Bruise Detection of Fruits Using Hyperspectral Imaging

Fruits that are bruised can have a significant impact on their overall quality and shelf life. Bruising causes the fruit to soften, which makes it more vulnerable to decay and other spoilage issues. Bruised fruits also tend to lose flavor, texture, and nutritional value over time. Additionally, bruising can make fruits susceptible to attack by pests or pathogens, leading to further spoilage. As such, bruise detection is an important quality control measure in the fruit industry. However, conventional methods of detecting bruises rely on manual inspection, which is subjective. Furthermore, the efficiency and accuracy tend to drop after a few hours of continuous inspection. In an attempt to minimize inspection errors and improve efficiency, many turn to automated inspection technology such as machine vision systems. Conventional machine vision systems are based on RGB (red, green, and blue) cameras or sensors. They are capable of detecting fruits with obvious defects through changes in color. However, they are unreliable when it comes to identifying latent bruise damage that is subtle and has inconsistent color variance between the bruised and the normal tissues.

Hyperspectral Imaging

A better approach to rapid and accurate bruise detection of fruits is through hyperspectral imaging (HSI). A combination of optical imaging and spectroscopy, HSI is already widely used in many inspection applications within the food industry, like meat, nuts, etc. HSI’s capability to detect bruises on fruits is also well-documented in various research. For instance, Lu (2003) is able to detect bruises on apples effectively using NIR (Near-Infrared) HSI. VNIR (Visible and Near-Infrared) HSI showed good potential in detecting bruises on pears and kiwifruits, as demonstrated by Wang et al. (2022) and Lu et al. (2011), respectively.

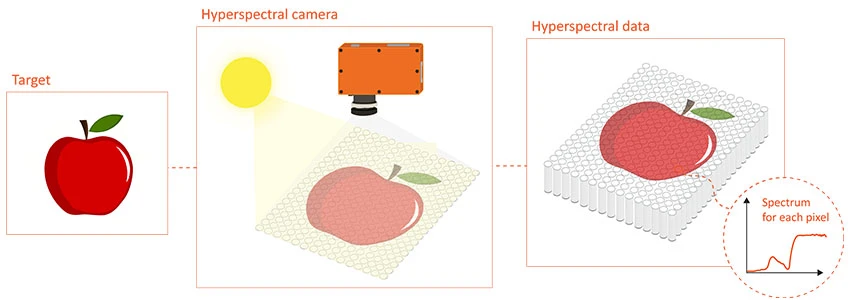

Illustrative example of hyperspectral imaging

HSI works by acquiring images of fruits over a contiguous range of spectral bands, providing higher levels of detail and accuracy for analyzing features related to bruising. Using HSI-derived data, it can distinguish between bruised and unbruised fruit with high accuracy, even for fruits with latent bruise damage. For example, HSI can measure changes in reflectance that are associated with bruising. This data can then be used to train a machine-learning model to detect bruises in fruits with even greater accuracy.

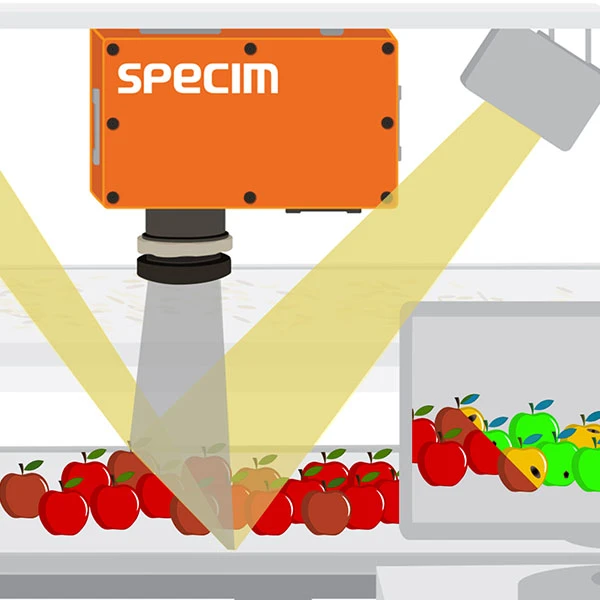

Specim Hyperspectral Imaging Camera for Detecting Bruises on Fruits

Specim Hyperspectral Imaging Camera for Detecting Bruises on Fruits

Specim, a leading provider of hyperspectral imaging solutions, offers several line scan (pushbroom) hyperspectral cameras, from portable models to advanced industrial models, which are used extensively across multiple food science food science and inspection applications. The Specim FX series, particularly the VNIR hyperspectral camera FX10 and the NIR hyperspectral camera FX17, are excellent choices when it comes to detecting bruises on fruits, even in the early stages, before they are visible to the naked eye. Designed for easy integration, even with an existing machine vision system or optical sorting system, both the FX10 hyperspectral camera and the FX17 hyperspectral camera offer a high frame rate capable of meeting production or sorting high-speed demands. Check out the Specim FX10 and FX17 videos to learn more about their capabilities.

Do you want to learn more about HSI and find the right hyperspectral cameras and solutions for your applications or project? Our specialists are here to provide a free consultation. Connect with us now.