คำแนะนำในการวัดด้วยภาพไฮเปอร์สเปกตรัม

การถ่ายภาพไฮเปอร์สเปกตรัม (HSI)เป็นเทคนิคที่ใช้ทั้งสเปกโทรสโกปีและการถ่ายภาพดิจิทัล ที่แบ่งสเปกตรัมออกเป็นหลายแสนแถบ ซึ่งกว้างกว่าที่ตามนุษย์ของเรามองเห็นมาก (สามแถบสีแดง เขียว และน้ำเงิน) รูปภาพจะถูกสร้างขึ้นสำหรับแต่ละแบนด์และเข้ารหัสด้วยระดับสีเทาเพื่อสร้างคิวบ์ข้อมูลไฮเปอร์สเปกตรัมสำหรับการประมวลผลและการวิเคราะห์ ความสามารถเต็มสเปกตรัมของ HSI ช่วยให้สามารถระบุและแยกวัสดุได้อย่างแม่นยำผ่านคุณสมบัติทางกายภาพ ความแตกต่างทางเคมี และทางชีวภาพ

HSI ถูกนำมาใช้มากขึ้นในอุตสาหกรรมต่างๆ และการประยุกต์ใช้ในการวิจัย เช่นสามารถนำไปใช้ศึกษาและตรวจสอบได้อาหารและยาสินค้า, เรียงลำดับของเสียและรีไซเคิลพลาสติก, แผนที่การเจริญเติบโตของพืช สุขภาพ และภาวะโภชนาการ–จำแนกรอยโรคที่ผิวหนังฯลฯ ขั้นตอนแรกสู่โซลูชัน HSI ที่มีประสิทธิผลคือการมีสิทธิ์กล้องไฮเปอร์สเปกตรัมและการตั้งค่า ด้านล่างนี้คือประเด็นที่ควรพิจารณาก่อนตั้งค่าโซลูชัน HSI

ช่วงความยาวคลื่น

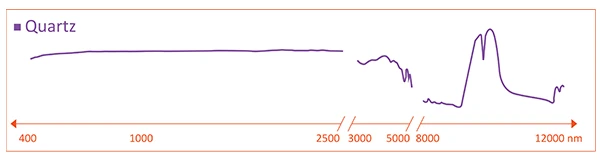

วัสดุและสารประกอบต่างกันจะมีลักษณะทางสเปกตรัม ในช่วงความยาวคลื่นต่างกัน การเลือกกล้อง HSI ควรขึ้นอยู่กับช่วงความยาวคลื่นที่สามารถครอบคลุมและระบุลักษณะสเปกตรัมของเป้าหมายของคุณได้ ดังที่แสดงในรูปที่ 1 แร่ควอตซ์แสดงลักษณะสเปกตรัมยอดและรูปร่างหลัง 8000 นาโนเมตร ดังนั้น กล้อง HSI ที่มีความยาวคลื่น LWIR (อินฟราเรดคลื่นยาว) จึงเหมาะสมกว่า

วิดีโอเพื่อดูข้อมูลเพิ่มเติมเกี่ยวกับวิธีการเลือกกล้อง HSI ที่เหมาะกับการใช้งานของคุณ

การส่องสว่าง

แสงเป็นองค์ประกอบสำคัญใน HSI เนื่องจากส่งผลต่อคุณภาพของภาพไฮเปอร์สเปกตรัม สิ่งแรกที่ต้องพิจารณาคือความแรงของการส่องสว่าง กำลังส่องสว่างที่ต้องการขึ้นอยู่กับระยะห่างระหว่างแหล่งกำเนิดแสงและเป้าหมาย รูปทรงของลำแสงส่องสว่าง และเวลารวมตามอัตราเฟรมและความเร็วของเส้นที่ต้องการ

วิดีโอเพื่อทำความเข้าใจที่มากขึ้น

แสงที่เลือกจะต้องสามารถครอบคลุมความยาวคลื่นของกล้อง HSI ที่คุณใช้อยู่ ด้านล่างนี้เป็นคำแนะนำทั่วไปที่จะช่วยคุณในการเลือกระบบส่องสว่าง

| ช่วงความยาวคลื่น HSI | การส่องสว่าง |

| มองเห็นได้ | · ฮาโลเจน (จุดหรือเชิงเส้น)

· LED · เลเซอร์ซูเปอร์คอนตินิวัม |

| NIR (อินฟราเรดใกล้) | |

| SWIR (อินฟราเรดคลื่นสั้น) | · ฮาโลเจน |

| MWIR (อินฟราเรดคลื่นกลาง) และช่วง LWIR | · ความร้อน |

สิ่งสำคัญคือต้องแน่ใจว่าความเข้มและช่วงสเปกตรัมของการส่องสว่างสม่ำเสมอโดยมีเงาหรือแสงสะท้อนน้อยที่สุด

อัตรารูปภาพและเวลาในการบูรณาการ

สำหรับการใช้งานในการคัดแยกและการตรวจสอบคุณภาพทางอุตสาหกรรม อัตราภาพและเวลาในการบูรณาการเป็นปัจจัยสำคัญที่ต้องพิจารณา นอกเหนือจากขนาดตัวอย่างและความเร็วของสายพานลำเลียง อัตราภาพหมายถึงจำนวนการวัดต่อวินาที ในขณะที่เวลาในการบูรณาการหมายถึงเวลาที่กล้อง HSI ใช้ในการจับโฟตอน สิ่งสำคัญคือต้องทราบว่าเวลาในการผสานรวมกับอัตรารูปภาพควรน้อยกว่าหรือเท่ากับ 1

วิดีโอเพื่อทำความเข้าใจเพิ่มเติมเกี่ยวกับวิธีการกำหนดอัตราภาพที่ถูกต้องสำหรับแอปพลิเคชันของคุณ

นอกจากปัจจัยที่กล่าวมาข้างต้นแล้ว ควรพิจารณาปัจจัยอื่นๆ เช่น ประสิทธิภาพการรวบรวมแสง ฯลฯ ด้วย ตรวจสอบคำแนะนำเพื่อเรียนรู้เพิ่มเติม

หากต้องการทราบข้อมูลเพิ่มเติมเกี่ยวกับ HSI หรือต้องการความช่วยเหลือในการพัฒนาและนำ HSI ไปใช้กับงานที่เหมาะสม สามารถติดต่อเราเพื่อรับคำปรึกษาฟรี