การควบคุมคุณภาพสีของถุงมือยางธรรมชาติ

คุณภาพมักเกี่ยวข้องกับความสม่ำเสมอ และถุงมือยางก็ไม่มีข้อยกเว้น ด้วยการเน้นย้ำถึงความสำคัญของถุงมือที่ใช้รหัสสีมากขึ้น ความสม่ำเสมอของสีสำหรับถุงมือจึงเข้มงวดมากขึ้น ผู้ผลิตหลายรายในอุตสาหกรรม เช่น การดูแลสุขภาพและอาหารกำลังเปลี่ยนมาใช้ระบบค่าตัวเลขผ่านเครื่องมือวัดสีเพื่อให้แน่ใจว่าสีมีความสม่ำเสมอ

ด้วยความช่วยเหลือของเครื่องมือวัดสีที่ได้มาตรฐานกระบวนการควบคุมสีสามารถจัดตั้งขึ้นเพื่อช่วยให้ผู้ผลิตตรงตามมาตรฐานคุณภาพสีพร้อมทั้งลดข้อผิดพลาดและของเสีย

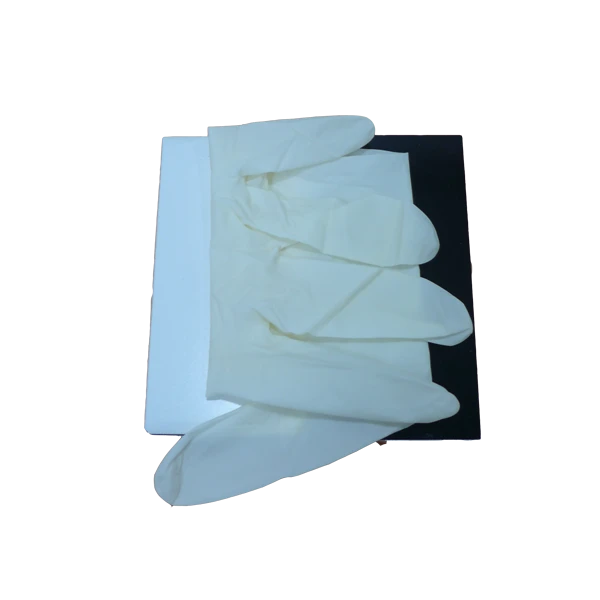

ถุงมือส่วนใหญ่ไม่ได้ทึบแสงเต็มที่ และแนะนำให้พับถุงมือหลายทบเพื่อให้แน่ใจว่ามีความทึบก่อนที่จะนำเสนอเพื่อการวัดสี สำหรับถุงมือที่มีความโปร่งแสงสูง แนะนำให้ใช้การวัดแสงสะท้อนโดยใช้แผ่นรองซับสเตรตสีขาว กระเบื้องเซรามิคหรือการ์ดทึบแสง Leneta เป็นวัสดุพิมพ์สองชนิดที่ใช้กันทั่วไป

ดัชนีความทึบหรือความทึบของถุงมือยางสามารถกำหนดได้โดยการแบ่งแสงสะท้อนของถุงมือที่มีซับสเตรตสีดำ กับแสงสะท้อนของถุงมือเดียวกันที่มีซับสเตรตสีขาวหนุนหลัง ยิ่งถุงมือมีความโปร่งใสมากเท่าใด ดัชนีความทึบก็จะยิ่งน้อยลงเท่านั้น

| ไม่มีพับ | ค่า L* |

| เหนือพื้นผิวสีดำ | 78.5 |

| บนพื้นผิวสีขาว | 90.2 |

| สองเท่า | ค่า L* |

| เหนือพื้นผิวสีดำ | 86.1 |

| บนพื้นผิวสีขาว | 88.7 |

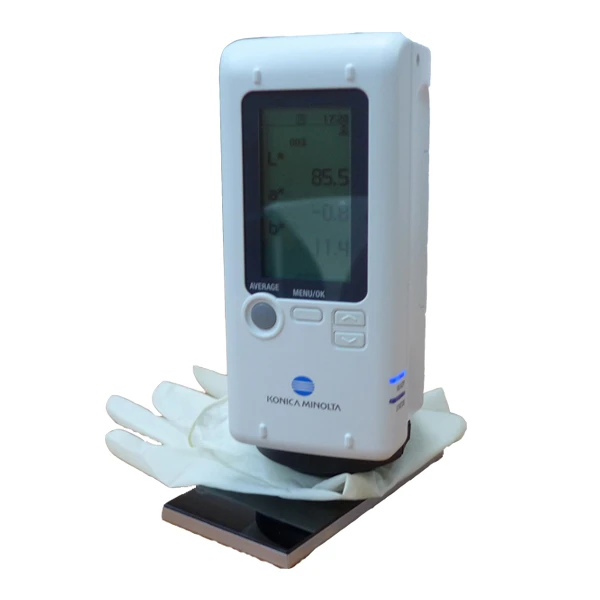

เครื่องมือวัดสีเช่นเครื่องอ่านสี Konica Minolta CR-20มีปริภูมิสีที่จำเป็น เช่นCIE L*a*b*และเย้เพื่อการประเมินสีที่รวดเร็ว ง่ายดาย และเป็นกลาง CR-20 พกพาสะดวกและใช้งานง่าย เหมาะสำหรับการประเมินสีที่ไซต์งาน และมักนำไปใช้ในกระบวนการถุงมือยางธรรมชาติทั้งระหว่างดำเนินการหรือส่งออก เพื่อเป็นมาตรวัดผ่าน/ไม่ผ่านอย่างง่าย

เรียนรู้เพิ่มเติมเกี่ยวกับการควบคุมคุณภาพสีของถุงมือยางที่นี่–

หรือคลิกที่นี่หรือโทรหาเราที่ (+65) 6563 5533 เพื่อปรึกษาผู้เชี่ยวชาญด้านสีของเรา