ทำอย่างไรจึงจะได้สีลิปสติกและเฉดสีที่เหมาะสมอย่างสม่ำเสมอ

สีเป็นคุณลักษณะที่สำคัญของลิปสติก นอกจากการพัฒนาคอลเลกชั่นสีและเฉดสีที่เหมาะกับสีผิวประเภทต่างๆ แล้ว การทำให้แต่ละเฉดสีถูกต้องสม่ำเสมอก็มีความสำคัญไม่แพ้กันในการดึงดูดลูกค้าใหม่และรักษาลูกค้าปัจจุบัน

ลิปสติกโดยทั่วไปทำมาจากน้ำมัน แว็กซ์ และเม็ดสี– ในขั้นแรกให้ผสมน้ำมันและแว็กซ์เพื่อสร้างโครงสร้างพื้นฐานของลิปสติกเบส จากนั้น เม็ดสีจะถูกเติมลงในฐานที่ละลายแล้วผสมให้เข้ากันจนเป็นเนื้อลิปสติกขั้นสุดท้าย ส่วนผสมจะปั้นหรือเทลงในภาชนะและเก็บไว้สำหรับการปั้นในอนาคต เพื่อให้สีลิปสติกและเฉดสีมีความสม่ำเสมอตลอดกระบวนการผลิต การใช้เครื่องมือวัดสีจะมีความจำเป็นอย่างมาก

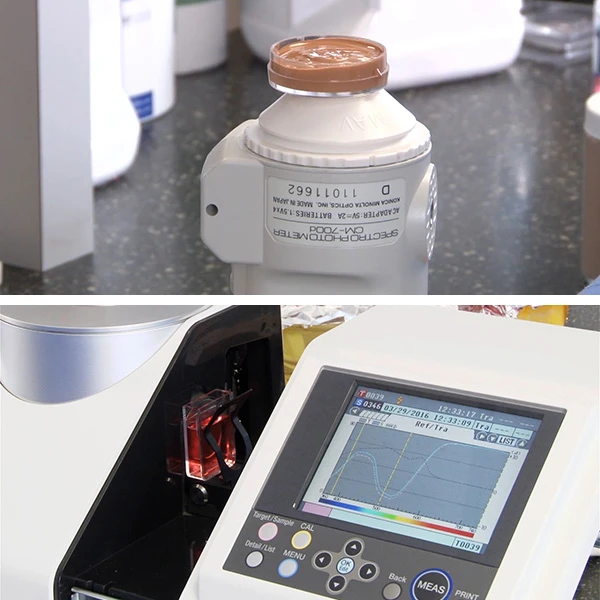

ขั้นตอนแรกสู่สีและเฉดลิปสติกที่แม่นยำและสม่ำเสมอคือการสร้างระยะของค่าสี– เม็ดสีซึ่งเป็นส่วนผสมหลักที่ทำให้ลิปสติกมีสี ควรตรวจสอบก่อนผสม เนื่องจากเม็ดสีมาในรูปแบบต่างๆ เช่น ผงหรือของเหลว จึงจำเป็นต้องใช้การวัดการสะท้อนแสงหรือการส่งผ่านตามระดับความโปร่งใสเพื่อให้แน่ใจว่ามีความแม่นยำและทำซ้ำๆได้ เพื่อจำลองว่าสีและเฉดสีจะมีลักษณะอย่างไรเมื่อทา ลิปสติกเนื้อครีมขั้นสุดท้ายสามารถทาบนแผนภูมิทดสอบขาวดำหรือการ์ดเลเนตาก่อนทำการวัด

เครื่องมือวัดสีเช่น Konica Minoltaสเปกโตรโฟโตมิเตอร์ CM-5ด้วยความอเนกประสงค์ของการวัดการสะท้อนแสงและการส่งผ่าน และสเปกโตรโฟโตมิเตอร์ CM-700dสามารถช่วยผู้ผลิตเครื่องสำอางวัดสีและเฉดสีของลิปสติกได้อย่างง่ายดาย ด้วยอุปกรณ์เสริมที่หลากหลาย เช่น ภาชนะในการใส่ตัวอย่าง ทั้ง CM-5 และ CM-700d จึงสามารถจัดการกับรูปแบบตัวอย่างที่หลากหลายตั้งแต่ของแข็งและผงไปจนถึงเนื้อครีมและของเหลว

มาร่วมเรียนรู้และทำความเข้าใจพื้นฐานของการวัดสีด้วยโปรแกรมฟรีของเราจากเอกสารนี้

และสามารถติดต่อเราเพื่อการสาธิตผลิตภัณฑ์หรือคำปรึกษาฟรีเกี่ยวกับวิธีที่คุณสามารถปรับปรุงกระบวนการจัดการสีหรือการเลือกเครื่องมือและวิธีการสำหรับความต้องการในการวัดของคุณ