การจำแนกประเภทก้านและใบยาสูบอัตโนมัติด้วยกล้องไฮเปอร์สเปกตรัล SPECIM FX10

ความก้าวหน้าของเทคโนโลยีอัตโนมัติได้เปลี่ยนแปลงวิธีการแปรรูปและจำแนกประเภทวัตถุดิบยาสูบ โดยเฉพาะอย่างยิ่งในการแยกแยะส่วนประกอบของใบและลำต้นซึ่งเป็นตัวกำหนดคุณภาพโดยรวมของผลิตภัณฑ์ วิธีการคัดแยกด้วยมือแบบดั้งเดิม แม้จะมีประสิทธิภาพหากใช้มือผู้มีประสบการณ์ แต่กลับใช้เวลานาน ใช้แรงงานมาก และมีแนวโน้มที่จะเกิดความไม่สอดคล้องกันอันเนื่องมาจากความคิดเห็นส่วนบุคคล เพื่อให้ผ่านข้อจำกัดเหล่านี้ โรงงานแปรรูปสมัยใหม่จึงหันมาใช้โซลูชันที่ใช้เครื่องจักรมากขึ้น ซึ่งผสานรวมระบบถ่ายภาพเข้าด้วยกันเพื่อให้การจำแนกประเภทรวดเร็วขึ้น เชื่อถือได้มากขึ้น หนึ่งในนวัตกรรมที่มีแนวโน้มมากที่สุดคือการถ่ายภาพแบบไฮเปอร์สเปกตรัม (HSI)–

การถ่ายภาพแบบไฮเปอร์สเปกตรัม: โซลูชันไฮเทคสำหรับการคัดแยกยาสูบ

HSI คือเทคโนโลยีการถ่ายภาพขั้นสูงที่ผสานรวมการถ่ายภาพแบบเดิมเข้ากับสเปกโทรสโกปี เพื่อบันทึกข้อมูลสเปกตรัมอย่างละเอียดในช่วงความยาวคลื่นที่กว้างสำหรับทุกพิกเซลในภาพ ต่างจากการถ่ายภาพแบบ RGB หรือการถ่ายภาพแบบหลายสเปกตรัมมาตรฐาน ซึ่งรวบรวมข้อมูลจากแถบสเปกตรัมเพียงไม่กี่แถบ HSI สามารถบันทึกแถบสเปกตรัมที่แคบและต่อเนื่องกันหลายร้อยแถบ ทำให้สามารถระบุองค์ประกอบของวัสดุได้อย่างแม่นยำ รวมถึงความแตกต่างเล็กน้อยในคุณสมบัติทางกายภาพและทางเคมี ในบริบทของการแปรรูปยาสูบ เทคโนโลยี HSI ช่วยทำให้ระบบอัตโนมัติสามารถแยกแยะองค์ประกอบของใบและลำต้นตามลายเซ็นสเปกตรัมที่เป็นเอกลักษณ์เพื่อให้การจำแนกประเภทมีความแม่นยำและความสอดคล้องกันมากขึ้น อำนวยความสะดวกในการควบคุมคุณภาพแบบเรียลไทม์และปรับปรุงกระบวนการในการผลิตยาสูบ

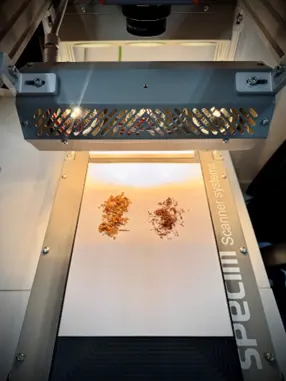

หัวใจสำคัญนี้คือกล้องไฮเปอร์สเปกตรัล Specim FX10eเซ็นเซอร์ถ่ายภาพความเร็วสูงออกแบบมาเพื่อให้มองเห็นได้ไกลเกินกว่าที่สายตามนุษย์จะมองเห็นได้ ทำงานในช่วง 400–1,000 นาโนเมตร จับภาพข้อมูลจากทั้งแสงที่มองเห็นและแสงอินฟราเรดใกล้เผยให้เห็นความแตกต่างเล็กน้อยในองค์ประกอบและโครงสร้างของวัสดุยาสูบ กล้องไฮเปอร์สเปกตรัม FX10e ทำงานควบคู่กับซอฟต์แวร์ Lumo ของ Specimซึ่งทำหน้าที่จัดการการรวบรวมข้อมูล และ SpecimINSIGHT (เวอร์ชัน 1.3.72) ซึ่งประมวลผลข้อมูลสเปกตรัมเพื่อจำแนกวัสดุ โดยก่อให้เกิดระบบ HSI แบบบูรณาการ

ขณะที่ยาสูบเคลื่อนที่ไปตามสายการผลิต กล้องไฮเปอร์สเปกตรัม Specim FX10e จะสแกนและวิเคราะห์ทุกพิกเซลแบบเรียลไทม์อย่างต่อเนื่อง โดยไม่สัมผัสหรือสร้างความเสียหายให้กับผลิตภัณฑ์ ซึ่งทำให้ระบบ HSI สามารถแยกแยะใบยาสูบจากก้านได้ทันทีด้วยการตรวจจับลายเซ็นสเปกตรัมเฉพาะตัว ผลลัพธ์ที่ได้คือเวิร์กโฟลว์ที่ราบรื่นและทำงานอัตโนมัติเต็มรูปแบบ ซึ่งแทนที่การคัดแยกด้วยมือที่ใช้เวลานาน ด้วยโซลูชันที่รวดเร็ว แม่นยำ และขับเคลื่อนด้วยข้อมูลมากขึ้น จึงมั่นใจได้ว่ายาสูบทุกล็อตมีคุณภาพตรงตามที่ต้องการ

หลักฐานแนวคิด: การแยกก้านและใบอย่างชัดเจน

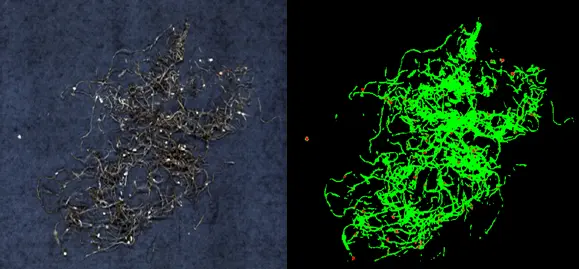

ผลการจำแนกประเภทไฮเปอร์สเปกตรัมเผยให้เห็นความแตกต่างทางสายตาที่ชัดเจน โดยลำต้นและใบยาสูบปรากฏเป็นสีแดงและสีเขียวตามลำดับ เมื่อใช้กล้องไฮเปอร์สเปกตรัม Specim FX10e ร่วมกับซอฟต์แวร์ SpecimINSIGHTการทดสอบพิสูจน์แนวคิดนี้ประสบความสำเร็จในการทดสอบการแยกลำต้นและใบโดยอัตโนมัติ ดังที่แสดงในภาพสีเทียมด้านบน รหัสสีไม่ได้ถูกใส่คำอธิบายประกอบด้วยตนเอง แต่สร้างขึ้นโดยแบบจำลองของระบบ HSI เอง ซึ่งได้รับการฝึกฝนให้รับรู้ความแตกต่างของสเปกตรัมที่ละเอียดอ่อนระหว่างวัสดุทั้งสองชนิด

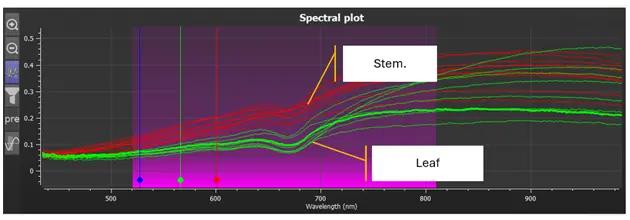

การค้นพบที่น่าสนใจอย่างหนึ่งจากการทดสอบนี้คือ ความแตกต่างของการสะท้อนแสงระหว่างใบยาสูบและลำต้นมีความสำคัญมากที่สุดในช่วงความยาวคลื่น 520–810 นาโนเมตร ในช่วงแสงสีเขียวถึงอินฟราเรดใกล้ ลำต้นยาสูบจะสะท้อนแสงได้มากกว่าใบยาสูบอย่างสม่ำเสมอ ทำให้ระบบมีลายเซ็นสเปกตรัมที่เชื่อถือได้สำหรับการใช้งาน กล้องไฮเปอร์สเปกตรัม Specim FX10e สามารถบันทึกความผันแปรเหล่านี้ได้อย่างละเอียด ขณะที่ SpecimINSIGHT วิเคราะห์ข้อมูลทันทีเพื่อจำแนกแต่ละพิกเซลแบบทันที

ยิ่งไปกว่านั้น แม้แต่ในตัวอย่างผสมที่ซับซ้อนซึ่งใบและลำต้นดูเกือบจะเหมือนกันทุกประการด้วยตาเปล่า ระบบ HSI ก็ยังระบุตำแหน่งของใบและลำต้นได้อย่างแม่นยำ ความสามารถในการแยกแยะวัสดุโดยใช้ลายนิ้วมือสเปกตรัมนี้ ช่วยให้สามารถคัดแยกได้โดยอัตโนมัติแบบเรียลไทม์ ทันทีที่กล้องสแกนใบยาสูบ ซอฟต์แวร์จะระบุและติดฉลากก้านและใบ ทำให้ได้ข้อมูลที่แม่นยำ ซึ่งสามารถสั่งการให้เครื่องคัดแยกอัตโนมัติดำเนินการประมวลผลอย่างต่อเนื่องและไม่ต้องใช้มือตลอดสายการผลิต

การปรับปรุงการควบคุมคุณภาพยาสูบด้วยระบบอัตโนมัติ

การนำ HSI มาใช้ในกระบวนการคัดแยกวัสดุยาสูบ ช่วยให้ผู้ผลิตพัฒนาการตรวจสอบให้มีความสม่ำเสมอ ความแม่นยำ และประสิทธิภาพในการดำเนินงาน ระบบ HSI แบบบูรณาการของ Specim FX10e มอบข้อได้เปรียบสำคัญหลายประการ:

- การตรวจสอบแบบไม่ต้องสัมผัสแบบเรียลไทม์:ระบบ HSI สแกนวัตถุดิบยาสูบโดยตรงบนสายพานลำเลียงด้วยความเร็วการผลิตสูงสุดโดยไม่ต้องสัมผัสโดยตรง สามารถแยกก้านและใบยาสูบในทุกเฟรมได้ทันที

- การจำแนกประเภทลำต้นและใบอย่างแม่นยำ:โมเดลการเรียนรู้ของเครื่องขั้นสูงจะวิเคราะห์ลายเซ็นสเปกตรัมเฉพาะของวัสดุแต่ละชนิดเพื่อระบุลำต้นและใบได้อย่างแม่นยำ ช่วยให้จัดหมวดหมู่ได้แม่นยำก่อนดำเนินการประมวลผลในภายหลัง

- การควบคุมกระบวนการที่สม่ำเสมอ:การวิเคราะห์สเปกตรัมอัตโนมัติช่วยรักษาอัตราส่วนใบต่อลำต้นที่ต้องการ สนับสนุนคุณภาพวัสดุที่สม่ำเสมอและความสม่ำเสมอของส่วนผสมตลอดการผลิต

- ลดข้อผิดพลาดด้วยตนเอง:ระบบอัตโนมัติช่วยลดการพึ่งพาการจัดเรียงภาพด้วยมือ ทำให้ลดข้อผิดพลาดในการให้คะแนน ความต้องการแรงงาน และความแปรปรวนระหว่างผู้ปฏิบัติงานได้อย่างมาก ซึ่งช่วยปรับปรุงประสิทธิภาพของกระบวนการโดยรวม

- ระบบพร้อมบูรณาการ:สามารถเชื่อมต่อเอาต์พุตการจำแนกประเภท HSI เข้ากับตัวกระตุ้นหรือกลไกการเรียงลำดับบนสายการผลิตได้อย่างราบรื่น ช่วยให้บูรณาการเข้ากับระบบที่มีอยู่ได้อย่างง่ายดาย และรองรับการเรียงลำดับและแยกวัสดุอัตโนมัติเต็มรูปแบบสำหรับการแปรรูปยาสูบ

โซลูชันการถ่ายภาพไฮเปอร์สเปกตรัมแบบสเปกซิม

กล้องไฮเปอร์สเปกตรัล Specim FX10 และ SpecimINSIGHT

Specim ซึ่งเป็นส่วนหนึ่งของกลุ่มบริษัท Konica Minolta เป็นผู้นำระดับโลกด้านเทคโนโลยี HSI นำเสนอโซลูชันการถ่ายภาพขั้นสูงสำหรับการใช้งานในภาคอุตสาหกรรมและการวิจัย ด้วยความเชี่ยวชาญด้านการถ่ายภาพแบบสเปกตรัมที่สั่งสมมานานหลายทศวรรษ เทคโนโลยีของ Specim ช่วยให้สามารถระบุวัสดุ จำแนกประเภท และตรวจสอบคุณภาพได้อย่างแม่นยำในหลากหลายอุตสาหกรรม

นอกจาก กล้องไฮเปอร์สเปกตรัล Specim FX10e, Specim ยังมี ผลิตภัณท์ที่กว้างขวาง ในหลายโซลูชันของไฮเปอร์สเปกตรัมที่ครอบคลุมช่วงความยาวคลื่นหลายช่วง ตั้งแต่ช่วงแสงที่มองเห็นได้และอินฟราเรดใกล้ (VNIR) ไปจนถึงอินฟราเรดคลื่นแบบสั้น (SWIR) อินฟราเรดคลื่นแบบกลาง (MWIR) และอินฟราเรดคลื่นแบบยาว (LWIR) โซลูชันเหล่านี้ประกอบด้วยระบบไฮเปอร์สเปกตรัมแบบอินไลน์และแบบลอยตัวในอากาศ ซึ่งออกแบบมาสำหรับการใช้งานต่างๆ เช่นเกษตรกรรม–คุณภาพและความปลอดภัยของอาหาร–การผลิตยา–การรีไซเคิลและการตรวจสอบวัตถุดิบอุตสาหกรรม

หากสนใจเรียนรู้เพิ่มเติมเกี่ยวกับระบบ Specim FX10e HSI หรือต้องข้อมูลในการการผนวกรวมเทคโนโลยี HSI เข้ากับการดำเนินงานผลิตของคุณเพื่อการควบคุมคุณภาพที่ชาญฉลาดและขับเคลื่อนด้วยข้อมูล สามารถติดต่อเราได้วันนี้เพื่อค้นพบว่า Konica Minolta Sensing และ Specim สามารถช่วยปรับปรุงกระบวนการผลิตของคุณด้วยโซลูชัน HSI ได้อย่างไร