Rhopoint TAMS™

In the automotive industry, color is not the only important parameter to describe a high-quality paint finish. Brilliance (gloss) and smoothness, often referred to as DOI (Distinctness of Image), are equally important. To achieve maximum visual impact, overall surface finish must display both high quality and harmony.

In the automotive industry, color is not the only important parameter to describe a high-quality paint finish. Brilliance (gloss) and smoothness, often referred to as DOI (Distinctness of Image), are equally important. To achieve maximum visual impact, overall surface finish must display both high quality and harmony.

Rhopoint TAMS™, inspired by a four-year collaboration between Rhopoint, Volkswagen AG and AUDI AG, is a new way of quantifying appearance quality. Equipped with new parameters, this innovative new technology mimic human perception of surface appearance quality, providing easy and fast communication of visual appearance information.

Rhopoint TAMS™ has the ability to capture surface data ranging from mid gloss to high gloss, offering the possibility of quantifying all surfaces such as E-Coat, filler, base coat and top coat aluminum and steel, throughout the automotive manufacturing process.

Raw Material Measurement

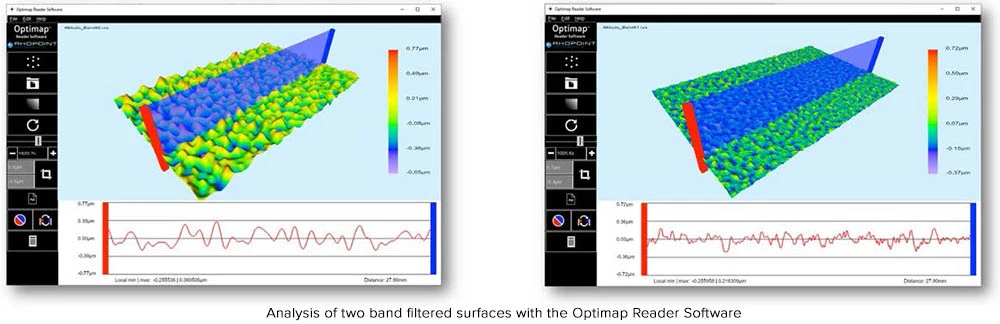

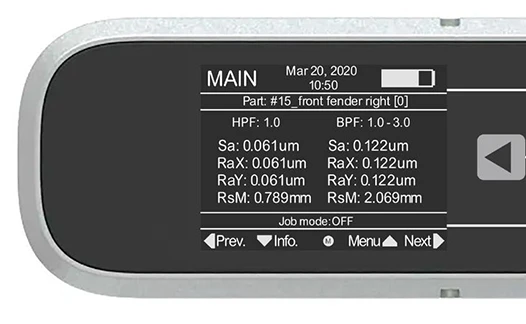

Data like 3D topographical maps helps better understand how each painting process fills, smooths, and masks the roughness from the base material like aluminum and steel. Laboratory devices which produce 3D topographical maps are often costly and complex to use. Rhopoint TAMS™, with its free Optimap Reader image analysis software and Phase Measurement Deflectometry (PMD) measurement technologies, provides fast and high-resolution 3D altitude maps of raw materials and surfaces in the painting process that comply with ISO 16610. The measurements like areal topographic information (Sa) and optical Ra are also taken as per DIN EN ISO 25178 and DIN EN ISO 4287.

E-Coat Measurement

E-Coat Measurement

E-coating, also called Electrophoretic Painting, Electrocoating, Electropainting, has a huge impact on the final quality. Rhopoint TAMS™ and its advanced quality parameters like topographic roughness indices (Sa) provide a complete overview of the painting process, offering easy documentation, reporting, and better control of E-coat. Besides analyzing the topographic indices, this innovative appearance measurement instrument also comes with advanced quality indices to help judge the E-coat overall quality.

E-coating, also called Electrophoretic Painting, Electrocoating, Electropainting, has a huge impact on the final quality. Rhopoint TAMS™ and its advanced quality parameters like topographic roughness indices (Sa) provide a complete overview of the painting process, offering easy documentation, reporting, and better control of E-coat. Besides analyzing the topographic indices, this innovative appearance measurement instrument also comes with advanced quality indices to help judge the E-coat overall quality.

C-Coat Measurement

Contrast

Related to the color of the surface where white and metallic surfaces exhibit low contrast while black surface has high contrast. This parameter quantifies the visual impact of both haze effects and orange peel which are visible on high contrast colors.

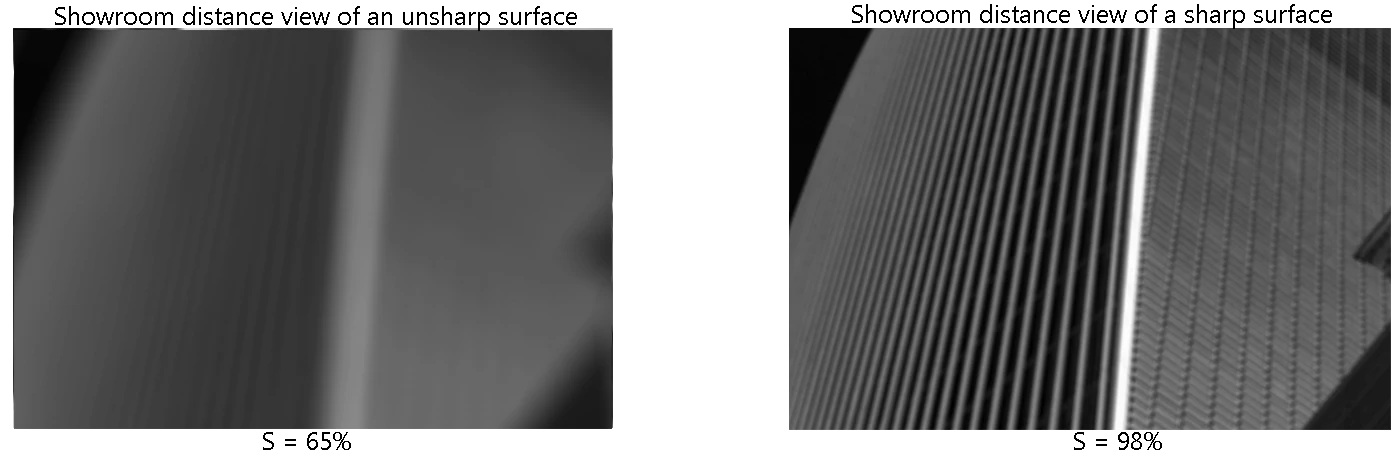

Sharpness

Sharpness measures the accuracy of the reflected images. Sharpness defines how well a surface reflects fine details at close distances (<0.5m). At showroom viewing distance (1.5m), it quantifies clarity and haze.

Waviness

Waviness of a surface is vital in establishing appearance quality as it measures the visible impact of surfaces waves to observer at showroom distance (1.5m).

Dimension

Dimension indicates the dominant structure size, an important parameter in determining the harmony between adjacent parts and panels, viewed at showroom distance (1.5m). Values are usually between 1–6mm.

Quality

Calculated using Sharpness and Waviness parameters, the Quality index rates the total appearance quality of a surface. Smooth finish with perfect image forming characteristics is indicated by 100%

Harmony

Calculated using Waviness and Dimension parameters, the Harmony index determines the acceptability of adjacent car parts. A >1.0 value would indicate that parts are dissimilar when viewed together and will reduce the overall visual quality.