Food Quality and Safety Inspection With Hyperspectral Imaging

The quality and safety of foods have always been of great importance for consumers and regulatory authorities. Inspecting the external appearance and composition of foods can help meet the quality and safety standards and also the expectation of the consumers. There are several methods available to inspect the sensory attributes and composition of food. Unfortunately, some of the current prevalent methods require laboratory analysis that is labor-intensive, time-consuming, and often involves the destruction of samples.

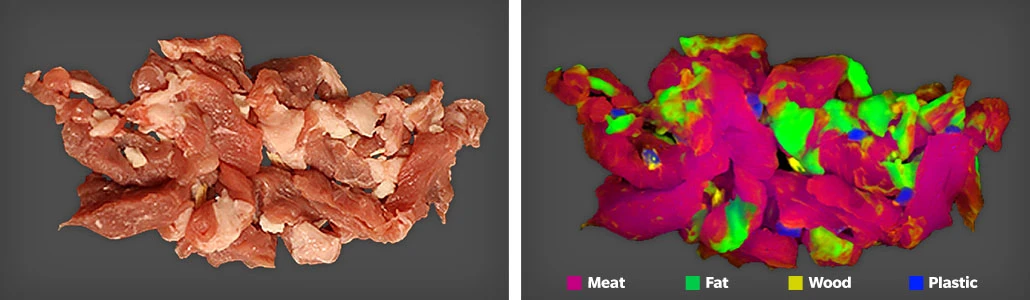

In recent years, hyperspectral imaging (HSI) is a non-invasive technique rapidly growing within the agriculture and food industry. It measures the interaction between the light (reflection, transmission, etc.) and material through a hyperspectral camera to obtain spectral signatures or spectral fingerprints of the material. Every material has its unique spectral signatures, and these spectral signatures contain quantifiable information that can further be used to characterize, identify, and discriminate materials. As shown in figure 1, HSI can simultaneously and quickly characterize the fat content in the meat and detect undesired objects like wood and plastic from the meat.

Figure 1 – HSI detecting foreign material and characterizing fat content in meat. Image courtesy of SPECIM, SPECTRAL IMAGING LTD.

The full-spectral imaging and the detection capability of HSI make it ideal for various applications within the food industry. Below are some of the well-tested applications of HSI.

• Detecting blemishes, bruising, and chilling injury.

• Measuring ripeness and chemical quality like sugar content, anthocyanins content, moisture contents.

• Detection of contamination and undesired objects such as wood, paper, insects.

• Measuring meat tenderness and compositions such as fat, protein, water content, etc.

• Detection of contamination and undesired objects like bone fragments, plastics, wood, etc.

While HSI has become a viable solution for the food industry, the measurement and processing of hyperspectral data can be challenging for people without knowledge or prior experience in HSI.

HSI is made simple with the Specim IQ. A mobile and stand-alone hyperspectral camera based on the pushbroom principle, the Specim IQ offers simple operation with minimal user input, similar to a digital camera. Complicating data processing are behind an easy-to-use graphic interface , allowing anyone from beginners to experts in HSI to get instant measurement results and insights with ease. Users can also develop and upload their applications and data processing algorithms into the Specim IQ through the Specim IQ Studio software.

HSI is made simple with the Specim IQ. A mobile and stand-alone hyperspectral camera based on the pushbroom principle, the Specim IQ offers simple operation with minimal user input, similar to a digital camera. Complicating data processing are behind an easy-to-use graphic interface , allowing anyone from beginners to experts in HSI to get instant measurement results and insights with ease. Users can also develop and upload their applications and data processing algorithms into the Specim IQ through the Specim IQ Studio software.

The Specim IQ combine simplicity, high performance, and versatility. Watch this video to find out more.

Interested to understand more about HSI or need assistance setting up an HSI system for your application? Get in touch with HSI experts for a free consultation now.