Ensuring Food Safety with Hyperspectral Imaging

Every year, millions of people worldwide are impacted by food safety issues. One critical aspect of preventing these issues is food inspection, which involves identifying harmful contaminants or defects in food products. The traditional approach to food safety inspection relies on human inspectors to detect defects with their senses – visual, smell, or texture. But this method is highly subjective and prone to human error. Another common food safety inspection method involves extracting samples from food and analyzed in a laboratory. The analysis includes a wide range of tests, including microbiological and chemical. While this method is more scientific, it often involves the destruction of a portion of the sample in order to extract and analyze the relevant components. Furthermore, the results may also not be immediately available. In recent years, hyperspectral imaging has emerged as one of the promising tools for food safety inspection.

What is hyperspectral imaging?

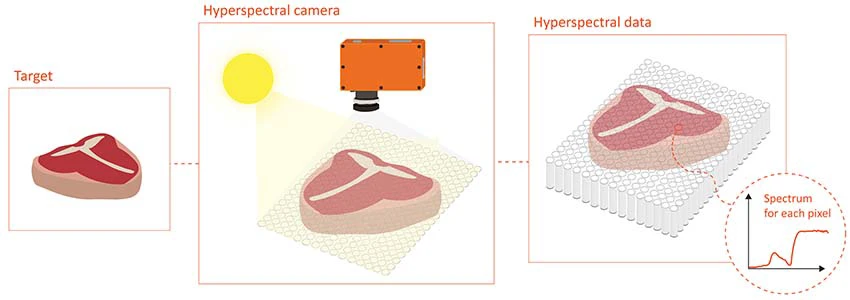

Hyperspectral imaging is a non-destructive technique that uses a combination of spectroscopy and imaging to analyze the properties of materials. It involves capturing and processing images of a scene in many narrow, contiguous spectral bands, typically covering the visible and near-infrared portions of the electromagnetic spectrum. Each pixel in the hyperspectral image contains a full spectrum of information, rather than just the red, green, and blue color channels captured in a regular imaging camera. By analyzing the spectral content of each pixel in a hyperspectral image, it is possible to obtain detailed information on the chemical composition of the object.

Illustrative example of hyperspectral imaging.

Hyperspectral imaging is a versatile technology used in various fields like agriculture, waste sorting, healthcare, and art conservation. In the context of food safety, hyperspectral imaging helps in identifying the presence of contaminants, pathogens, and spoilage, including assessing the quality of food products.

How does hyperspectral imaging improve food safety inspection?

Compared to traditional food safety inspection methods, hyperspectral imaging offers multiple benefits. One significant advantage is its non-invasive nature, which allows food products like fruits, vegetables, or meats to be examined without damaging them. Hyperspectral imaging can detect contaminants or defects that may not be visible to our eyes. For example, it can detect discoloration or mold in nuts, including foreign objects like shells or insects, which may be difficult to spot through visual inspection. Hyperspectral imaging can also provide objective and quantitative measurements of food quality. It can determine factors such as ripeness, moisture content, and texture, which are important for maintaining quality standards and ensuring that food is safe for consumption.

Numerous studies have demonstrated the potential of hyperspectral imaging in various food safety applications. For example, Siripatrawan et al. (2011) used hyperspectral imaging to detect E. coli contamination in spinach. Zhang et al. (2007) utilize hyperspectral imaging to develop a classification algorithm for differentiating wheat kernels infected by different fungal species (Aspergillus niger, Aspergillus glaucus, and Penicillium spp.). Peng et al. (2011) used hyperspectral imaging to predict the presence of total viable microorganisms in beef. Typically utilized wavelength ranges for food applications are the visible-near infrared (VNIR), near infrared (NIR), and shortwave infrared (SWIR).

Specim Hyperspectral Imaging Camera For Food Safety Inspection

Specim, part of Konica Minolta Group, is a trusted provider of hyperspectral solutions in the food industry. Specim offers an extensive range of pushbroom (line scan) hyperspectral cameras and solutions that are widely used in various food quality and safety applications. Whether you are in the lab or on the production floor, Specim has you covered, from portable hyperspectral camera Specim IQ suitable for laboratories or on-site operations usage to the industrial-grade hyperspectral camera Specim FX series that can seamlessly integrate with your existing machine vision system.

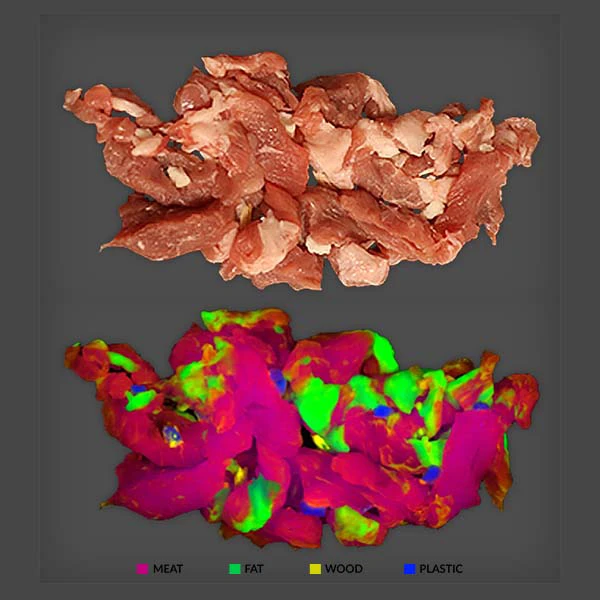

Hyperspectral images of meat taken with hyperspectral camera Specim IQ (left) and hyperspectral camera Specim FX17 (right).

Image courtesy of SPECIM, SPECTRAL IMAGING LTD.

The Specim IQ and FX Series hyperspectral cameras are the perfect tools for any application requiring precise imaging capabilities. Check out the Specim IQ and Specim FX Series videos to explore their features, benefits, and performance.

Need help finding the right hyperspectral cameras or solutions for your specific food application? Get in touch with our team of experts for a free consultation to discuss your needs and challenges.