การวัดไฟ LED ขนาดเล็ก – MicroLED

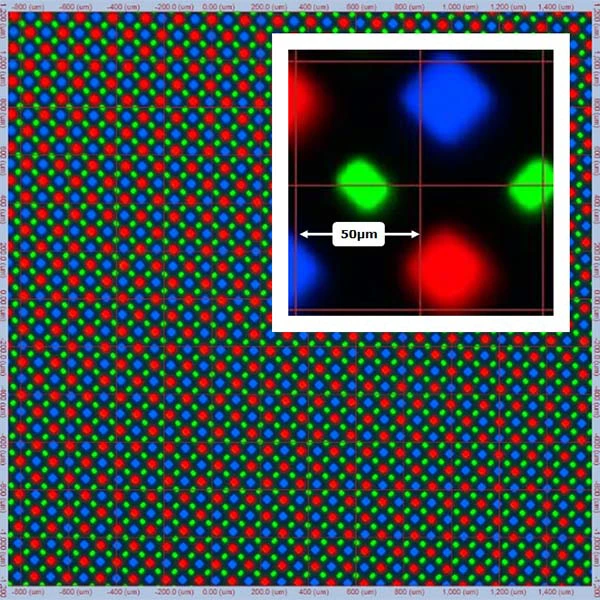

MicroLED (µLED) เป็นเทคโนโลยีการแสดงผลที่เกิดขึ้นใหม่พร้อมคุณสมบัติที่โดดเด่น เช่น อัตราส่วนคอนทราสต์สูง ขอบเขตสีที่กว้าง การใช้พลังงานต่ำ และอายุการใช้งานยาวนาน โดยทั่วไปแล้ว microLED หนึ่งตัวจะวัดได้น้อยกว่า 100 ไมโครเมตร (µm) หรือประมาณ 1/100 ของขนาดของ LED ทั่วไป MicroLED มีคุณลักษณะหลายประการร่วมกันOLEDเทคโนโลยี; เปล่งแสงได้เองและไม่ต้องใช้แสงไฟ แต่ต่างจาก OLED ตรงที่ใช้วัสดุอนินทรีย์แกลเลียมไนไตรด์ (GaN) เพื่อสร้างแสงในตัวมันเอง ซึ่งจะช่วยลดความจำเป็นในการห่อหุ้มและชั้นโพลาไรซ์ ทำให้แผงจอแสดงผลบางลง สำหรับการใช้งานที่ต้องการความสว่างและประสิทธิภาพเช่นนาฬิกาอัจฉริยะ, จอแสดงผลบนกระจกหน้า (HUD), ความเป็นจริงเสมือน (VR) หรือชุดหูฟังความเป็นจริงเสริม (AR) การใช้เทคโนโลยี microLED เหมาะอย่างยิ่ง

แม้ว่าประสิทธิภาพจะมีแนวโน้มที่ดี แต่เทคโนโลยี microLED ก็ยังไม่มีการจำหน่ายในเชิงพาณิชย์ ยังคงมีความท้าทายด้านการผลิตหลายประการที่ต้องแก้ไข และความท้าทายประการหนึ่งก็คือเทคโนโลยีการทดสอบและการตรวจสอบ เนื่องจากขนาดที่เล็กและชิป microLED จำนวนมหาศาลที่ต้องใช้ในการสร้างจอแสดงผล การใช้อุปกรณ์ทดสอบแบบเดิมๆ จึงไม่เหมาะสม

โคนิก้า มินอลต้า พร้อมด้วยกลุ่มบริษัท Radiant Vision Systems นำเสนอข้อเสนอโซลูชั่นการประเมินผลการแสดงผลเช่นเครื่องวิเคราะห์สีจอแสดงผล CA-410โพรบเฉพาะจุดขนาดเล็กและโฟโตมิเตอร์/คัลเลอริมิเตอร์ ProMetricที่ช่วยให้ผู้ใช้ทดสอบและตรวจสอบประสิทธิภาพของจอแสดงผล microLED ได้อย่างง่ายดาย

การทดสอบประสิทธิภาพการแสดงผลทั่วไปประกอบด้วย:

- การวัดความสว่าง สี และความสม่ำเสมอ

- สมดุลสีขาวการปรับ/การตรวจสอบ

- แกมมา/การปรับ/การตรวจสอบระดับสีเทา

- การวัด/การปรับการสั่นไหว

- ขอบเขตสีการวัด

- ความแปรผันของการประเมินมุมมอง

- การประเมินเอฟเฟกต์ประกายไฟป้องกันแสงสะท้อน

- การตรวจจับข้อบกพร่องของพิกเซล

หากต้องการความช่วยเหลือในการทดสอบและตรวจสอบจอแสดงผลที่มีพิกเซลหนาแน่นและเปล่งแสง เช่น OLED และ microLED สามารถติดต่อกับเราเพื่อนัดหมายการให้คำปรึกษาฟรีหรือการสาธิตผลิตภัณฑ์