What Is Calibration and When Is It Needed?

Calibration is a process of checking and adjusting the accuracy of measuring instruments by comparing against a reference standard. The reason for calibration is to ensure measurements are accurate and readings taken from one instrument or factory to another is consistent with each other. Inconsistent measurement values or instruments failures translate directly into inconsistent products and can be disastrous in term of rectification cost and market appeal.

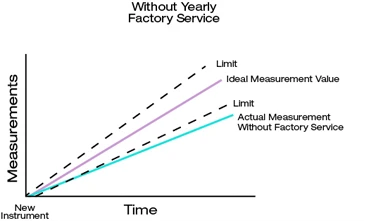

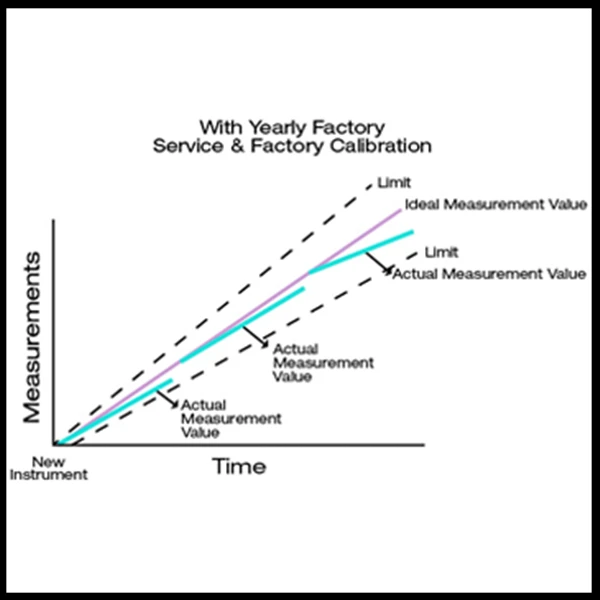

Even the most expensive and precise color measuring instruments can be damaged during handling or degrades over time. It is imperative that all color measuring instruments such as the spectrophotometers and chroma meters are calibrated and monitored on a regular basis, conforming to well-established quality management systems or standards like the six sigma or ISO requirement of inspecting and recalibrating instruments at regular intervals.

Calibration can be differentiated into daily or annual calibration. Daily calibration is a simple and straightforward procedure where customers can perform themselves while an annual calibration requires customers to send their instruments over to Konica Minolta’s authorized service facility where certified technicians would be available to perform the calibration.

At Konica Minolta Sensing, customers are always guaranteed the same high level of service and care that was put into manufacturing the instruments. And with a wide service network, customers can easily access to Konica Minolta’s authorized service facility locally.

To understand more about the calibration process, click here. Alternatively, you may call us at 6563 5533 to learn more about our calibration services.