การควบคุมสีที่สม่ำเสมอในผลิตภัณฑ์เซรามิกด้วยเครื่องวัดสเปกตรัม

อุตสาหกรรมเซรามิกเป็นภาคการผลิตที่ขับเคลื่อนด้วยสุนทรียภาพ ซึ่ง “สี” มีบทบาทสำคัญในการสร้างความน่าดึงดูดใจและสะท้อนคุณภาพของผลิตภัณฑ์ ตั้งแต่กระเบื้องตกแต่งไปจนถึงเครื่องครัวและสุขภัณฑ์ ความสม่ำเสมอของสีถือเป็นองค์ประกอบสำคัญที่มีผลโดยตรงต่อความพึงพอใจของลูกค้าและการรักษามาตรฐานระดับอุตสาหกรรม อย่างไรก็ตาม การควบคุมให้สีมีความสม่ำเสมอในทุกล็อตการผลิตยังคงเป็นความท้าทาย เนื่องจากปัจจัยแปรผันหลายประการ เช่น ความไม่สม่ำเสมอของวัตถุดิบ เงื่อนไขในกระบวนการขึ้นรูป การเคลือบ รวมถึงอุณหภูมิและสภาพแวดล้อมในเตาเผา ความแตกต่างเพียงเล็กน้อยในขั้นตอนเหล่านี้สามารถส่งผลให้สีของผลิตภัณฑ์เปลี่ยนแปลงไปอย่างชัดเจน ทำให้การควบคุมคุณภาพสีเป็นรากฐานที่สำคัญของการผลิตเซรามิก

โดยทั่วไปแล้ว การตรวจสอบสีในอุตสาหกรรมเซรามิกมักอาศัยการประเมินด้วยสายตาเป็นหลัก แม้จะเป็นวิธีที่เรียบง่ายและใช้ได้จริงในหลายกรณี แต่แนวทางนี้มีความเป็นอัตวิสัยสูง และมีความเสี่ยงต่อความไม่สม่ำเสมอจากปัจจัยภายนอก เช่น สภาพแสง การรับรู้ของผู้ประเมิน และความล้าของสายตา ความแปรปรวนเหล่านี้อาจนำไปสู่ความแตกต่างของสีระหว่างล็อตการผลิต ซึ่งกระทบต่อคุณภาพและความสม่ำเสมอของผลิตภัณฑ์ เพื่อแก้ไขปัญหานี้ ผู้ผลิตเซรามิกจำนวนมากจึงเริ่มหันมาใช้เครื่องวัดสีขั้นสูง เช่น สเปกโตรโฟโตมิเตอร์ (Spectrophotometer) ซึ่งสามารถให้ข้อมูลเชิงปริมาณเกี่ยวกับค่าความต่างของสี (ΔE) ได้อย่าง แม่นยำ เป็นกลาง และทำซ้ำได้

การวัดสีเชิงวัตถุในอุตสาหกรรมเซรามิก

เครื่องวัดสเปกตรัม เป็นเครื่องมือที่ใช้วัดคุณลักษณะของสีบนพื้นผิววัสดุอย่างแม่นยำ โดยทำงานผ่านการวัดพฤติกรรมของแสงที่สะท้อนหรือส่งผ่านพื้นผิว เครื่องมือจะฉายลำแสงที่ถูกควบคุมอย่างแม่นยำไปยังวัสดุ และตรวจจับแสงที่สะท้อนกลับหรือทะลุผ่านในช่วงความยาวคลื่นต่างๆ ซึ่งผลลัพธ์จะถูกแปลงเป็นข้อมูลเชิงสเปกตรัม หรือที่เรียกว่า สเปกตรัมรีเฟล็กแทนซ์ ข้อมูลสเปกตรัมนี้แสดงลักษณะเฉพาะของสีในรูปแบบของเส้นโค้งความยาวคลื่น ซึ่งเป็นรากฐานในการวิเคราะห์สีอย่างละเอียด จากข้อมูลดังกล่าว เครื่องมือจะคำนวณค่ากระตุ้นสามระดับ ได้แก่ X, Y และ Z ตามระบบของ CIE

ค่าทั้งสามนี้สามารถนำไปแปลงเป็น ค่าพื้นที่สีมาตรฐาน CIE L*a*b* ซึ่งเป็นรูปแบบการแสดงค่าสีในเชิงปริมาณที่นิยมใช้กันอย่างแพร่หลายในอุตสาหกรรม เนื่องจากสามารถระบุความแตกต่างของสี (ΔE) ได้อย่างชัดเจนและทำการวัดซ้ำได้

ระบบสี CIE L*a*b* เป็นหนึ่งในพื้นที่สีที่ได้รับความนิยมและใช้กันอย่างแพร่หลายในอุตสาหกรรม เนื่องจากสามารถให้การวัดสีที่เป็นกลาง เป็นมาตรฐานสากล และเชื่อถือได้ โดยระบบนี้แสดงสีทั้งหมดในลักษณะของ พื้นที่สีสามมิติ (three-dimensional color space) ซึ่งอิงตามการรับรู้ของสายตามนุษย์ คือ แกน L* แสดงค่าความสว่าง (Lightness) มีค่าตั้งแต่ 0 (ดำ) ถึง 100 (ขาว) แกน a* วัดความเอนเอียงของสีในแนว แดง (+) ถึง เขียว (−) และ แกน b* วัดความเอนเอียงของสีในแนว เหลือง (+) ถึง น้ำเงิน (−) ด้วยค่าทั้งสามนี้ ผู้ผลิตสามารถกำหนดและตรวจสอบได้ว่าสีของผลิตภัณฑ์ เช่น เซรามิก หรือวัสดุตกแต่งต่างๆ สอดคล้องกับข้อกำหนดมาตรฐานหรือไม่ หากพบความเบี่ยงเบนของสี (ΔE) ก็สามารถวิเคราะห์และปรับกระบวนการผลิตให้กลับคืนสู่ค่าที่ต้องการได้อย่างมีประสิทธิภาพ

การควบคุมคุณภาพสีเซรามิกด้วยเครื่องวัดสเปกตรัม

การควบคุมสีให้สม่ำเสมอในผลิตภัณฑ์เซรามิกเริ่มต้นตั้งแต่ขั้นตอนแรกของกระบวนการผลิต นั่นคือ การประเมินวัตถุดิบหลัก เช่น ดินเหนียว ซิลิกา ควอตซ์ เฟลด์สปาร์ และเซอร์โคเนียม ซึ่งล้วนมีอิทธิพลต่อสีของผลิตภัณฑ์เมื่อผ่านการเผา เครื่องสเปกโตรโฟโตมิเตอร์ มีบทบาทสำคัญในกระบวนการนี้ โดยสามารถวัดค่าสีของวัตถุดิบได้อย่างแม่นยำและเชื่อถือได้ เพื่อให้มั่นใจว่าวัสดุแต่ละชุดเป็นไปตามข้อกำหนดที่กำหนดไว้และอยู่ในช่วงค่าที่สามารถยอมรับได้

เนื่องจากวัตถุดิบเหล่านี้มีแนวโน้มจะเปลี่ยนแปลงคุณสมบัติเมื่อผ่านการเผา ผู้ผลิตจึงมักสร้างตัวอย่าง บิสก์ เซรามิกที่ผ่านการเผาแต่ยังไม่เคลือบ เพื่อตรวจสอบคุณภาพสีเบื้องต้น หากพบความแตกต่างของสี ข้อมูลที่ได้จากการวัดจะช่วยให้สามารถดำเนินการแก้ไข เช่น การปรับสูตรโดยเติมเม็ดสีเพิ่มเติม เพื่อชดเชยความคลาดเคลื่อน

แม้ว่าจะมีการควบคุมวัตถุดิบอย่างเข้มงวดแล้ว กระบวนการเผาเองก็ยังเป็นตัวแปรที่มีผลอย่างมากต่อสีขั้นสุดท้าย ปัจจัยต่างๆ เช่น อุณหภูมิ เวลาในการเผา และการกระจายความร้อนในเตาเผา ล้วนสามารถส่งผลต่อการเปลี่ยนแปลงของสีได้อย่างชัดเจน

ด้วยการใช้เครื่องสเปกโตรโฟโตมิเตอร์ในขั้นตอนหลังการเผา ผู้ผลิตสามารถตรวจสอบความเปลี่ยนแปลงของสีได้อย่างเป็นระบบ โดยสามารถเชื่อมโยงค่าที่วัดได้กับสภาวะการเผา และใช้ข้อมูลดังกล่าวเพื่อปรับกระบวนการผลิตให้ได้ผลลัพธ์ที่สม่ำเสมอและเป็นไปตามมาตรฐาน

ขั้นตอนสุดท้ายของการควบคุมคุณภาพสีเน้นที่การรับประกันความสม่ำเสมอในผลิตภัณฑ์เซรามิกสำเร็จรูป ในขั้นตอนนี้ เครื่องวัดสเปกตรัมมีความจำเป็นสำหรับการตรวจยืนยันว่าสีสุดท้ายตรงตามข้อกำหนดที่ต้องการ ลดความแตกต่างระหว่างชุดผลิตภัณฑ์ และรับรองความสอดคล้องกับมาตรฐานอุตสาหกรรม เซรามิกเคลือบมีความท้าทายเพิ่มเติมเนื่องจากปฏิสัมพันธ์ระหว่างเคลือบและตัวเซรามิกด้านล่าง เคลือบส่งผลต่อสีสุดท้ายและส่งผลต่อการสะท้อนแสง ทำให้การรับรู้สีเปลี่ยนไป เพื่อแก้ไขปัญหานี้ เครื่องวัดสเปกตรัมด้วยSCI (รวมส่วนประกอบแบบสะท้อนแสง) และ SCE (ไม่รวมส่วนประกอบแบบสะท้อนแสง)โหมดควบคู่ไปกับการวัดความเงาขอแนะนำเครื่องมือเหล่านี้สามารถจับภาพสีจริงและระดับความเงาได้ ทำให้ประเมินเซรามิกเคลือบได้อย่างแม่นยำ

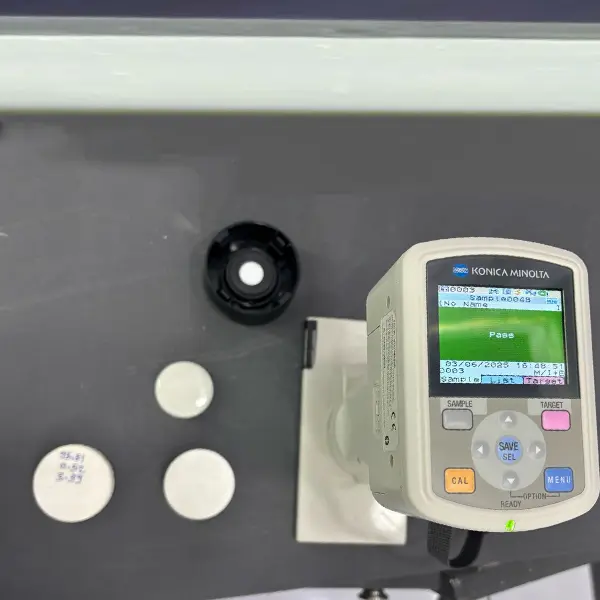

การประยุกต์ใช้สเปกโตรโฟโตมิเตอร์ที่สำคัญอีกประการหนึ่งในผลิตภัณฑ์เซรามิกสำเร็จรูปคือการควบคุมความสม่ำเสมอของชุดการผลิต ในการผลิตขนาดใหญ่ การรักษาสีให้มีความสม่ำเสมอตลอดการผลิตหลายๆครั้งถือเป็นสิ่งสำคัญ โดยเฉพาะอย่างยิ่งสำหรับเซรามิกที่ใช้ในงานสถาปัตยกรรมหรืออุตสาหกรรม สเปกโตรโฟโตมิเตอร์สามารถวิเคราะห์แบบผ่านหรือไม่ผ่านได้โดยการเปรียบเทียบข้อมูลสีที่วัดได้กับมาตรฐานหลัก ช่วยให้ผู้ผลิตสามารถพิจารณาได้อย่างรวดเร็วว่าผลิตภัณฑ์เป็นไปตามข้อกำหนดหรือไม่มีความคลาดเคลื่อนก่อนที่จะส่งมอบให้กับลูกค้า

โซลูชันการวัดสีของ Konica Minolta สำหรับผลิตภัณฑ์เซรามิก

Konica Minolta Sensing ซึ่งเป็นชื่อที่ได้รับความไว้วางใจในด้านโซลูชันการวัดสีในอุตสาหกรรมเซรามิก นำเสนอเครื่องวัดสเปกตรัมหลายประเภท ซึ่งช่วยให้วัดสีได้อย่างแม่นยำและควบคุมคุณภาพของวัตถุดิบเซรามิกและผลิตภัณฑ์สำเร็จรูป ทำให้การรับรองความสม่ำเสมอของสีและคุณภาพมีสม่ำเสมอมอ

เครื่องวัดค่าสเปกโตรโฟโตมิเตอร์ CM-26dG/CM-25d (ซ้าย) และเครื่องวัดค่าสเปกโตรโฟโตมิเตอร์ CM-17d (ขวา)

รุ่นที่โดดเด่นได้แก่เครื่องวัดค่าสเปกโตรโฟโตมิเตอร์ CM-25dซึ่งเป็นรุ่นต่อจากรุ่น CM-2500d ที่ได้รับความนิยมอย่างล้นหลาม และสเปกโตรโฟโตมิเตอร์ CM-17dทั้งสองรุ่นมาพร้อมกับโหมดการวัด SCI และ SCE และมอบความสามารถในการทำซ้ำได้สูงและIIA (ข้อตกลงระหว่างตราสาร)เพื่อให้แน่ใจว่าการวัดสีมีความแม่นยำและเชื่อถือได้สำหรับวัสดุและผลิตภัณฑ์เซรามิกต่างๆ อีกสิ่งหนึ่งที่ควรกล่าวถึงคือเครื่องวัดค่าสเปกโตรโฟโตมิเตอร์ CM-26dGซึ่งมาพร้อมกับเซ็นเซอร์วัดความเงา 60° ในตัวสำหรับการวัดสีและความเงาพร้อมกัน ทำให้เป็นเครื่องมืออเนกประสงค์สำหรับการควบคุมคุณภาพในอุตสาหกรรมเซรามิก ดูวิดีโอเพื่อเจาะลึกคุณสมบัติทั้งหมด

ชมวีดีโอ

หากต้องการความช่วยเหลือเกี่ยวกับการวัดสีของหรือค้นวิธีการความคุมคุณภาพของสีให้เหมาะสมสมกับโซลูชันการวัดสีเซรามิก สามารถติดต่อเราเพื่อรับคำปรึกษาฟรีโดยทีมผู้เชี่ยวชาญของเราจะช่วยให้คุณค้นหาโซลูชันที่เหมาะสมที่สุดสำหรับความต้องการเฉพาะของคุณ