KONICA MINOLTA BENCHTOP SPECTROPHOTOMETER CM-36dG SERIES

For High-Accuracy Color Management and Digital Transformation Of Global Supply Chain

Singapore, 14th January 2021

Konica Minolta Sensing Singapore Pte Ltd is pleased to announce the launch of the new benchtop spectrophotometer CM-36dG series in February 2021.

The new series includes the horizontal-format Spectrophotometer CM-36dG and vertical-format Spectrophotometer CM-36dGV, both of which offer simultaneous measurement of color and gloss, and the entry-level model Spectrophotometer CM-36d for reflectance color measurements.

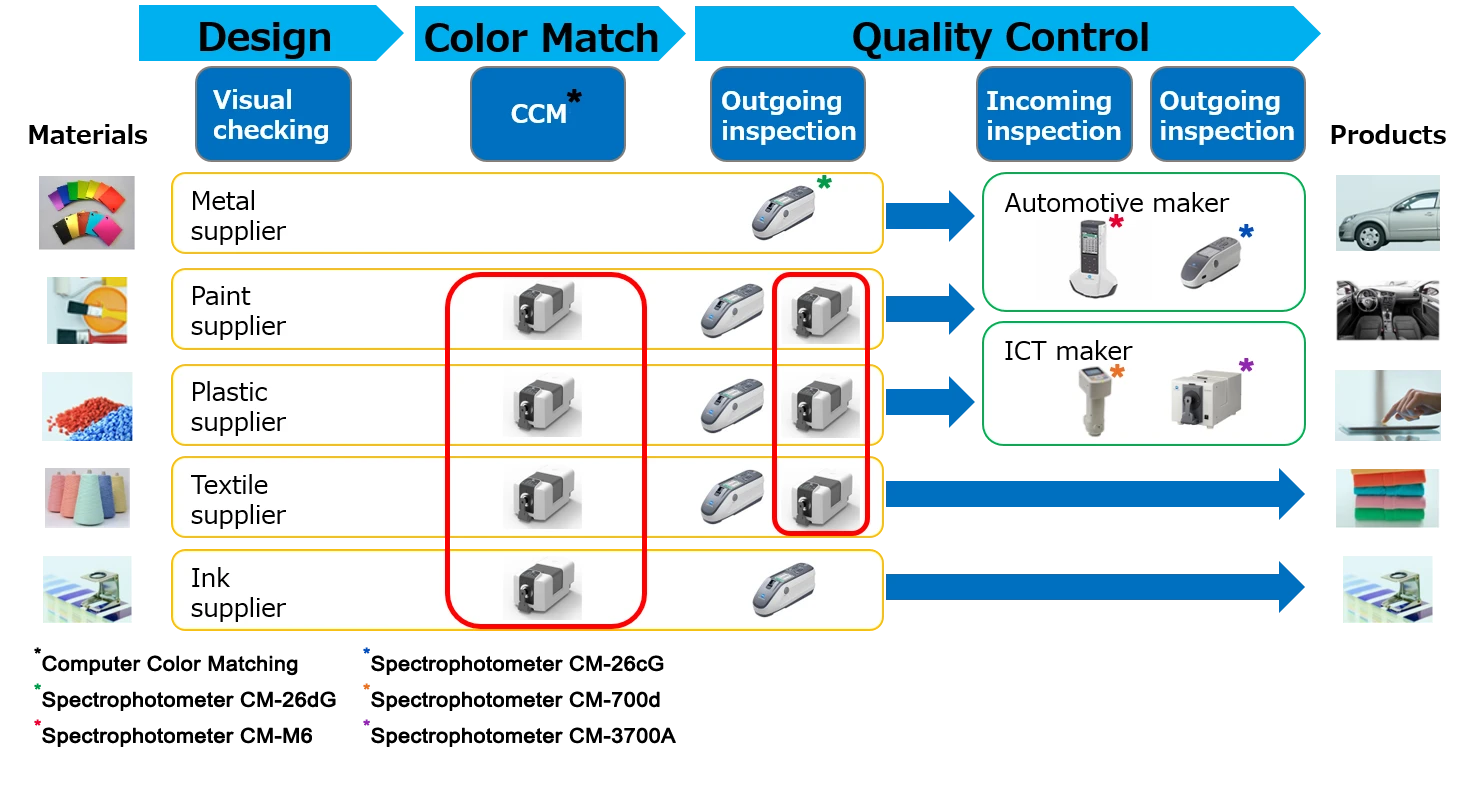

Successor to the benchtop Spectrophotometers CM-3600A and CM-3610A that are widely used by material suppliers in the automotive and IT equipment fields, the new Spectrophotometer CM-36dG series is ideal for color-matching and quality control applications for paint, plastic, textile, etc., and material suppliers. The new CM-36dG series offers simultaneous measurement of color and gloss*1 for inspection processes efficiency and high measurement accuracy for outstanding quality control.

The new CM-36dG series offers high stability and reliability with the WAA (Wavelength Analysis & Adjustment) function that compensates for slight shifts in measured values due to external influences like ambient temperature changes. Measurement operation usability has also significantly improved to help increase operator productivity.

With the coronavirus and the globalization of supply chains, digitalization in production areas is accelerating. The new Spectrophotometer CM-36dG series can convert color and gloss information into digital data with high accuracy, enabling the digital transformation (DX) of manufacturing by realizing quality control without relying on target samples or the eyes of skilled workers.

*1 Spectrophotometer CM-36dG and CM-36dGV only

Simultaneous Measurement Of Color And Gloss For Improved Inspection Processes Efficiency

The CM-36dG and CM-36dGV are both two-in-one spectrophotometers that offers simultaneous color and gloss measurement. For color matching of paint, measuring both color (spectral reflectance) and gloss increases the parameters for color-matching calculations and help improve quality. For quality control of plastics, high-level quality evaluation and improved work efficiency can be achieved by measuring both the color (material color) and the gloss (surface conditions).

High Measurement Accuracy For Excellent Quality Control

Both the Spectrophotometer CM-36dG and Spectrophotometer CM-36dGV offers extremely tight inter-instrument agreement. The colorimetric inter-instrument agreement for both instruments are within ΔE*ab 0.12 (average for 12 BCRA tiles), a 20% improvement compared to their predecessor, with their gloss inter-instrument agreement matches or better the performance of gloss-only instruments.

With such tight inter-instrument agreement, exceedingly small differences in measurement data between instruments can be expected. It enables a more consistent measurement result, efficiently, within the supply chain, from suppliers to finished product maker, when using multiple instruments or instruments in several locations.

Additionally, measurement data differences against their predecessor are also kept exceedingly small. Older data from their predecessor can continue to be used as it is, minimizing the work needed when switching models (for SCI data only*2).

*2 SCI: Specular Component Included. An illumination/viewing method in which the sample is diffusely illuminated, and the measured light includes specularly reflected light.

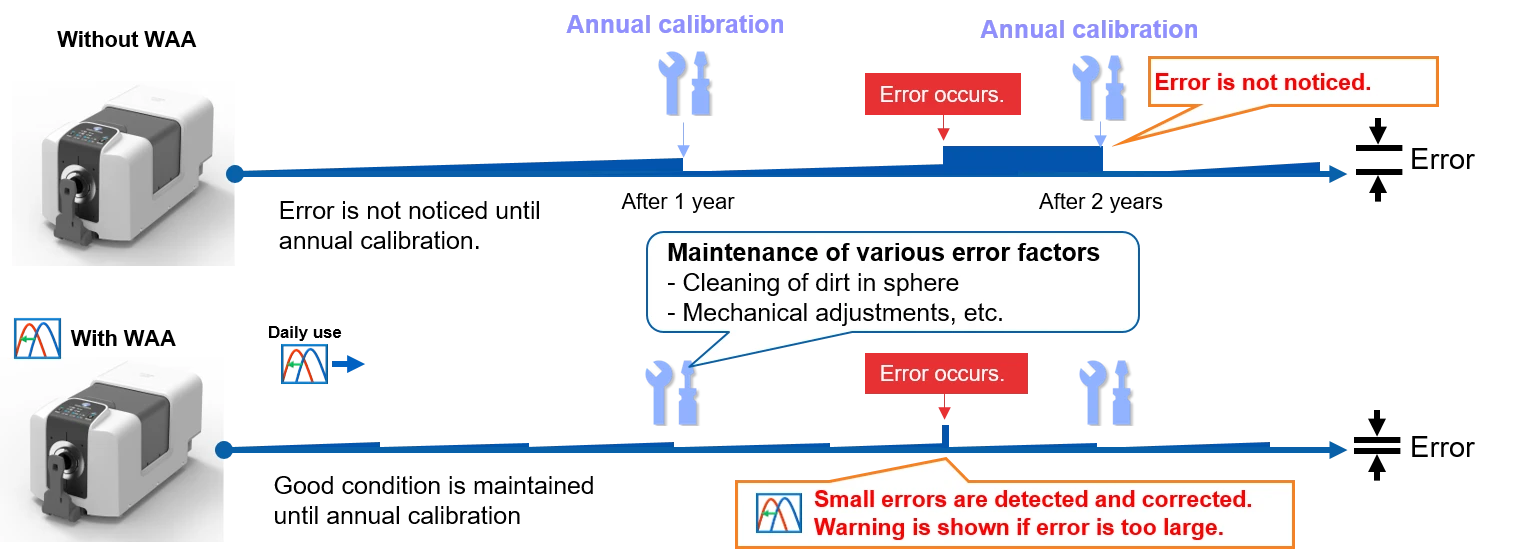

High Stability Through Wavelength Compensation Function

The WAA*3 function compensates for slight shifts in measurement data due to external factors (e.g., ambient temperature changes, etc.). Together with annual calibration and maintenance, stable operation, with minimum problems, can be expected.

General Concept of WAA

*3 WAA license required

High Usability For Improved Operator Productivity

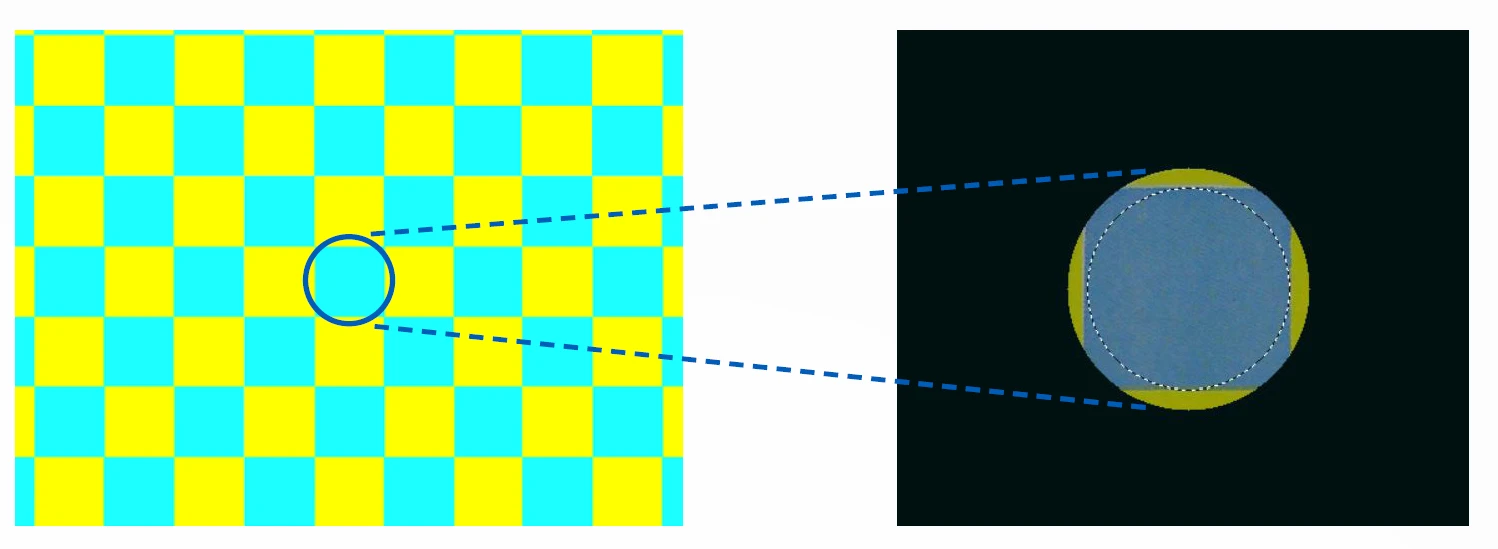

The new Spectrophotometer 36dG series comes with the sample viewing function*4. It uses an integrated camera that provides a view of the sample within the integrating sphere, allowing accurate and easy positioning of the measurement sample.

The CM-36dG series features a status panel that displays both the measurement status and condition settings to help minimize operator error. The measuring button is also located at the status panel for improved work efficiency, allowing the operator to take measurements without switching back to the computer.

Also, the 36dG series comes with a large and wide transmittance chamber that allows easy measurements of large sheets or panels without needing to cut them. 4 different measurement areas (3 different measurement areas for Spectrophotometer CM-36d) are available to provide flexibility for different measurement needs.

*4 Konica Minolta SpectraMagic NX software Ver. 3.2 or later required.

Application Concept

Main Specifications*5

| Model | CM-36dG | CM-36dGV | CM-36d | |

| Color | Illumination/viewing system | di: 8°, de: 8° (diffused illumination, 8° viewing angle), SCI (specular component included)/SCE (specular component excluded) switchable

Conforms to DIN 5033 Teil7, JIS Z 8722 Condition “c”, ISO7724/1, CIE No.15(2004)、ASTM E1164 for reflectance measurements |

||

| Measurement/

Illumination area |

LAV: Ø25.4mm/Ø30mm

LMAV: Ø16mm/Ø20mm MAV: Ø8mm/Ø11mm SAV: Ø4mm/Ø7mm |

LAV: Ø25.4mm/Ø30mm

MAV Ø8mm/Ø11mm SAV: Ø4mm/Ø7mm |

||

| Repeatability | “Colorimetric values:Standard deviation within ΔE*ab 0.02

(When a white calibration plate is measured 30 times at 10-second intervals after white calibration under Konica Minolta standard measurement conditions) |

Colorimetric values:Standard deviation within ΔE*ab 0.03 (When a white calibration plate is measured 30 times at 10-second intervals after white calibration under Konica Minolta standard measurement conditions) |

||

| Inter-instrument agreement |

Within ΔE*ab 0.12

(Based on average for 12 BCRA Series II color tiles; LAV/SCI. Compared to values measured with a master body under Konica Minolta standard measurement conditions) |

Within ΔE*ab 0.15

(Based on average for 12 BCRA Series II color tiles; LAV/SCI. Compared to values measured with a master body under Konica Minolta standard measurement conditions) |

||

| Transmittance measurement | Possible(Measurement area: Ø17mm) | |||

| UV setting | 100% / 0% / Adjusted (Instantaneous numerical adjustment of UV with no mechanical filter movement required)*6; 400 nm and 420 nm UV cutoff filters |

No adjustment function (UV100%) | ||

| Gloss | Measurement angle | 60° | ||

| Measurement area | MAV: 10 × 8 mm ellipse / SAV: Ø3 mm | |||

| Repeatability | Standard deviation within

0-10GU: 0.1 GU 10-100GU: 0.2GU 100-200GU: 0.2% of displayed value |

|||

| Inter-instrument agreement | 0-10GU: ±0.2GU

10-100GU: ±0.5GU |

|||

| Size(W×H×D) | Approx. 248×250×498 mm | Approx. 300×677×315 mm | Approx. 248×250×498 mm | |

| Weight | Approx. 8.4 kg | Approx.14.0 kg | Approx.8.3kg | |

*5 The information, specifications, and product appearance provided in this news release are subject to change without notice.

*6 Numerical adjustment of UV requires UV Adjustment Software (included with optional Konica Minolta SpectraMagic NX Pro Ver. 3.2 or later)

About Konica Minolta Sensing Singapore Pte Ltd

Konica Minolta Sensing Singapore Pte Ltd, a wholly-owned subsidiary of Konica Minolta Inc, is a leading provider of industrial color and light measurement solutions. Konica Minolta Sensing Singapore serves the industry in more than 14 countries in the Asia-Pacific region with qualified Distributors.

Konica Minolta’s Sensing Business offers various products and solutions in the fields of light source color measurement and object color measurement based on the optical technologies developed in its former camera business and continually refined thereafter. The products and solutions offered by Konica Minolta contribute to the quality and productivity at the customers’ manufacturing sites, with many color measurement instruments being used as de-facto standards. Notably, Konica Minolta has more than 50% share in the global market for display image quality measurement and inspection (estimated by Konica Minolta) and has a solid presence as the market leader.

Konica Minolta has actively promoted investments to strengthen its competitiveness. In 2012, the company acquired Instrument Systems GmbH (Germany) which develops high-end optical measuring instruments and has an outstanding track record in the high-performance measurement of displays and LED lighting devices. In 2015, the company acquired Radiant Vision Systems, LLC (U.S.) which excels at high-resolution 2D measurement instruments for displays, image processing software, and automatic appearance inspection systems. In 2019, the company acquired Eines Systems (Spain), a market leader in the field of visual inspection of automobiles. Most recently, the company acquired Specim, Spectral Imaging Ltd. (Finland), a leading company in the field of hyperspectral imaging (HSI*7).

Konica Minolta remains committed to developing its measuring instrument business as a market leader with high value-added products and solutions that enable high-precision measurement of light and color for the ever-growing ICT, automobile, and materials supplier fields. The company strives to continue providing new customer value that surpasses the human eye in the areas of “safety,” “security,” and “hygiene” to contribute to the solution of global social issues.

*7 HSI is a method that uses a camera with narrow bandwidth over a wide spectral range from the visible to mid-infrared wavelength region to identify substances in an area. It is expected to be used for applications such as recycling, material/resource identification, food analysis, environmental safety, product surface condition analysis, etc.

Ng Wei Hua

Konica Minolta Sensing Singapore Pte Ltd

+65 6563 5533

weihua.ng@konicaminolta.com

Konica Minolta is a registered trademark of Konica Minolta, Inc. All other trademarks mentioned in this document are the property of their respective owners.