การปรับปรุงการตรวจสอบคุณภาพอาหารด้วยการถ่ายภาพไฮเปอร์สเปกตรัม

สิ่งสำคัญประการหนึ่งสำหรับผู้ผลิตอาหารคือการรับประกันคุณภาพของผลิตภัณฑ์ของตน และเกี่ยวข้องกับการตรวจสอบอาหารในขั้นตอนต่างๆ ของการผลิตเพื่อให้แน่ใจว่าปราศจากการปนเปื้อนและการเจือปน หรือการปฏิบัติตามกฎหมาย ข้อบังคับ หลักปฏิบัติ และมาตรฐานสากลที่เกี่ยวข้อง มีวิธีการต่างๆ หลายวิธีที่ใช้ในการตรวจสอบอาหาร รวมถึงการตรวจสอบด้วยสายตา การวิเคราะห์ในห้องปฏิบัติการ และวิชันซิสเต็ม

การตรวจสอบด้วยสายตาเป็นวิธีการทั่วไปและเป็นพื้นฐานที่สุดในการตรวจสอบคุณภาพอาหาร ผู้ตรวจสอบใช้ภาพชี้นำเช่นสีเนื้อสัมผัสและรูปลักษณ์เพื่อประเมินคุณภาพและความปลอดภัยของอาหาร การวิเคราะห์ในห้องปฏิบัติการมักใช้ร่วมกับการตรวจพินิจเพื่อสนับสนุนหรือยืนยันการประเมิน การทดสอบในห้องปฏิบัติการทั่วไป ได้แก่ การทดสอบจุลินทรีย์ ซึ่งใช้เพื่อตรวจจับการมีอยู่ของจุลินทรีย์ที่เป็นอันตรายในผลิตภัณฑ์อาหาร หรือการวิเคราะห์ทางเคมีเพื่อช่วยระบุการมีอยู่ของสารเคมีอันตรายในผลิตภัณฑ์อาหาร อย่างไรก็ตาม วิธีการดังกล่าวเป็นเรื่องที่น่าเบื่อ ลำบาก ใช้เวลามาก และขาดความเป็นกลางและความรวดเร็วสำหรับการผลิตอาหารที่มีปริมาณสูงและความเร็วสูงในปัจจุบัน

วิชันซิสเต็มสำหรับการตรวจสอบอาหาร

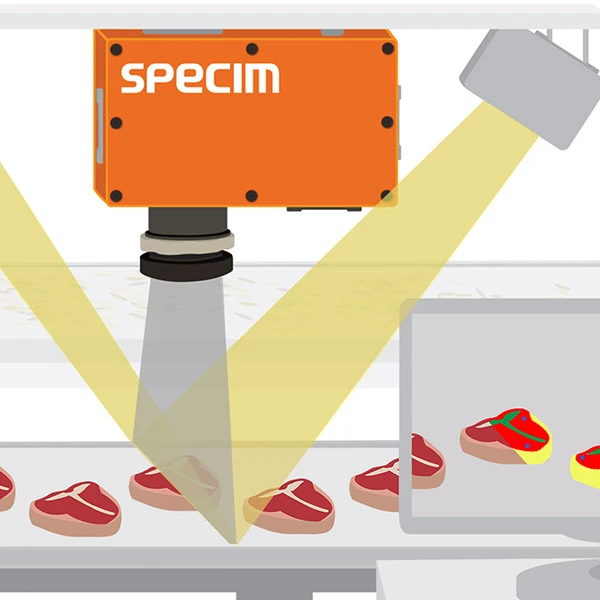

ด้วยปริมาณการผลิตที่เพิ่มขึ้นและความทนทานต่อคุณภาพที่เข้มงวดมากขึ้น หลายๆ คนจึงหันมาใช้ระบบวิชันซิสเต็มสำหรับการตรวจสอบคุณภาพของอาหาร ระบบวิชันซิสเต็มแบบทั่วไปได้รับการกำหนดค่าโดยใช้กล้องหรือเซ็นเซอร์ RGB (แดง เขียว และน้ำเงิน) เพื่อระบุลักษณะอาหารตามสี อย่างไรก็ตาม ความสามารถในการระบุตัวตนมีจำกัดเนื่องจากใช้แถบสีเพียงสามแถบเท่านั้น ในช่วงไม่กี่ปีที่ผ่านมามีความก้าวหน้าอย่างมากในการพัฒนาเทคโนโลยีวิชันซิสเต็มใหม่สำหรับการตรวจสอบคุณภาพอาหารการถ่ายภาพไฮเปอร์สเปกตรัม (HSI) แตกต่างจากกล้อง RGB ที่ใช้แถบที่มองเห็นเพียงสามแถบเท่านั้นกล้องไฮเปอร์สเปกตรัมใช้คลื่นความถี่ที่ต่อเนื่องกันนับแสนคลื่น ไม่จำกัดเพียงส่วนที่มองเห็นได้ ดังนั้นจึงสามารถให้ข้อมูลรายละเอียดจำนวนมากซึ่งสามารถใช้ในการระบุและจัดเรียงอาหารตามองค์ประกอบทางเคมี ไม่ใช่แค่สีเท่านั้น วัสดุทุกชนิดมีองค์ประกอบที่เป็นเอกลักษณ์และทำปฏิกิริยาแตกต่างกันไปในช่วงความยาวคลื่นที่แตกต่างกัน เช่น ปริมาณแสงที่สะท้อน ปล่อยออกมา หรือส่งผ่าน กล้องไฮเปอร์สเปกตรัมจับปฏิกิริยาเหล่านี้และใช้เป็นลายเซ็นสเปกตรัม เช่น ลายนิ้วมือของเรา เพื่อระบุตัวตน

แยกแยะวอลนัทออกจากเปลือกด้วยการถ่ายภาพไฮเปอร์สเปกตรัม.

ได้รับความอนุเคราะห์จาก SPECIM, SPECTRAL IMAGING LTD

กล้องถ่ายภาพไฮเปอร์สเปกตรัม

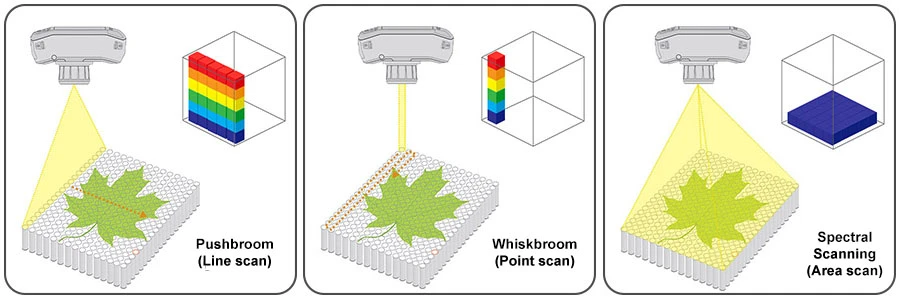

กล้องไฮเปอร์สเปกตรัมมีหลายประเภทเช่น สแกนเส้น สแกนจุด สแกนสเปกตรัม ฯลฯ และแต่ละวิธีก็มีวิธีการจับข้อมูลไฮเปอร์สเปกตรัมเป็นของตัวเอง กล้องไฮเปอร์สเปกตรัม Pushbroom ทำงานโดยการกวาดผ่านเป้าหมาย จากบรรทัดพิกเซลหนึ่งไปยังอีกบรรทัดหนึ่ง เพื่อสร้างข้อมูลไฮเปอร์สเปกตรัมกล้องไฮเปอร์สเปกตรัมของ Whiskbroom จับภาพได้ครั้งละหนึ่งพิกเซล พวกเขาสร้างดาต้าคิวบ์ไฮเปอร์สเปกตรัมผ่านการเป้าหมาย กล้องไฮเปอร์สเปกตรัมที่ใช้การสแกนสเปกตรัมจะสร้างคิวบ์ข้อมูลไฮเปอร์สเปกตรัมโดยการวัดแถบความยาวคลื่นทีละแถบ เนื่องจากอาหารมักจะเคลื่อนที่ไปตามสายการผลิตหรือสายการผลิต กล้องไฮเปอร์สเปกตรัมแบบ pushbroom จึงเหมาะอย่างยิ่งในการตรวจสอบอาหารที่เคลื่อนไหว

ตัวอย่างที่แสดงให้เห็นว่ากล้องไฮเปอร์สเปกตรัม (ซ้าย) ไม้กวาด (กลาง) และการสแกนสเปกตรัม (ขวา) จับภาพข้อมูลไฮเปอร์สเปกตรัมได้อย่างไร

กล้องไฮเปอร์สเปกตรัมจำเพาะ

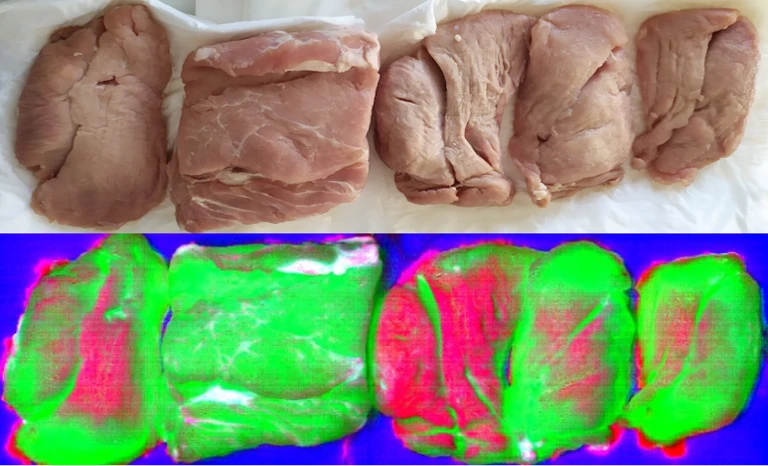

Specim ผู้บุกเบิกและผู้นำด้านเทคโนโลยี HSI นำเสนอกล้องไฮเปอร์สเปกตรัมแบบไม้กวาดหลายรุ่นที่ครอบคลุมคุณสมบัติต่างๆ ที่บริเวณสเปกตรัมจาก VNIR (มองเห็นและอินฟราเรดใกล้) ถึง LWIR (อินฟราเรดคลื่นยาว) เหล่านี้ได้แก่กล้องไฮเปอร์สเปกตรัมแบบมือถือ, กล้องไฮเปอร์สเปกตรัมทางอุตสาหกรรม, ระบบ HSI การตรวจจับทางอากาศและระยะไกล ฯลฯ เมื่อพูดถึงการตรวจสอบคุณภาพอาหารSpecim FX ซีรี่ส์โดยเฉพาะกล้องไฮเปอร์สเปกตรัม FX10 และ FX17 มีอัตราเฟรมสูงที่ตรงกับความเร็วของสายการผลิตหรือกระบวนการแปรรูปอาหารหลายเมตรต่อวินาที ช่วยให้ตรวจสอบได้อย่างแม่นยำในการผลิตอาหารความเร็วสูงในปัจจุบัน ด้วยแถบสเปกตรัม 224 แถบและความละเอียดเชิงพื้นที่สูง FX10 ซึ่งครอบคลุมบริเวณสเปกตรัม VNIR และ FX17 ในบริเวณสเปกตรัม NIR (ใกล้อินฟราเรด) สามารถระบุอาหารได้อย่างน่าเชื่อถือตามเนื้อหาทางกายภาพ ชีวภาพ และเคมี ช่วยให้ตรวจสอบได้ง่าย และคัดเกรดอาหารรวมถึงการตรวจหาวัตถุแปลกปลอมและสิ่งปนเปื้อน

กล้องไฮเปอร์สเปกตรัม Specim FX ซีรีส์ใช้ในงานตรวจสอบอาหารหลายประเภท เช่นเนื้อ–ถั่ว–ผลไม้ และ ผักฯลฯ วิดีโอเพื่อดูข้อมูลเพิ่มเติมเกี่ยวกับกล้องไฮเปอร์สเปกตรัม Specim FX ซีรีส์

การระบุข้อบกพร่องต่างๆ จากตัวอย่างเนื้อสัตว์ด้วยกล้องไฮเปอร์สเปกตรัม Specim FX17.

ได้รับความอนุเคราะห์จาก SPECIM, SPECTRAL IMAGING LTD

หากต้องการความช่วยเหลือในการค้นหากล้องไฮเปอร์สเปกตรัมและโซลูชันที่เหมาะสมสำหรับการใช้งานด้านอาหาร สามารถติดต่อผู้เชี่ยวชาญของเราเพื่อรับคำปรึกษาฟรี