การทดสอบการแสดงผลแบบ Pillar-to-Pillar (P2P)

วิวัฒนาการทางเทคโนโลยีของแผงจอแสดงผลนั้นรวดเร็วมาก โดยมีความก้าวหน้าใหม่ๆ ที่เปลี่ยนแปลงวิธีการที่เราโต้ตอบกับหน้าจอในแทบทุกส่วน ตั้งแต่อุปกรณ์อิเล็กทรอนิกส์เพื่อการบริโภคถึงยานยนต์การพัฒนาที่สร้างสรรค์อย่างหนึ่งในช่วงไม่กี่ปีที่ผ่านมา โดยเฉพาะในอุตสาหกรรมยานยนต์ คือ การเพิ่มขึ้นของจอภาพแบบ Pillar-to-Pillar (P2P) ซึ่งประกอบด้วยแผงจอภาพหลายแผงที่ครอบคลุมความกว้างทั้งหมดของแผงหน้าปัดรถยนต์ ตั้งแต่เสา A หนึ่งไปยังอีกเสาหนึ่ง โดยแผงเหล่านี้ผสานรวมข้อมูลสำคัญ เช่น ระบบนำทาง ระบบความบันเทิง และแม้แต่ในรูปแบบความจริงเสริม (AR)ในองค์ประกอบต่างๆ ให้เป็นอินเทอร์เฟซที่ไร้รอยต่อ เนื่องจากผู้ผลิตรถยนต์จำนวนมากเลือกใช้จอแสดงผลแบบจอกว้างแบบรวมศูนย์ที่ให้รูปลักษณ์ทันสมัยและฟังก์ชันการทำงานที่ได้รับการปรับปรุง ความต้องการวิธีการตรวจสอบภาพที่แม่นยำจึงไม่เคยสูงเท่านี้มาก่อน

ความท้าทายในการตรวจสอบการแสดงผลแบบ Pillar-to-Pillar (P2P)

พารามิเตอร์มาตรฐาน เช่น ความสว่าง ความเข้มของสีความสม่ำเสมอและข้อบกพร่องของพิกเซลมีความสำคัญอย่างยิ่งต่อการรับประกันประสิทธิภาพที่ดีที่สุดของจอภาพแบบ Pillar-to-Pillar (P2P) อย่างไรก็ตาม การกำหนดค่าเฉพาะและขนาดที่ใหญ่กว่าของจอภาพเหล่านี้สร้างความท้าทายในการทดสอบที่เกินกว่าจอภาพแบบจอแบนทั่วไปหรือขนาดมาตรฐานสำหรับรถยนต์

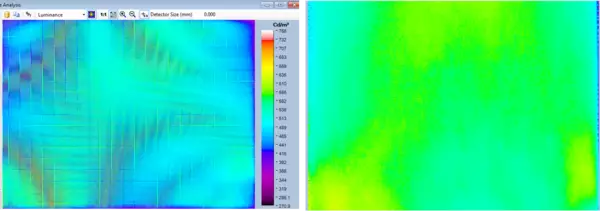

จอแสดงผลแบบ Pillar-to-Pillar (P2P) จำนวนมากมีการออกแบบโค้ง ทำให้การทดสอบจอแสดงผลมีความซับซ้อนมากขึ้น โดยเฉพาะการลบมูเร่ มูเร่เป็นอาตีแฟกต์ภาพที่ไม่พึงประสงค์ หรือรูปแบบหนึ่งของการสร้างภาพซ้อน ซึ่งมักพบเห็นได้เมื่อถ่ายภาพหน้าจอแสดงผล หากปล่อยทิ้งไว้โดยไม่ได้รับการแก้ไข อาจทำให้การตรวจจับข้อบกพร่องของพิกเซลไม่ชัดเจน แม้ว่าซอฟต์แวร์ทดสอบจอแสดงผลส่วนใหญ่จะมีอัลกอริธึมในกการลบมูเร่ที่มีประสิทธิภาพบนพื้นผิวเรียบ แต่ความโค้งของจอแสดงผลแบบ Pillar-to-Pillar (P2P) อาจทำให้เกิดการเปลี่ยนแปลงของโฟกัสได้ ทำให้ประสิทธิภาพของอัลกอริธึมในการตรวจจับข้อบกพร่องของพิกเซลลดความแม่นยำลง การแก้ไขปัญหาเหล่านี้ต้องใช้ระบบถ่ายภาพความละเอียดสูงที่มีรูรับแสงที่ปรับเทียบแล้วที่ f/8 หรือสูงกว่า การตั้งค่านี้ช่วยให้ได้ระยะชัดลึกที่มากขึ้น ทำให้โฟกัสได้สม่ำเสมอมากขึ้นทั่วทั้งจอแสดงผลแบบโค้ง

ตัวอย่างก่อน (ซ้าย) และหลัง (ขวา) การลบมัวเร

ภาพโดย Radiant Vision Systems, LLC

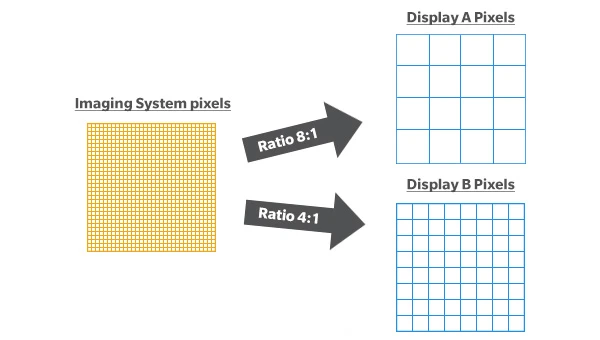

นอกจากความท้าทายด้านความโค้งแล้ว การแสดงผลแบบ P2P (Pillar-to-Pillar) ขนาดกว้างยังทำให้เกิดความยากลำบากในการวัดระดับพิกเซล การรักษาความโค้งที่เหมาะสมอัตราส่วนการโอเวอร์แซมปลิงพิกเซลระหว่างพิกเซลของเซนเซอร์ระบบถ่ายภาพและพิกเซลของจอแสดงผลนั้นมีความสำคัญอย่างยิ่งในการจับภาพข้อมูลพิกเซลและตรวจจับข้อบกพร่องของพิกเซลได้อย่างแม่นยำ วิธีหนึ่งคือจับภาพส่วนต่างๆ ของจอแสดงผลหลายๆ ส่วนแล้วจึงรวมภาพเข้าด้วยกัน อย่างไรก็ตาม มักจะใช้เวลานานที่จะตอบสนองข้อกำหนดเวลาในกระบวนการผลิตจำนวนมาก วิธีแก้ปัญหาที่มีประสิทธิภาพมากกว่าคือการใช้ระบบถ่ายภาพความละเอียดสูง โดยควรใช้ความละเอียด 45 ล้านพิกเซลขึ้นไป ระบบนี้สามารถจับภาพทั้งจอแสดงผลในภาพเดียวในขณะที่ยังคงอัตราส่วนลดจำนวนตัวอย่างที่จำเป็นไว้ ทำให้มั่นใจได้ถึงความเร็วและความแม่นยำในกระบวนการวัด

ตัวอย่างประกอบของพิกเซลเซนเซอร์ของระบบถ่ายภาพเทียบกับพิกเซลจอแสดงผล

นอกจากนี้ จอแสดงผลแบบ Pillar-to-Pillar (P2P) จำนวนมากในปัจจุบันได้นำเทคโนโลยีจอแสดงผลแบบเปล่งแสงมาใช้ เช่นโอแอลอีดี–ไมโครแอลอีดีและ miniLED สำหรับคุณภาพภาพที่เหนือกว่าและความยืดหยุ่น จอแสดงผลแบบเปล่งแสงเหล่านี้ต้องได้รับการทดสอบอย่างระมัดระวังเพื่อให้แน่ใจว่าแสงมีความสม่ำเสมอทั่วทั้งพื้นผิว เราแนะนำให้ใช้ระบบถ่ายภาพความละเอียดสูง เช่น ระบบที่มีพิกเซล 61 ล้านพิกเซลขึ้นไป ร่วมกับซอฟต์แวร์แบบครบวงจร เพื่อการวัดพิกเซลและพิกเซลเล็กๆที่มีความแม่นยำ จึงสามารถคำนวณปัจจัยการปรับและนำไปใช้เพื่อแก้ไข (เดดมูระ) การแสดงผลเพื่อให้มั่นใจถึงประสิทธิภาพที่สม่ำเสมอทั่วทั้งพื้นผิว

โซลูชันการวัดสำหรับการแสดงผลแบบ Pillar-to-Pillar (P2P)

Radiant Vision Systems ซึ่งเป็นส่วนหนึ่งของ Konica Minolta Group นำเสนอโซลูชันการทดสอบจอแสดงผลที่ครอบคลุมซึ่งออกแบบมาสำหรับการตรวจสอบการผลิตความเร็วสูง สำหรับการทดสอบจอแสดงผลแบบ Pillar-to-Pillar (P2P) พวกเรานำเสนอระบบที่ใช้การวัดสีภาพขั้นสูงซึ่งรวมถึงเครื่องวัดค่าสี ProMetric® I seriesและซอฟต์แวร์ TrueTest™–

เครื่องวัดค่าสี ProMetric® I ซีรีส์ มีตัวเลือกความละเอียดสูงถึง 61 ล้านพิกเซล และมาพร้อมกับเลนส์ควบคุมด้วยระบบอิเล็กทรอนิกส์ที่ได้รับการปรับเทียบจากโรงงาน ซึ่งให้ความยืดหยุ่นสำหรับระยะการทำงานและการตั้งค่ารูรับแสงที่แตกต่างกัน (เช่น f/3.3, f/8) นอกจากนี้ ยังรองรับอุปกรณ์เสริม เช่นเลนส์กล้องส่องคอสำหรับประสิทธิภาพการรับชมและเลนส์กล้องจุลทรรศน์สำหรับการประเมินโครงสร้างพิกเซล เมื่อใช้ร่วมกับซอฟต์แวร์ TrueTest™ แบบครบวงจร ซึ่งรวมถึงโมดูลเสริม เครื่องวัดค่าสีภาพสามารถวัดค่าพารามิเตอร์ต่างๆ ได้มากมายในจอแสดงผลแบบ Pillar-to-Pillar (P2P) พารามิเตอร์เหล่านี้ได้แก่ ความสว่าง สีสัน ความคมชัดมุมมอง–ประกายแสง การสอบเทียบความสม่ำเสมอ (เดดมูระ) การวัดในระดับย่อยพิกเซล และข้อบกพร่องของเส้นและพิกเซล

เครื่องวัดค่าสีแบบถ่ายภาพ ProMetric® ซีรีส์ I พร้อมเลนส์โคโนสโคป (ซ้าย) และเลนส์กล้องจุลทรรศน์ (ขวา)

ภาพจาก Radiant Vision Systems, LLC

หากสนใจที่จะเรียนรู้เพิ่มเติมเกี่ยวกับระบบถ่ายภาพ Radiant Vision Systems สำหรับการแสดงผลแบบ Pillar-to-Pillar (P2P) หรืออาจต้องการความช่วยเหลือในการค้นหาวิธีการวัดที่เหมาะสมสำหรับการทดสอบการแสดงผลของคุณ สามารถติดต่อทีมผู้เชี่ยวชาญของเราเพื่อรับคำปรึกษาฟรี