การวัดพื้นผิวของการฉีดขึ้นรูป

ลักษณะพื้นผิวความสม่ำเสมอเป็นเกณฑ์สำคัญประการหนึ่งของพลาสติกคุณภาพของผลิตภัณฑ์. พื้นผิวของผลิตภัณฑ์พลาสติกควรเป็นเนื้อเดียวกันหลังการขึ้นรูป โดยไม่มีแถบมันวาวและหมองคล้ำสลับกันที่มองเห็นได้บนพื้นผิว ปัจจัยหนึ่งที่อาจนำไปสู่ผลกระทบที่ไม่พึงประสงค์นี้คือพื้นผิวของเครื่องมือขึ้นรูป

พื้นผิวของโพรงแม่พิมพ์และแกนมีอิทธิพลต่อคุณภาพพื้นผิวของชิ้นส่วนพลาสติกที่ขึ้นรูป เนื้อสัมผัสสามารถวัดปริมาณได้ด้วยความมันวาวโดยค่าความเงาสูงจะบ่งบอกถึงพื้นผิวที่เรียบ เนื่องจากแม่พิมพ์มีหลายรูปทรงและขนาด การใช้เครื่องวัดความเงาแบบธรรมดาจึงไม่เหมาะ เนื่องจากส่วนใหญ่ได้รับการออกแบบมาเพื่อวัดพื้นผิวขนาดใหญ่และเรียบ

โคนิก้า มินอลต้า ร่วมมือกับ Rhopoint เพื่อนำเสนอโซลูชั่นที่สมบูรณ์แบบสำหรับการใช้งานเหล่านี้ด้วยNovo-Gloss Flex 60เครื่องวัดความเงา ออกแบบมาพร้อมกับหัววัดภายนอก จึงสามารถวัดความเงาในพื้นที่ขนาดเล็กของคาวิตี้และพื้นผิวแกนซึ่งไม่สามารถวัดด้วยมิเตอร์วัดความเงาทั่วไปได้ อะแดปเตอร์ของหัววัดทำจากพลาสติก เหมาะสำหรับเครื่องมือขึ้นรูปพื้นผิวที่ไวต่อรอยขีดข่วน

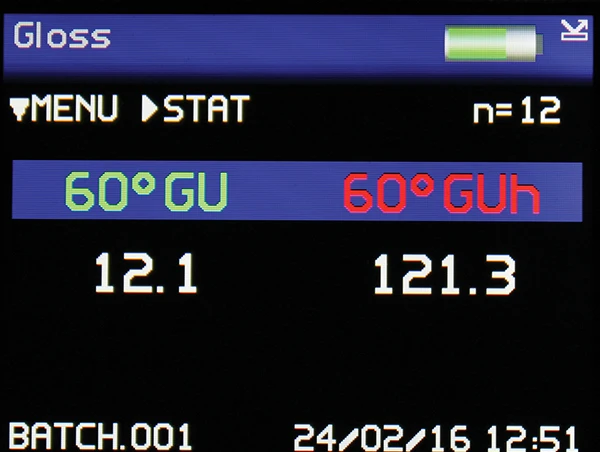

Novo-Gloss Flex 60 มีอะแดปเตอร์สำหรับการวัดแบบเปลี่ยนได้: อะแดปเตอร์มาตรฐานและอะแดปเตอร์พื้นผิวเหล็กสำหรับวัสดุที่เป็นเหล็ก มีช่วงการวัดเพิ่มเติมของ GUh ที่มีความละเอียดสูงกว่าในการวัดพื้นผิวมันวาวต่ำ (0-12 GU)

เรียนรู้เพิ่มเติมเกี่ยวกับการวัดลักษณะภายนอกกับเรากระดาษสีขาว–

หรือติดต่อเราที่นี่หรือติดต่อเราที่ (+65) 6563 5533 เพื่อขอคำปรึกษาฟรีหรือนัดหมายการสาธิต