Color Formulation and Quality Control of Pellets/Resin

Masterbatch, a concentrated mixture of pigments or additives in a polymer resin, plays a pivotal role in achieving the desired color in plastics manufacturing. Color measurement instruments are integral to masterbatch production, allowing for precise color measurement that helps facilitate accurate color formulation and color quality control of pellets or resin. Konica Minolta offers a comprehensive range of color measurement solutions widely utilized in the plastic industry. Two notable options are the Spectrophotometer CM-5 and Spectrophotometer CM-36dGV, which provide accurate color representation across major colorimetric systems and indices such as CIE L*a*b* and Yellowness index (YI). These versatile instruments are capable of both reflectance and transmittance color measurements, making them ideal for evaluating the color of masterbatches, including resin, pigments, and additives. To ensure consistent and controlled sample preparation, a variety of accessories are available for these instruments, catering to different sample forms ranging from powder and pellet to liquid.

Recommended Products:

Related Links:

Color Quality Control and Verification

Precise color measurement is a fundamental quality control step of molded plastic production. Whether it’s manufacturing preforms or producing plaques and final plastic products, color measurement instruments such as spectrophotometers are utilized to evaluate color accuracy and consistency. Konica Minolta has a range of highly accurate spectrophotometers like the CM-5, CM-36dG, CM-26dG, and CM-700d models. These color measurement instruments enable objective and accurate color measurements of molded plastics, including plastic bottles, sheets, films, and other injection-molded and extrusion-molded parts, ensuring they meet their intended color specifications. With the SCI (specular component included) and SCE (specular component excluded) features, these color measurement instruments can accurately evaluate the color of opaque molded plastics with different levels of gloss and specular reflection. The Spectrophotometer CM-5 and Spectrophotometer CM-36dG also provide transmittance color measurement, enabling accurate and reliable color evaluation of translucent and transparent plastics.

Recommended Products:

Spectrophotometer CM-36dG

Spectrophotometer CM-26dG

Spectrophotometer CM-5

Related Links:

Evaluate Gloss and Surface Finish Quality

Plastics often incorporate various texture effects, such as glossy or matte finishes, which serve both functional and aesthetic purposes. Konica Minolta, partnering with Rhopoint Instruments, has a range of instruments that can evaluate the gloss and other appearance attributes of plastics. One such instrument is the Rhopoint iQ-S, which allows simultaneous gloss measurement at 20°, 60°, and 85° angles, providing a comprehensive evaluation of a wide spectrum of finishes, ranging from matte to high gloss. The Rhopoint IQ Flex 20-S and Novo-Gloss Flex 60, equipped with a remote measuring head, are highly effective options when it comes to precise gloss measurement on small and curved plastic surfaces. Notably, both the Rhopoint iQ-S and Rhopoint IQ Flex 20-S also have the ability to evaluate various appearance attributes, such as reflection haze and DOI (Distinctness of Image).

Recommended Products:

Related Links:

Evaluate Clarity and Visibility

Transmission haze, a phenomenon that can cause a hazy or blurred appearance in transparent plastics, poses a challenge to achieving optimal clarity and visibility. Precise measurement of transmission haze is crucial in ensuring the clarity and visibility of transparent plastics. Konica Minolta, a leading provider of color measurement instruments, offers a range of spectrophotometers that can quantify transmission haze in transparent plastics. The lineup includes the Spectrophotometer CM-5, Spectrophotometer CM-36dG, and Spectrophotometer CM-3700A, known for their exceptional precision and reliability. By leveraging these instruments with QC analysis software like SpectraMagic NX Pro Software, they can provide fast and easy correlated haze measurement, enabling plastic manufacturers to achieve exceptional quality control in their transparent plastics.

Recommended Products:

Spectrophotometer CM-36dG

Spectrophotometer CM-5

Spectrophotometer CM-3700A

Related Links:

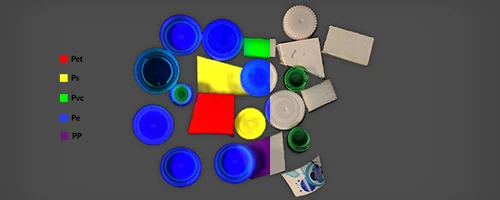

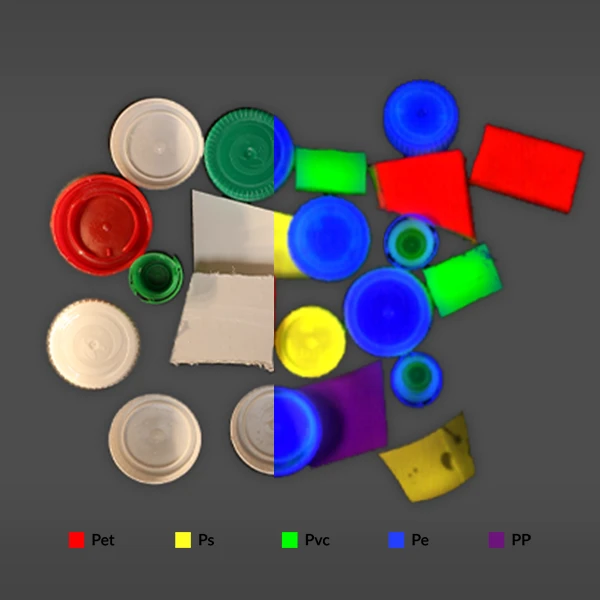

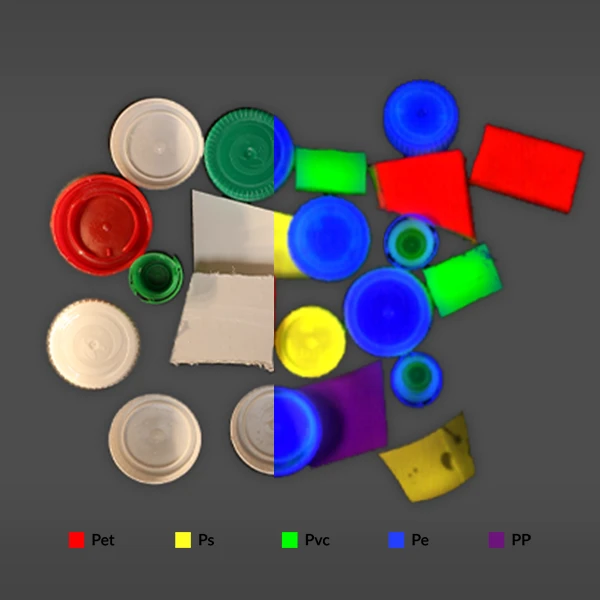

Plastics Classification with Hyperspectral Imaging

Hyperspectral imaging is a transformative technology that greatly improves the accuracy, efficiency, and effectiveness of plastic sorting and recycling processes. It has the ability to identify and classify objects that may have similar appearances but different compositions, surpassing the limitations of conventional imaging methods such as RGB and human visual inspection. Konica Minolta and group company Specim offer a range of fast and powerful hyperspectral imaging systems for various industrial inspection applications. Particularly, the Specim FX Series hyperspectral cameras, with their exceptional spectral resolution and frame rate, enable accurate and rapid identification and classification of different plastic types, including PET, HDPE, PVC, PP, PS, PE, ABS, etc., on high-speed sorting lines.

Recommended Products:

Related Links:

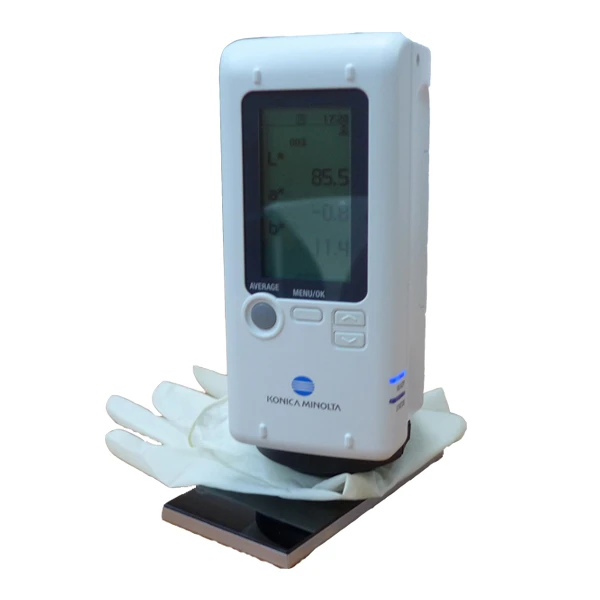

Color Quality Control and Verification

Color is an important element of latex, nitrile, and other rubber gloves, serving practical, safety, and regulatory purposes. Precise color measurement solutions are essential for ensuring accurate color coding and consistency in glove manufacturing. Konica Minolta offers a range of highly reliable spectrophotometers and colorimeters that can be utilized at various stages of glove production, from compounding to quality assurance (QA) and quality control (QC). One of these remarkable instruments is the Spectrophotometer CM-5, capable of accurately measuring the color of various samples, whether powder, granular, paste, or liquid form. Its precise and versatile color measurement capabilities enable it to evaluate the color of gloves and their compounding ingredients like latex concentrate, pigments, and fillers. The tinting strength of pigments can also be calculated when leveraging the versatile Spectrophotometer CM-5 with the SpectraMagic NX Pro Software. For quick quality inspection checks on the color and opacity of latex, nitrile, and other rubber gloves, the Color Reader CR-20 is an excellent option.

Recommended Products:

Related Links:

Plastic Industry Color and Appearance Measurement Solutions

Konica Minolta offers a comprehensive range of color and appearance measurement solutions that are widely utilized in the plastic industry, from portable and benchtop spectrophotometers to appearance meters and color matching and management software that provide accurate results throughout the design and manufacturing process, offering users control, traceability, and unmatched accuracy across workstations, sites, or within the supply chain for all types of samples including solid, liquid, glossy, transparent, and textured. Watch this video to explore our range of measurement solutions for the plastic industry now.