Understanding the Effects of Gloss in Color Measurement

Design knows no limit. Many manufacturers are incorporating texture effects like high gloss or matt finishes to enhance their product appearance. This combination can pose new challenges to manufacturers when color management is concerned.

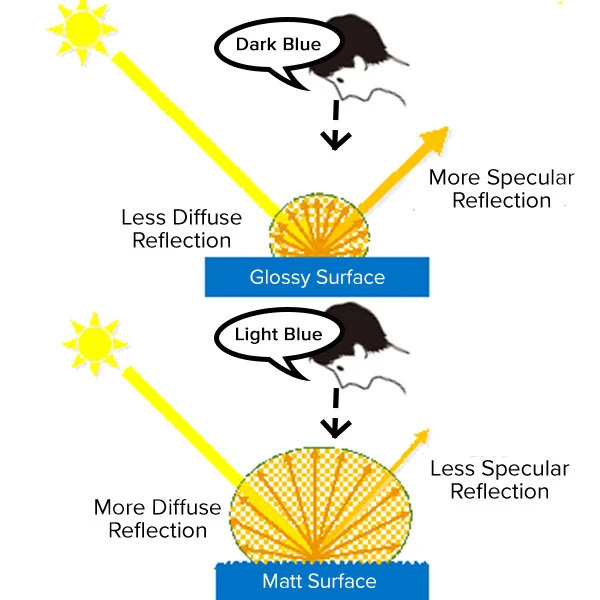

Two objects with similar L*a*b* values but differing gloss values can exhibit difference between their appearance. An object’s surface condition influences how light is reflected, and this reflected light creates what we perceive as color. If an object has a glossy surface, most of the light will be reflected off the surface like a mirror (specular reflection). When evaluating the lightness of glossy objects, we tend to ignore the specular reflection therefore glossy objects appear darker in shade. Conversely, object with matt surface reflects light in many directions (diffuse reflection) which make the object appear lighter in shade. For manufacturers, it is important to evaluate both color and gloss to determine whether the visible difference is due to color or gloss as corrective action for color is different from gloss.

When attempting to evaluate color and gloss in today’s globalized supply chain network, the use of Spectrophotometer CM-26dG would be helpful. With d:8 geometry and integrated 60° gloss sensor that is capable of both Specular Component Included (SCI) and Specular Component Excluded (SCE) measurement mode, the CM-26dG can measure color and gloss simultaneously without the need to switch and reposition additional gloss meter.

With tight Inter-Instrument Agreement (IIA) of ∆E*ab< 0.12 (average of BCRA 12 Tiles) and ±0.2 GU (0 – 10 GU), manufacturers can be confident that the intended color and gloss can be communicated, coordinated and managed seamlessly throughout the supply chain. Check out this video to learn more about CM-26dG.

Interested to find out more about color and gloss measurement? Get in touch with us for a free consultation on how you can account for gloss when measuring color.