Color Specification, Control, and Verification

Precise color measurement solutions play a pivotal role across various stages of decorative paints and coatings manufacturing. These solutions facilitate precise color formulation, quality control, and color matching and also contribute to new decorative paints and coating color and shade development. Konica Minolta has a wide selection of color measurement instruments that can help ensure accurate color formulation, quality control, and color consistency of decorative paints and coating. Among these, the Spectrophotometer CM-36dG and Spectrophotometer CM-26dG provide excellent inter-instrument agreement, ensuring consistent and accurate digital color management and communication throughout the supply chain.

Recommended Products:

Related Links:

Measure Color of Painted Objects

While industrial paints and coatings are primarily chosen for their functional benefits, their visual appearance, including color consistency and accuracy, still holds considerable importance for safety, quality perception, or even the overall performance in industrial applications. Konica Minolta has several reliable spectrophotometers, including the CM-700d, CM-26dG, and CM-36dG, which provide objective and accurate color measurements for various industrial paint and coating applications. These spectrophotometers enable precise color specification, effective color communication, and data-driven process control and quality control. Notably, the Spectrophotometer CM-700d and Spectrophotometer CM-26dG have small measuring apertures, facilitating easy color measurement of small painted parts.

Recommended Products:

Spectrophotometer CM-700d

Spectrophotometer CM-26dG

Spectrophotometer CM-36dG

Related Links:

Characterizing Metallic and Special Effect Colors

Measuring the color of metallic, pearlescent, and other special effect paints can be challenging due to their tendency to exhibit color shifts under different illumination and viewing conditions. Overcoming these challenges requires the use of specialized instruments like the Konica Minolta Multi-Angle Spectrophotometer CM-M6. It can measure the color and appearance of these paints from various viewing angles, ranging from -15° to 110°, making it a valuable tool for characterizing complex and angle-dependent color shifts. The Multi-Angle Spectrophotometer CM-M6 has a small measuring area of 6 mm, enabling color measurement of small parts or surfaces.

Recommended Products:

Related Links:

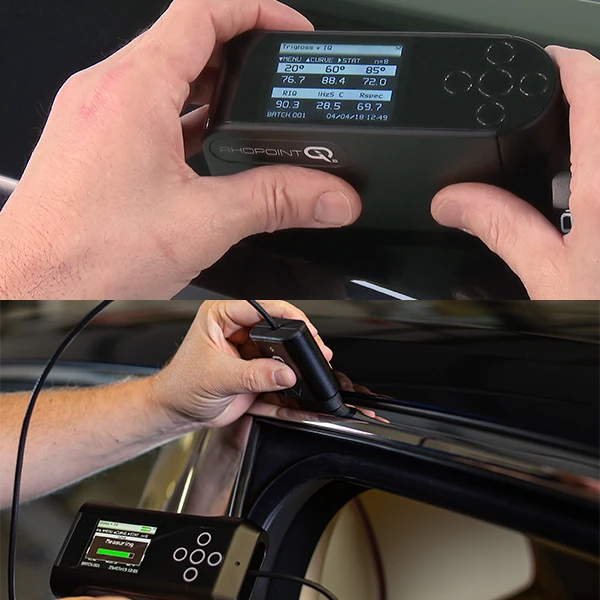

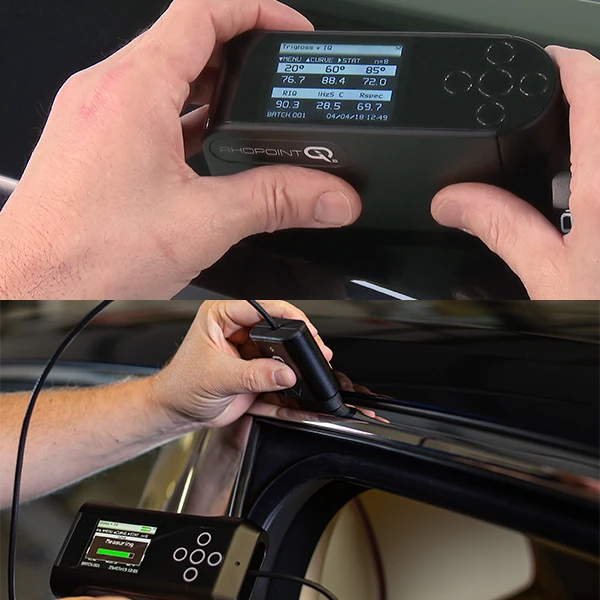

Gloss, Reflection Haze, and Orange Peel (DOI) Measurement

Gloss meters are valuable tools for evaluating the glossiness of painted or coated surfaces. However, they have limitations when it comes to detecting and quantifying defects like reflection haze and orange peel. Comprehensive quality control of painted and coated surfaces often involves the use of multiple measurement tools like gloss meters, haze meters, and DOI (Distinctness of Image) meters. The Rhopoint iQ-S and the Rhopoint IQ Flex-20-S are versatile instruments that combine various critical parameters, like gloss, reflection haze, DOI, and RIQ (Reflected Image Quality), into a single device, allowing for efficient and accurate assessment of the finishing quality of painted and coated surface. The Rhopoint TAMS™ is another advanced instrument used for evaluating finishing quality, particularly for assessing complex textures and finishes. It offers new parameters like contrast, sharpness, waviness, dimension, etc., enabling the evaluation of orange peel and surface roughness that better correlate with human perception of surface appearance quality.

Recommended Products:

Related Links:

Color Specification, Control, and Verification

Pigments are the primary components responsible for imparting color to paints and coatings. Color measurement instruments like spectrophotometers are commonly used to ensure the accuracy and consistency of pigment colors. Konica Minolta, a leading provider of color measurement solutions, offers a range of highly accurate spectrophotometers with traceability, like the CM-5 and CM-36dG models. These instruments enable precise color specification, effective communication, and consistent color quality control of pigments used in paints and coatings. With various color measurement modes, including reflectance and transmittance, and a wide selection of accessories, both the Spectrophotometer CM-5 and Spectrophotometer CM-36dG can handle samples in different forms, such as solid, powder, paste, and liquid. This versatility allows for the color measurement of other raw materials like binders, additives, solvents, and more.

Recommended Products:

Related Links: