How To Measure Reflection Haze?

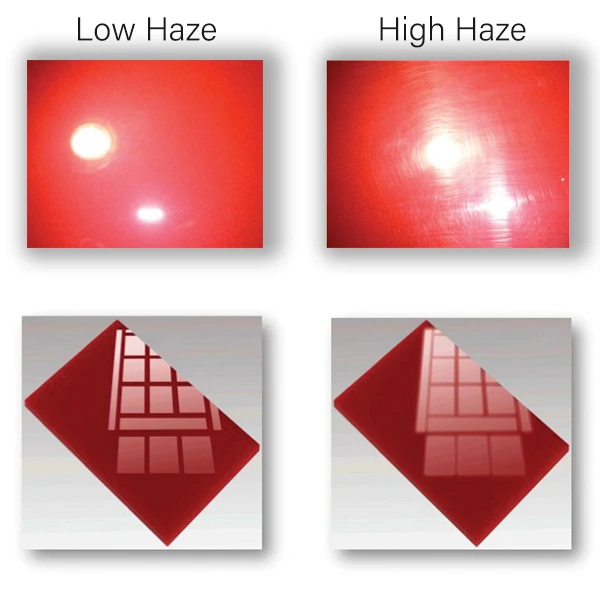

A crucial factor in assessing the appearance of any manufactured product is its highly reflective and smooth finishes and one barrier to achieving such finish is reflection haze.

Reflection haze, caused by micro textures on a coated surface, can result in poor reflective image contrast on surface with halos around it. It is a common problem in coating applications like automotive, powder coatings and high gloss coatings. Refection haze is caused by poor dispersion, raw material incompatibility, polishing marks, stoving, drying or curing conditions.

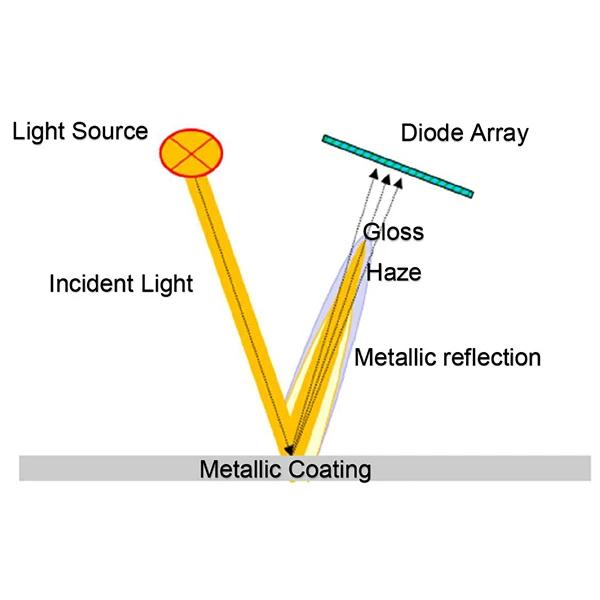

Traditionally, gloss-haze meters are used to measure the reflection haze parameter. However, it has fixed optics which make haze measurements on a curved surface unreliable. This is because the surface will reflect light away from the centre of the sensor. For high reflective and metallic coating, a certain amount of diffuse light, due to the metallic flake, can cause inaccurate and higher than expected haze reading.

Appearance testing instrument like Rhopoint IQ-S automatically detect the peak of the reflected light and virtually adjusting its sensor position to compensate for uneven surfaces. It also corrects haze measurement on metallic coatings by capturing compensation information from a region adjacent to the haze angle.

Besides reflection haze, measuring other visual appearance attributes like orange peel, reflected image quality and gloss contributes to a harmonious product appearance.

To learn more on visual appearance measurement or to schedule a free product demonstration, please contact us.