Symbol Industries, a subsidiary of the Diamond Group of Industries, shares its success in tackling color variation challenges in the production of SPS and polyurethane (PU) foam. By integrating the Color Reader CR-10 Plus into their operations, they achieved improvements in color accuracy, quality control, and production consistency.

This reliable and user-friendly color measurement instrument streamlined their workflow, minimized rework, and ensured compliance with strict customer standards. Supported by exceptional technical service, the CR-10 Plus became an indispensable asset in their quality control.

Accelerate your manufacturing process with Konica Minolta Sensing. In the competitive world of modern manufacturing, automation is crucial to increase efficiency, precision, and scalability. Our advanced color and light measurement instruments are designed to integrate seamlessly into automated workflows.

Tailored to fit your needs, our unique approach combines hardware integration with custom software, providing an adaptive extension to your system, enabling automated measurement tasks, traceable data collection, and in-depth analysis.

Introducing the Konica Minolta Spectrophotometer CM-17d, the latest portable spectrophotometer designed for effortless color measurements. As the successor to the CM-700d, it features an ergonomic, vertically-oriented design for easy one-handed use and maximum portability. The CM-17d includes an integrated camera viewfinder for simplified target alignment, switchable measurement apertures of 3mm and 8mm for versatility across various samples, and an optional vertical leveling jig for stable measurements. It also offers two tripod mounting threads for integration with cobots, robots, or automated systems.

Measuring metallic and pearlescent colors can be challenging due to their complex composition and light-reflecting properties. To address this, Konica Minolta has created the Multi-Angle Spectrophotometer CM-M6, which offers accurate measurements through six aspecular viewing angles and a patented double-path illumination system that ensures stability even on non-flat surfaces. With a Ø6 mm measuring area, it is ideal for small or curved parts, and its Bluetooth connectivity allows for easy data transfer and integration with other devices. The CM-M6’s compatibility with robotic arms further supports manufacturers in enhancing their color measurement processes in the context of Industry 4.0.

Color measurement has never been simpler with the CM-5 advanced all-in-one spectrophotometer. With its innovative operation, it enables anyone to take measurements easily anytime even without the use of a computer. The keyboard, color LCD screen, top-port design and automatic calibration make it extremely user friendly and popular in the chemical, food & beverages, pharmaceutical and packaging industries.

What’s more is the versatility of the CM-5, enabling a variety of samples with different material characteristics such as liquids, powders, pastes, and granules, as well as the haze of transparent films and glass to be measured.

Konica Minolta Spectrophotometer CM-36dG offers simultaneous measurement of color and gloss for workflow efficiency. With advanced functions and maximum flexibility for today’s measurement needs, it is suitable for various color-matching and quality control applications like paint, plastic, textile, etc., and material suppliers.

Spectrophotometer CM-26dG Series were developed for true Digital Color Data Management and are ideal for automotive interior and smartphones and tablets exterior color evaluation.

Konica Minolta Chroma Meter CR-400 and CR-410 Series are portable color measuring instruments that can be used in many types of applications, including food and plastics. With a wide selection of accessories, the CR-400 and CR-410 can handle samples in various forms, including powder, pastes, and opaque liquid.

SpectraMagic NX (SMNX) software is a simple and complete quality control solution for the measurement and analysis of color. This powerful software can be used in any industry, from plastic, paint & coating, and food to cosmetics, pharmaceuticals, chemicals, etc.

Used together with Konica Minolta Spectrophotometers, users can perform a comprehensive color measurement and analysis of incoming raw materials, in-process production, and outbound materials and goods with ease.

Color is an important element in the cosmetics industry, whether it’s to meet quality standards, enhance the appearance of a product, or evaluate how the human skin reacts to makeup. Color evaluation for cosmetics products generally is tested in appearance and also in application. Cosmetic products must appear good in color on the shelves and also when applied by the user.

Cosmetics, from raw material to final product, come in various forms and textures. It can be challenging for cosmetic manufacturers to ensure the color quality of their products. Konica Minolta offers various color measurement solutions and color management software that is suitable for quality inspection in production or routine and research measurements in the laboratory.

Color communicates freshness, flavor, and quality. Customer often evaluates foods based on their colors and associate these colors to certain tastes. It is, therefore, important to ensure the color is right and consistent through objective and repeatable measurement methods from raw materials and ingredients, down to the final product.

Color is one of the important elements of a soaps. It is used to reflect the identity of scent and help manufacturers identify issues with their soaps or production method. From raw material to final product, solid and opaque to liquid and translucent, Konica Minolta Spectrophotometer CM-5 and SpectraMagic NX Software offered simple and fast quality inspection and routine/research measurements of soaps color in the production or laboratory.

For routine grading of liquid chemical products that are clear or slightly yellow tinted, APHA Color, also called Hazen or Platinum Cobalt (Pt-Co) scale, is commonly used. The APHA color is a single-number color scale ranging from 0 (achromatic clear) to 500 (light yellow). The APHA color scale relies on visual comparison against samples. This method is subjective and difficult to maintain consistent color judgment.

EP (European Pharmacopoeia) and USP (United States Pharmacopoeia) color standards are commonly used to evaluate liquid pharmaceuticals. Both EP and USP rely on visual assessment. This method has its limitation as it is prone to human error and is subjective. Konica Minolta Spectrophotometer CM-5, equipped with both EP and USP indices, allows users to achieve accurate and repeatable color measurement of pharmaceuticals with ease. It also offers other industrial standard color indices and major colorimetric systems like APHA/Hazen, Gardner, Iodine Color Number, L*a*b*, and and L*C*h.

The new Spectrophotometer CM-M6 is designed to measure the color of complex paints, coatings and plastics. The CM-M6 provides measurement data at six different angles and is ideal for capturing high-end metallic and pearlescent effect paint.

The new Spectrophotometer CM-25cG is designed to measure color and gloss simultaneously. With a forty five zero geometry and a true sixty degree gloss-sensor, this portable spectrophotometer is ideal for measuring automotive interiors.

For liquid chemical products which are yellowish to reddish, color grading scales like the Gardner color scale is commonly used. The earliest form of this scale was made up of 18 standard liquid solutions, and the colored glass scale was introduced afterward to improve stability and accuracy.

Both the liquid and glass scales rely on comparing samples against the standards visually. Both methods are subjective and difficult to maintain consistent color judgment.

Consistency is the key to good quality latex gloves. With growing emphasis on color-coded gloves, color consistency for gloves are getting more stringent. To ensure color consistency, the use of CIE L*a*b* color space, together with a color instrument, express color numerically and allows manufacturers to establish a color control process and meet color quality standards with ease.

Introducing Color Reader CR-20, a portable and simple-to-operate color measurement instrument that is suitable for on-site color evaluation and is commonly deployed in the in-process or outgoing latex glove process as a simple pass/fail gauge.

Konica Minolta color and appearance measurement solutions are widely used within the plastic industry. Portable and benchtop spectrophotometers, appearance meters, and color matching and management software are available to provide accurate results throughout the design and manufacturing process offering users control, traceability, and unmatched accuracy across workstations, sites or within the supply chain for all types of samples including solid, liquid, glossy, transparent, and textured.

Introducing Konica Minolta Color Reader CR-20, a portable and simple-to-operate color measuring instrument that has the necessary color spaces, such as CIE L*a*b* and Yxy, for quick, easy, and objective color evaluation in the in-process or outgoing latex glove manufacturing process.

Introducing the Rhopoint IQ-S 20/60/85 and Rhopoint IQ-S Flex 20. Both the IQ-S 20/60/85 and IQ-S Flex 20 can provide surface appearance parameters like Gloss, Reflectance Haze, Specular Peak Reflection (Rspec), Distinctiveness of Image (DOI) and Reflective Image Quality (RIQ). With comprehensive measurement capabilities, good accuracy, and traceable standards, the IQ-S models are used in the automotive, paint & coating, plastic end products, metal, glass, film, electronics (mobile, display, appliances), and personal care industries and within their supply chain.

An infinite number of colors surround us in our everyday lives.It influence our tastes in food and other purchases, and it can also tell us about that person’s health. Even though colors affect us so much, our knowledge of color and its control is often insufficient, leading to a variety of problems in deciding product color or in business transactions involving color.

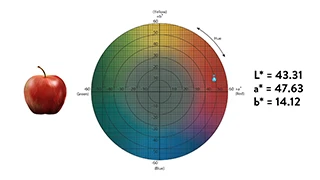

Color perception is subjected to individual interpretation and this makes color communication difficult and vague. To better understand precise color communication, we must first understand the three attributes of color; hue, lightness and saturation. By creating a scales for hue, lightness and saturation, we can then express color numerically.

Metamerism happens when the two objects with the same color appear identical under one light source but different under another light source.This phenomenon is mainly caused by the variations in pigments, dyestuff or materials.

MYIRO is the next level of color management for the printing industry. It features functions to enhance a user’s productivity in a printing process and to get good print quality to increase their profitability.

Products and materials with inconsistent color negatively affect consumer perception and product quality. To meet this challenge, Konica Minolta Sensing, the leading manufacturer of color measurement instruments, offers the new CR-10 Plus Color Reader. This cost-effective technology helps Manufacturers and Quality Assurance professionals worldwide ensure consistent color. With this low-cost instrument, you can measure over-all color difference between targets and samples in an instant.

The CR-A50 and CR-A184 granular material attachments are great tools for providing consistent sample presentation to the CR-400 and CM-700 series instruments. Take a look at our ALL NEW how-to video on sample preparation using the granular attachment accessory. This attachment can be used to measure powders, pastes, grain and other granular substances. The material holder helps eliminate the specimen entering the instrument head and damaging the receptor which results in inaccurate measurements.

The innovative operation of the CM-5 makes color measurement simple for everyone right from the start. The first screen after being switched on lets users select the Operation Wizard, which will guide them through making settings. Automatic calibration can be selected so that calibration is automatically performed immediately after power is switched on each time.

Despite its simple operation, the CM-5 is equipped with a full range of advanced functions for standalone operation and a large color LCD that can show data not just numerically but also on spectral graphs and color plots without the need for a separate computer. Measurements of both reflectance and transmittance are possible, and judgment of PASS/FAIL based on user-set tolerances can be performed.

The CM-600d and CM-700d spectrophotometers are easy-to-use color measurement tools for paint, plastics, and automotive products. In this video, we provide an overview and demonstration on accessory target masks, pivoting bases, and dust covers to maintain your instrument and enhance its performance. These accessories are ideal for wet specimens, powders, or dusty environments. For more information, please visit us online at sensing.konicaminolta.us or shop directly at shopkmsa.com.

At Konica Minolta Sensing we understand the importance of measuring color. Our line of color measurement instruments, software, and accessories are designed to help you communicate, manage, and control the color of your products. Konica Minolta’s CR-400 & CR-410 colorimeters are expertly designed to help improve color consistency and communication.

Norm Demers, Senior Applications Engineer for Konica Minolta Sensing demos the CM-700d spectrophotometer at NPE 2009.

Randy Klimek of Konica Minolta Sensing appears on the Food Detective on Food Network to see if there really are any true blue foods. The CM-700 is used to measure many varies food that are thought to be blue in color.

Norm Demers, Senior Applications Engineer for Konica Minolta Sensing demos the CM-3600 benchtop spectrophotometer at NPE 2009.

The latest Spectroradiometer CS-3000 series from Konica Minolta offers a combination of precision, speed, and innovation. This series comprises three distinct models: the flagship CS-3000HDR, the standard CS-3000, and the cost-effective CS-2000Plus, each designed to address diverse needs and applications.

The Spectroradiometer CS-3000 series delivers unparalleled accuracy and reliability in luminance and chromaticity measurements, proving pivotal for the development and production of various light-emitting devices such as LCDs, OLEDs, Micro LEDs, or Mini LEDs that are found in TV, smartphone displays, and more. These spectroradiometers are indispensable tools for ensuring the highest quality in display technologies, helping manufacturers meet the ever-growing demands for superior visual experiences.

Take your lighting measurements to new heights with the Konica Minolta Chroma Meter CL-200A. This compact and lightweight light meter simplifies the measurement and inspection of various light sources like LED, OLED, and other Organic Electroluminescence (EL). Notably versatile, the CL-200A measures tristimulus values, illuminance, chromaticity, dominant wavelength, excitation purity, correlated color temperature, etc., making it a valuable tool in LED billboard development, interior lighting research, projector light source research, and more. The CL-200A is equipped with a detachable measuring head and offers multi-point measurement options, with the ability to operate up to 30 measurement heads. It also comes bundled with the CL-S10w software, expanding the capabilities with features such as LED ranking, JIS correlated color temperature, user calibration, and more.

In display metrology, CIE 1931 Yxy Chromaticity Diagram and CIE 1976 Yu’v’ Color Space are commonly used to describe colors in numbers. Some of the common display performance parameters includes white balance, color gamut, gamma, contrast ratio, uniformity, and flicker.

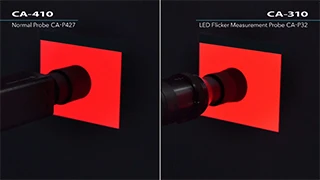

The emergence of High-Dynamic-Range (HDR) display necessitate the need for wider luminance measuring range capable of measuring extremely low to high luminance. With its new sensor circuits, the Color Analyzer CA-410 (successor of CA-310) is capable of providing accurate luminance measurement range from 0.001 to 5,000 cd/m2.

Display gamma influence the overall brightness of an image. Images which are not gamma corrected properly will look either bleached out, or too dark. Konica Minolta Color Analyzer CA-410, with faster range switching and data processing time, can complete a 64 steps RBGW gamma measurement with 30% lesser time (using LTD Auto) as compared to CA-310.

Konica Minolta Sensing Americas introduces a spectacular lineup of measurement instruments used in the automotive industry. The CL-500A Illuminance Spectrophotometer is used for incident lighting and is a spectrally based instrument. The CL-200A Chroma Meter is used for incident light measurements and the CS-200 Chroma Meter is best for point measurements. Experience these instruments for yourself by contacting Konica Minolta Sensing Americas at 888-473-2656 or online at https://sensing.konicaminolta.us

The CL-500A is Konica Minolta’s first compact, lightweight illuminance spectrophotometer that can be used for the spectral evaluation of high class next generation lamps such as LEDs, OLEDs, and EL illumination. It also measures illuminance, chromaticity, color temperature and CRI (Color Rendering Index).

The CL-200A Chroma Meter is the successor to the CL-200. It measures illuminance, color temperature, chromaticity, dominant wavelength, and excitation purity of various light sources, specifically LED, Organic LED (OLED), and other forms of Organic Electroluminescence (EL). It can be used for lighting production and adjustment, evaluating light distribution of LED illumination modules or fixtures, color-viewing cabinet maintenance, LED billboard development, measuring projector light sources and more.

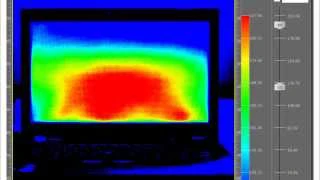

The CA-2500 2D Color Analyzer is an all new display measurement device from Konica Minolta. The CA-2500 is an imaging photometer used by production line manufacturers and research and development teams. High-accuracy measurements of the luminance and color of two dimensional surfaces can be made quickly and easily. Measure luminance and chromaticity of simple displays such as televisions and computer monitors and evaluate the light-emitting areas of automobile instrument panels. The CA-2500 is ideal for the evaluation and inspection of a variety of display technologies such as smartphones and tablet PCs.