Hyperspectral Imaging for Plastic Classification

Plastics are widely used materials in our daily lives, ranging from packaging to electronics. However, with increasing production and usage of plastics, waste management has become a major concern globally. The improper disposal of plastic waste causes serious environmental issues, such as pollution of land and water bodies. It is, therefore, imperative to develop efficient methods for managing and recycling plastic waste to address these issues effectively.

Conventional approaches to sorting and classifying plastic waste primarily rely on visual inspection, a process that is both time-consuming and vulnerable to errors. However, with the advancements in technology, hyperspectral imaging has emerged as a promising solution for precise and efficient plastic classification.

What is Hyperspectral Imaging?

Hyperspectral imaging is an advanced technology that goes beyond the capabilities of traditional imaging methods. Unlike standard imaging methods that capture images in three bands (red, green, and blue), hyperspectral imaging combines the power of spectroscopy and digital imaging, capturing information across hundreds or even thousands of narrow, contiguous bands throughout the electromagnetic spectrum. This advanced imaging technique allows for the acquisition of highly detailed spectral data for each pixel in an image. By analyzing the unique spectral signatures of different materials, hyperspectral imaging provides a wealth of information that is invaluable for a wide range of applications.

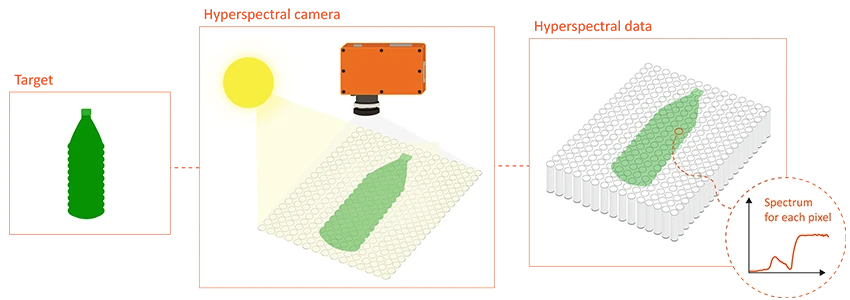

Illustrative example of hyperspectral imaging

Hyperspectral imaging’s key advantage resides in its ability to identify and differentiate between different types of materials, even those that may appear visually indistinguishable. This is especially useful in industries such as plastic recycling, where accurate identification and sorting of plastics is crucial for efficient processing.

How Does Hyperspectral Imaging Work for Plastic Classification?

A typical hyperspectral imaging system comprises a hyperspectral camera and an illumination source. The process of hyperspectral imaging begins by illuminating an object with a broad range of light wavelengths. The hyperspectral camera then captures the reflected or absorbed light at various wavelengths. Advanced algorithms are utilized to process the captured images, generating a distinct spectral signature for each material present in the image, enabling precise identification and analysis of different materials within the image.

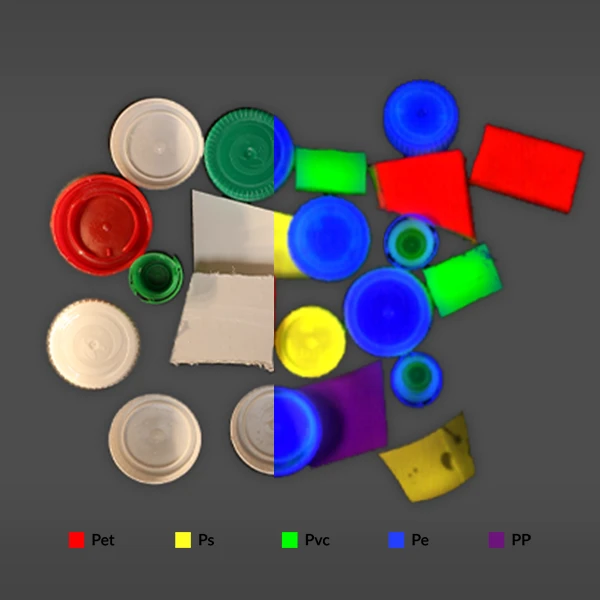

Plastics possess distinct spectral signatures that can be differentiated based on their chemical composition, additives, surface properties, etc. Through the utilization of hyperspectral imaging, the spectral signature of a plastic sample can be compared to a database of known signatures, enabling accurate identification and classification of various plastic types within a mixture. In addition, hyperspectral imaging can also detect and classify contaminants in plastics, such as paper labels or different types of materials mixed with the plastics.

Specim Hyperspectral Imaging Cameras for Plastic Classification

Specim, a member of the Konica Minolta Group, is a leading provider of hyperspectral imaging solutions. The company offers a diverse range of push-broom (line scan) hyperspectral cameras that have gained widespread use in diverse fields, including agriculture, food, pharmaceuticals, medical science, and art conservation. One of the most versatile hyperspectral cameras from Specim is the FX series, which has found extensive applications in industrial quality control and inspection. Notably, the Specim FX series has been successfully utilized in plastic classification applications, with companies like Picvisa and Prodecologia developing plastic sorting machines using the Specim FX series hyperspectral camera. Picvisa, a company experienced in machine vision solutions for recycling and industrial processes, has integrated the Specim FX series into its plastic sorter system. The polymer sorting machine developed by Prodecologia also employs the Specim FX series hyperspectral camera.

The Specim FX series hyperspectral camera offers a remarkable advantage with its high resolution and high frame-rate capabilities. It enables reliable and rapid identification and classification of different plastic types, such as PET, HDPE, PVC, ABS, PE, PS, and more, even on high-speed sorting lines.

Classifying different plastics with Specim FX17 hyperspectral camera

In addition to its exceptional functionality, the Specim FX series hyperspectral camera is designed to facilitate flexible and effortless installation, whether on new or existing sorting lines. Watch this video to learn more about the hyperspectral camera Specim FX series.

Are you interested in implementing hyperspectral imaging into your applications? If so, get in touch with us for a free consultation, and let us assist you in finding the right hyperspectral cameras and solutions tailored to your needs.