan. Data kilap memberikan wawasan berharga tentang penampilan permukaan, menawarkan evaluasi kualitas visual yang lebih lengkap dan mendukung keputusan penilaian yang lebih tepat.

Saat dipasangkan dengan perangkat lunak data warna SpectraMagic™ NX2 CM-26dG memungkinkan pengguna untuk membuat indeks penilaian khusus, menentukan ambang batas klasifikasi, menganalisis tren, dan menghasilkan laporan yang mendukung manajemen kualitas yang konsisten dan berbasis data.

Simaklah whitepaper ini tentang Pengaturan Indeks Pengguna untuk Pengelompokan Tomat yang Efisien Menggunakan CM-26dG. Untuk detail lebih lanjut tentang cara mengatur Indeks Pengguna dan Kelas Pengguna untuk mendukung penilaian tomat yang lebih cepat dan konsisten.

Selain CM-26dG, Konica Minolta Sensing juga menawarkan berbagai instrumen pengukuran warna yang presisi dan andal untuk memenuhi berbagai kebutuhan pengeditan warna dan skala operasional. Solusi pengukuran warna seperti Spektrofotometer seri CM-17d, Chroma Meter seri CR-400, dan Spektrofotometer CM-5 menyediakan pilihan serbaguna untuk mengukur warna tomat di lingkungan laboratorium, jalur produksi dan lapangan. Bersama-sama, instrumen-instrumen ini menawarkan fleksibilitas kepada produsen untuk memilih kombinasi alat yang ideal guna mendukung proses penilaian dan persyaratan pengendalian mutu mereka yang unik.

Dari kiri ke kanan: Spektrofotometer CM-26dG, Spektrofotometer CM-17d, Chroma Meter CR-400, and Spektrofotometer CM-5.

Siap meningkatkan efisiensi proses sortir tomat Anda? Hubungi pakar kami untuk mempelajari lebih lanjut tentang solusi pengukuran warna kami atau untuk menjadwalkan konsultasi atau demonstrasi gratis.