Improving Plastics Manufacturing with Digital Color Standards

Plastic manufacturing is a complex and rapidly changing industry, and the need for accurate color standards is imperative. Using digital color standards can make this process easier, faster, and more accurate. It offers a more objective metric for communicating the desired colors of the plastics, like thermosetting plastics or thermoplastics, before it is created. This helps to minimize miscommunication between different parties (e.g., raw materials suppliers, masterbatchers, molders, etc.) and ensures that all involved understand the exact final appearance and color of the plastics. Furthermore, it provides a way to create and control color without relying on physical color standards (e.g., swatches or chips), which can be costly and time-consuming to produce. This can help plastic manufacturers minimize bottlenecks occurring due to manual matching processes and delays associated with physical color standards, offering a faster time-to-market and a more efficient plastics manufacturing process.

Spectrophotometer to Create Digital Color Standard

Creating and using digital color standards would require an accurate and repeatable spectrophotometer. Below are some key points to keep in mind when selecting a spectrophotometer.

- Use spectrophotometers with good Inter instrument agreement (IIA) for more consistent and reliable measurement results across different locations. IIA defines how close two or more spectrophotometers of the same model measure the same color, and the smaller the IIA value, the closer the color measurement results will be. This is essential for ensuring the color consistency of the plastics, especially for plastic manufacturers with multiple facilities and supply chains on a global scale

- Different types of plastics (e.g., opaque, translucent, transparent, etc.) require different measurement modes to achieve reliable color measurement data. Reflectance measurement mode is recommended for solid or opaque plastics that don’t allow light to pass through. Transmittance measurement mode is best suited for translucent or transparent plastics that allow light to penetrate through them.

- Glossy plastic will typically appear darker than matte plastic of the same color. For color measurement that correlates with visual perception, it is recommended to use either a spectrophotometer with 45°/0° geometry or a spectrophotometer with d/8° sphere geometry in specular component excluded (SCE) But to measure the “true color” of the plastics, excluding their surface finish, a spectrophotometer with d/8° sphere geometry in specular component included (SCI) mode is required.

Standardizing the Color Measurement Process

A detailed methodology should be included alongside the digital color standard and shared with all parties involved in the plastics production to ensure color consistency. An example of a well-defined methodology includes:

- The configuration used to measure the colors of the plastic. For example, the spectrophotometer’s model and geometry, standard observer and illuminant set on the spectrophotometer, measurement mode (e.g., reflectance or transmittance), color space, and color tolerance used, etc.

- The basic setup on how the plastics are being prepared and presented for measurement for consistency. It is helpful to document the accessories used, the measurement points, instrument orientation, the number of measurements taken, etc.

Konica Minolta Spectrophotometers for Digital Color Measurement

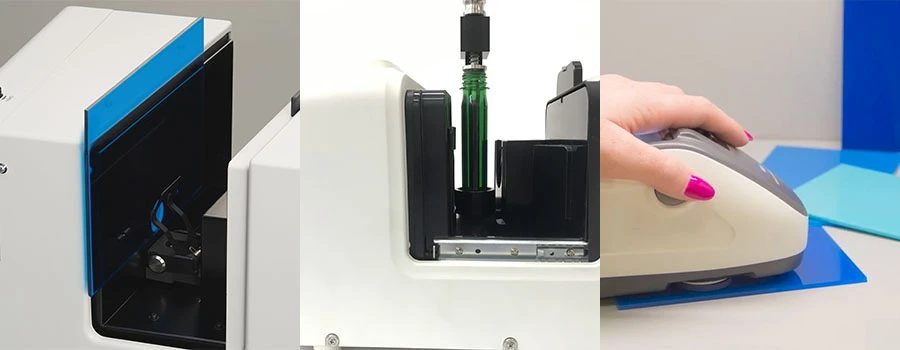

Konica Minolta offers a wide selection of close tolerance grade spectrophotometers that can support the implementation of digital color standards and digital color management workflow in plastics manufacturing. These color measurement instruments include Spectrophotometer CM-3700A, Spectrophotometer CM-36dG, and Spectrophotometer CM-26dG with d/8° sphere geometry, as well as Spectrophotometer CM-25cG with 45°/0° geometry. In addition to color measurement, the CM-36dG, CM-26dG, and CM-25cG also come with an integrated gloss sensor, enabling simultaneous measurement of color and gloss. Watch the CM-36dG, CM-26dG, and CM-25cG videos to learn more about their capabilities in detail.

Plastics color measurement with Spectrophotometer CM-3700A (left), Spectrophotometer CM-36dG (center), and Spectrophotometer CM-26dG (right)

Need help creating digital color standards or digital color management workflow for your plastics production? Or perhaps require assistance to find the right color measurement instruments or solutions? Contact our color specialists for a free consultation now.