-

The Standard in Measuring Color & Light

The Standard in Measuring Color & Light

-

The Standard in Measuring Color & Light

The Standard in Measuring Color & Light

-

The Standard in Measuring Color & Light

The Standard in Measuring Color & Light

-

The Standard in Measuring Color & Light

The Standard in Measuring Color & Light

-

The Standard in Measuring Color & Light

The Standard in Measuring Color & Light

-

The Standard in Measuring Color & Light

The Standard in Measuring Color & Light

-

The Standard in Measuring Color & Light

The Standard in Measuring Color & Light

-

The Standard in Measuring Color & Light

The Standard in Measuring Color & Light

Properties such as length and weight are easy to measure with a ruler or scale because the physical quantities are absolute. Measuring color is different. Color is a perceived phenomenon, reliant on our brain as well as the object itself and the light source shining on it. Because of this, there may be slight differences in the way individuals see color. At Konica Minolta, we design and manufacture instruments to measure color, expressing it in a quantifiable way in the same way as a ruler uses numbers to represent dimension. These instruments make it possible for anybody, anywhere to measure color objectively. On the factory floor, in the laboratory or in the farmer’s field, our customers can expect consistent results. Our color and light measuring instruments are accurate and fully traceable. In addition, the measurement data corresponds well with visual assessment, based on the global and exhaustive research of the Commission Internationale de l’Éclairage (CIE). Konica Minolta’s advanced color and light measurement technology helps our customers to increase manufacturing efficiency whilst reducing downtime and material waste. It also helps to improve the perceived consistency and quality of their products.

-

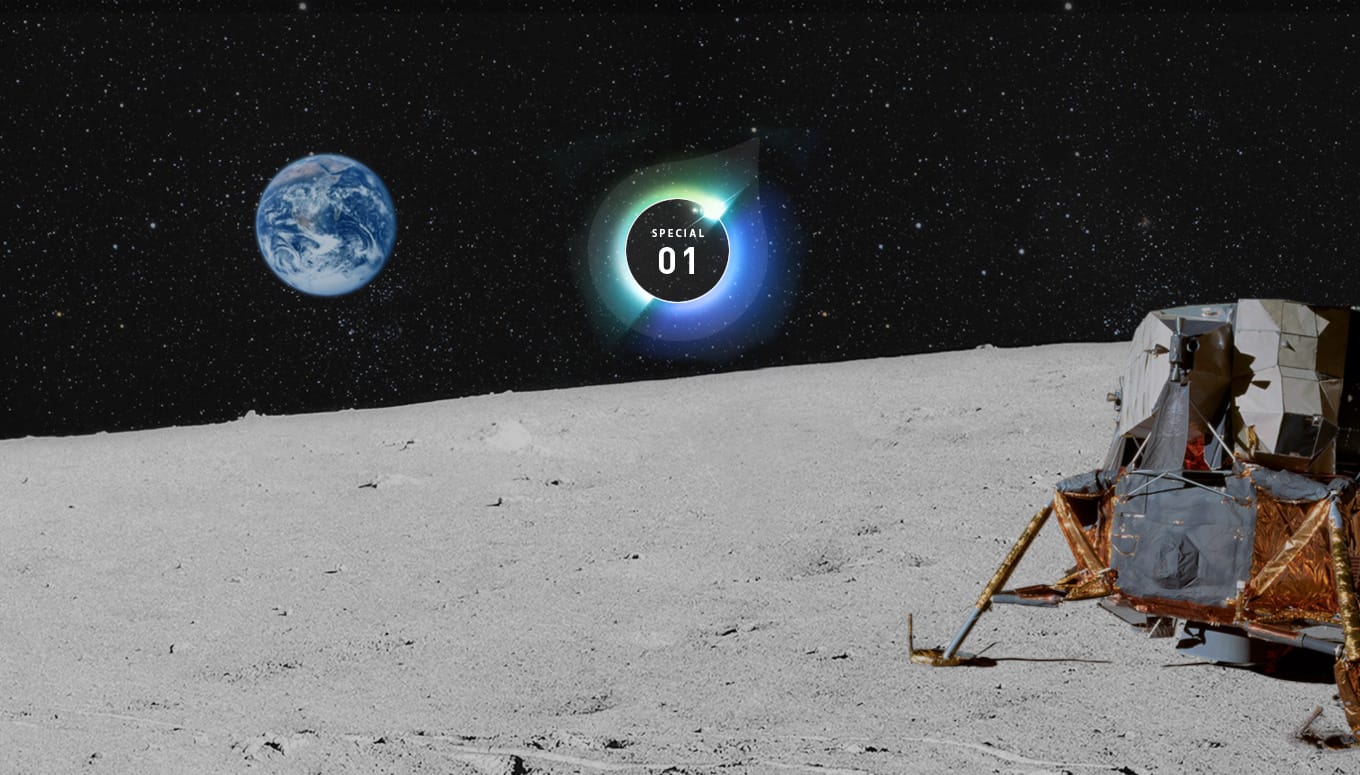

From Point-and Shoot Cameras toOuter SpaceKonica Minolta's introduction into light-measuring technology began as functional designsfor setting camera exposure. Later, the technology was applied to industrial measuringequipment for improving product quality

From Point-and Shoot Cameras toOuter SpaceKonica Minolta's introduction into light-measuring technology began as functional designsfor setting camera exposure. Later, the technology was applied to industrial measuringequipment for improving product quality

-

Light-measuring technology proven all over the world and beyond.Testament to Konica Minolta's expertise in light measurement technology came when NASA asked Konica Minolta todevelop a light measurement instrument. The Minolta Space Meter was used for the first time on the Apollo 8 Mission in1968 and continued to be used on later Missions on to the Moon. Designed for use under extreme conditions, itcontributed to the success of the Apollo program by providing reliable light measurements for photography in outer space.Since the development of this measuring instrument, Konica Minolta has continued to improve its sensors, optics,spectroscopic techniques, and calibration/correction technology to become a global leader in light measurementtechnology.

Light-measuring technology proven all over the world and beyond.Testament to Konica Minolta's expertise in light measurement technology came when NASA asked Konica Minolta todevelop a light measurement instrument. The Minolta Space Meter was used for the first time on the Apollo 8 Mission in1968 and continued to be used on later Missions on to the Moon. Designed for use under extreme conditions, itcontributed to the success of the Apollo program by providing reliable light measurements for photography in outer space.Since the development of this measuring instrument, Konica Minolta has continued to improve its sensors, optics,spectroscopic techniques, and calibration/correction technology to become a global leader in light measurementtechnology.

-

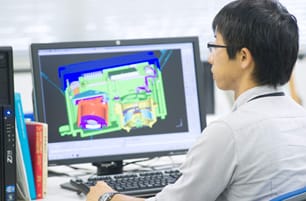

Japan PrideKonica Minolta's products have been created through a finely tuned manufacturing systemdeveloped in Japan. By continually improving its production processes (including an ISO9001 quality management system). Konica Minolta is able to consistently product accurate

Japan PrideKonica Minolta's products have been created through a finely tuned manufacturing systemdeveloped in Japan. By continually improving its production processes (including an ISO9001 quality management system). Konica Minolta is able to consistently product accurate and reliable products.

and reliable products. -

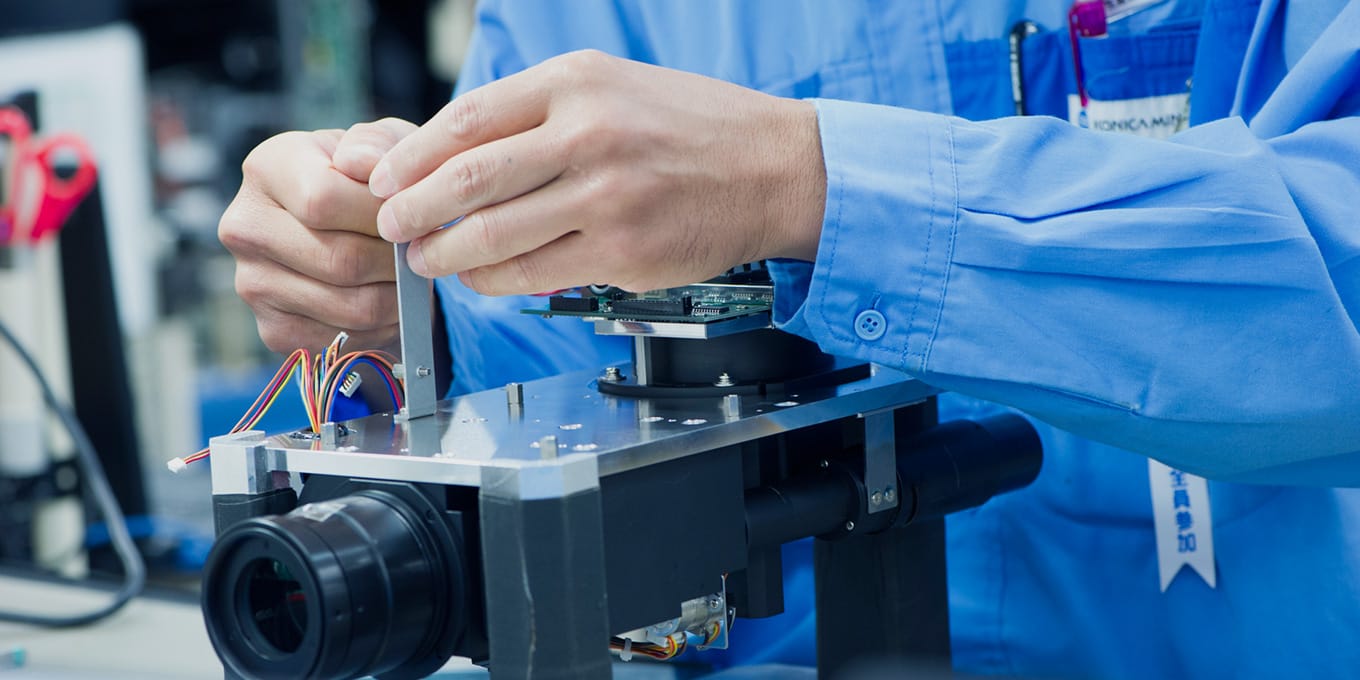

Continuous quality improvement ensures

Continuous quality improvement ensures the highest level of accuracy and reliability.At Konica Minolta, continuous improvement is at the heart of every operation. In manufacturing we have implemented “5S”methodology. Each stage of the production process is scrutinised and optimised to eliminate errors. By encouragingcommunication within the production site, the 5S methodology looks to continuously improve each area and process ofproduction.In order to ensure the best possible accuracy and reliability, we combine the best of automated techniques with handassembly.

the highest level of accuracy and reliability.At Konica Minolta, continuous improvement is at the heart of every operation. In manufacturing we have implemented “5S”methodology. Each stage of the production process is scrutinised and optimised to eliminate errors. By encouragingcommunication within the production site, the 5S methodology looks to continuously improve each area and process ofproduction.In order to ensure the best possible accuracy and reliability, we combine the best of automated techniques with handassembly.

Parts are stored according to theirapplication.All workers are able to accessthe same information via monitors withinthe production environment.The working environment is optimisedto facilitate accurate and efficientoperations.

Parts are stored according to theirapplication.All workers are able to accessthe same information via monitors withinthe production environment.The working environment is optimisedto facilitate accurate and efficientoperations.

-

Reliable Measuring Instruments thatKonica Minolta's products are designed to be easy to use. Maintaining measurementreliability is important. By establishing an uncompromising system of traceability to nationalstandards, Konica Minolta is able to create products that customers can use with

Reliable Measuring Instruments thatKonica Minolta's products are designed to be easy to use. Maintaining measurementreliability is important. By establishing an uncompromising system of traceability to nationalstandards, Konica Minolta is able to create products that customers can use with confidence.are Traceable to National Standards

confidence.are Traceable to National Standards -

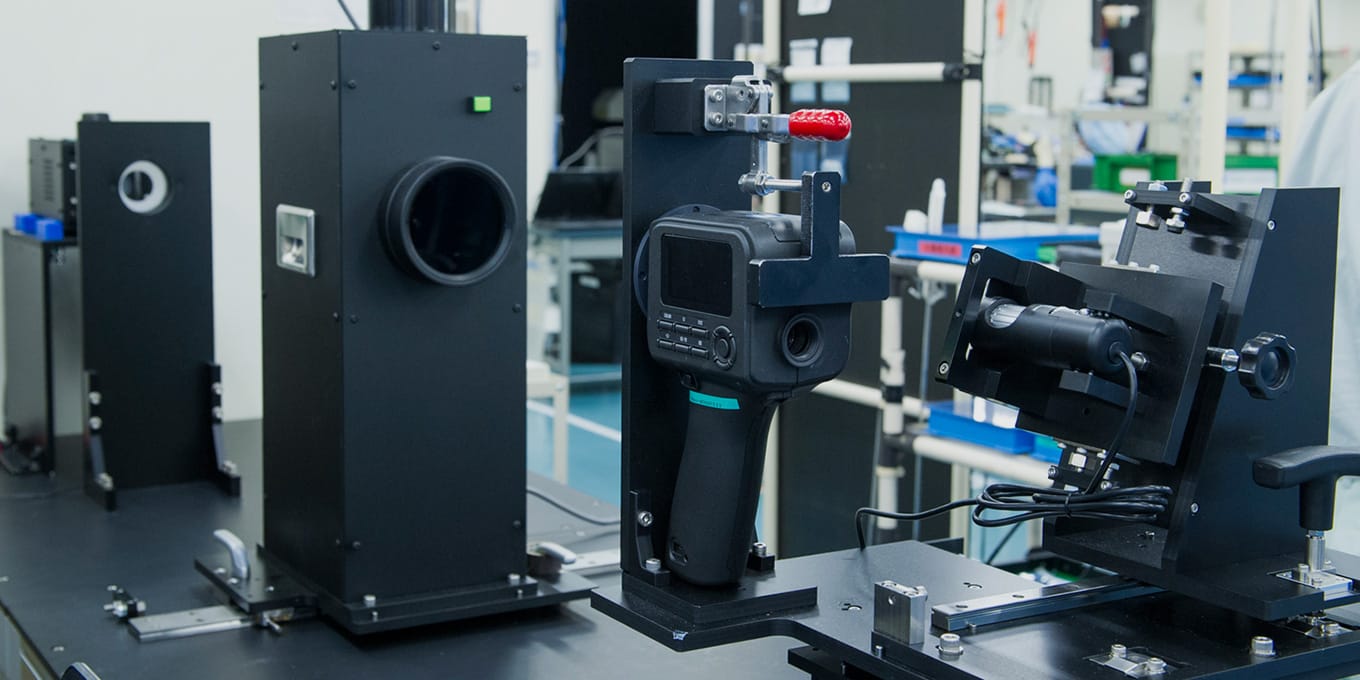

No-compromise manufacturing produces

No-compromise manufacturing produces increased measurement reliability.Konica Minolta places a lot of emphasis on the ability to maintain traceability in the products delivered to customers. Inorder to ensure the measurement reliability of a product, our no-compromise manufacturing process produces measuringinstruments that are traceable to national standards. At Konica Minolta, the standard devices we use for checking colorand light measurements are manufactured in-house. Our light calibration technology conforms to the ISO 17025international standard, and we have been certified as a calibration laboratory. This high-level calibration technology is oneof our technological strengths.

increased measurement reliability.Konica Minolta places a lot of emphasis on the ability to maintain traceability in the products delivered to customers. Inorder to ensure the measurement reliability of a product, our no-compromise manufacturing process produces measuringinstruments that are traceable to national standards. At Konica Minolta, the standard devices we use for checking colorand light measurements are manufactured in-house. Our light calibration technology conforms to the ISO 17025international standard, and we have been certified as a calibration laboratory. This high-level calibration technology is oneof our technological strengths.

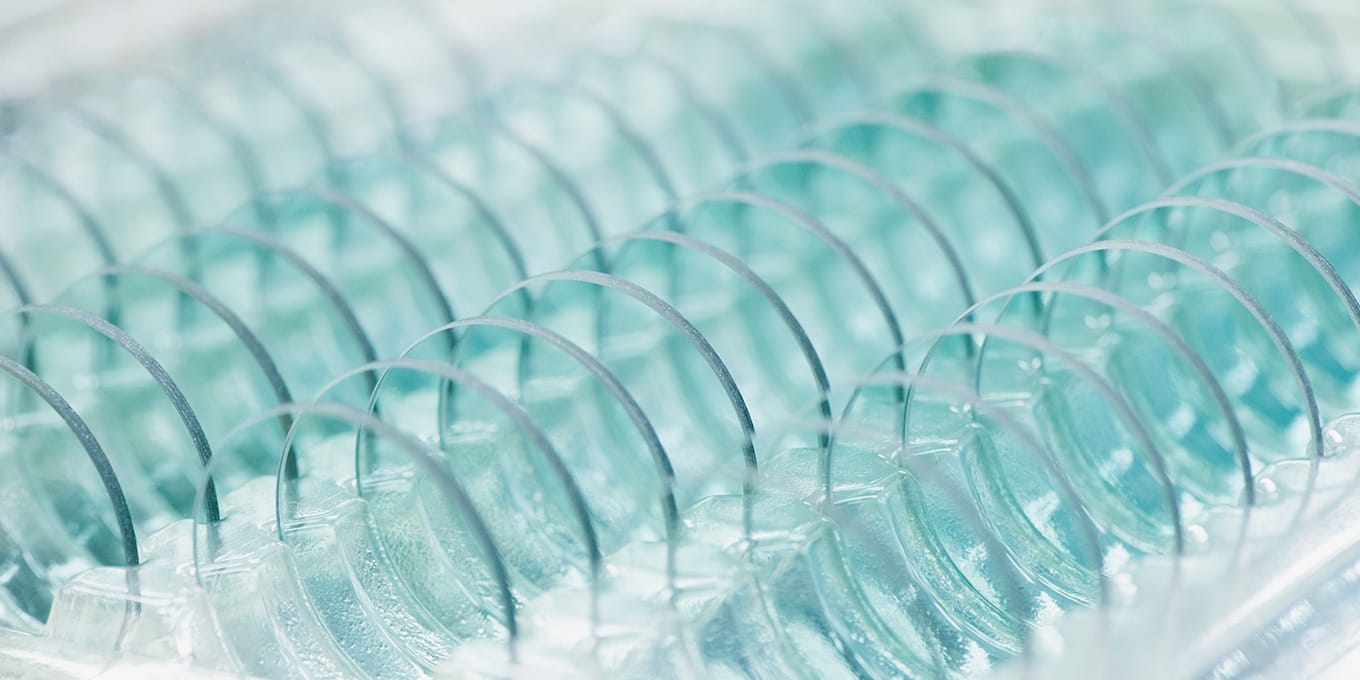

In pursuit of improved quality, coatingof the diffuse reflectors and otherKonica Minolta has obtained ISO 9001certification through LRQA. Thiscertification is a testament to ourColor tiles are used to check thereliability of measuring instruments.Calibration is performed byparts used for measurement isperformed with equipment developedin-house.quality management system thatensures the consistently high qualityof the products and services we offer.experienced technicians.

In pursuit of improved quality, coatingof the diffuse reflectors and otherKonica Minolta has obtained ISO 9001certification through LRQA. Thiscertification is a testament to ourColor tiles are used to check thereliability of measuring instruments.Calibration is performed byparts used for measurement isperformed with equipment developedin-house.quality management system thatensures the consistently high qualityof the products and services we offer.experienced technicians.

-

Looking to Deliver the Best QualityKonica Minolta's goal is to provide reliable products with maximum longevity. This is whywe carry out numerous tests and feed results back to the design to enhance product quality.Our ability to offer such durable measuring equipment is due to our thorough Quality

Looking to Deliver the Best QualityKonica Minolta's goal is to provide reliable products with maximum longevity. This is whywe carry out numerous tests and feed results back to the design to enhance product quality.Our ability to offer such durable measuring equipment is due to our thorough Quality Assurance System.

Assurance System. -

Durable measuring instruments thanks to a thorough

Durable measuring instruments thanks to a thorough product Quality Assurance System.In order to provide customers with products that can be used for a long period of time, they need to be highly durable. Tothat end, Konica Minolta products undergo numerous tests that reflect the needs of the end user and the workingenvironment. Tests include: impact resistance tests for transport, vibration resistance tests, temperature and humiditycompatibility tests, drop tests as well as endurance tests. The test results, customer reports, and service reports aretaken into account for future product design in an effort to create new products with even greater durability.

product Quality Assurance System.In order to provide customers with products that can be used for a long period of time, they need to be highly durable. Tothat end, Konica Minolta products undergo numerous tests that reflect the needs of the end user and the workingenvironment. Tests include: impact resistance tests for transport, vibration resistance tests, temperature and humiditycompatibility tests, drop tests as well as endurance tests. The test results, customer reports, and service reports aretaken into account for future product design in an effort to create new products with even greater durability.

Repair and maintenance is done inspecialized departments, andEnvironmental tests are repeatedlyperformed with consideration given tothe usage conditions all over theRepair data and test results are usedin future product design. This makes itpossible to create new products withinformation is shared in order toensure quality control.world, including high temperatures,low temperatures, and high humidity.even greater reliability.

Repair and maintenance is done inspecialized departments, andEnvironmental tests are repeatedlyperformed with consideration given tothe usage conditions all over theRepair data and test results are usedin future product design. This makes itpossible to create new products withinformation is shared in order toensure quality control.world, including high temperatures,low temperatures, and high humidity.even greater reliability.

-

Worldwide Service, Support andKonica Minolta has service centers located all over the world. These centers areresponsible for providing services to assure customers' instruments remain accurate andtraceable. Since the 1980s, Konica Minolta has sold more than 2 million instruments

Worldwide Service, Support andKonica Minolta has service centers located all over the world. These centers areresponsible for providing services to assure customers' instruments remain accurate andtraceable. Since the 1980s, Konica Minolta has sold more than 2 million instruments through its worldwide network.Expertise

through its worldwide network.Expertise -

A global service network with centers in 25 countries.

A global service network with centers in 25 countries. Konica Minolta’s instruments are designed to provide reliable measurements under a range of conditions, but long-termaccuracy and traceability requires routine maintainance and calibration. With centers in 25 countries, including Japan,USA, Germany, Singapore, China, South Korea, and Taiwan, Konica Minolta’ s service network aims to provide customerswith convenient access to service globally. Establishing service centers throughout the world results in a more efficientand improved provision of service. Konica Minolta continually looks for ways to enhance its service network and provideeven better service to its customers in future. With over 2 million measuring instruments sold, our expertise is ourgreatest asset, enabling us to work with our customers on solutions to complex measurement challenges.

Konica Minolta’s instruments are designed to provide reliable measurements under a range of conditions, but long-termaccuracy and traceability requires routine maintainance and calibration. With centers in 25 countries, including Japan,USA, Germany, Singapore, China, South Korea, and Taiwan, Konica Minolta’ s service network aims to provide customerswith convenient access to service globally. Establishing service centers throughout the world results in a more efficientand improved provision of service. Konica Minolta continually looks for ways to enhance its service network and provideeven better service to its customers in future. With over 2 million measuring instruments sold, our expertise is ourgreatest asset, enabling us to work with our customers on solutions to complex measurement challenges.

-

More than 2 million products sold worldwide. Reliable and proven measuring instruments.

More than 2 million products sold worldwide. Reliable and proven measuring instruments.