Konica Minolta Repair and Tech Support Services

At Konica Minolta Sensing, we pride ourselves on our ability to provide outstanding service.

For all of the details, including shipping procedures and information regarding cost, call our toll free service hotline. We are also available by fax or email. Our Calibration & Certification Laboratory look forward to hearing from you.

For pricing and details on all Konica Minolta repair and tech support packages, please call +65 6895 8681.

Konica Minolta Repair and Tech Support Services

At Konica Minolta Sensing, we pride ourselves on our ability to provide outstanding service.

For all of the details, including shipping procedures and information regarding cost, call our toll free service hotline. We are also available by fax or email. Our Calibration & Certification Laboratory look forward to hearing from you.

For pricing and details on all Konica Minolta repair and tech support packages, please call +65 6895 8681.

Our Pledge

At Konica Minolta Sensing, we set industry standards for service and support. Now, we’ve reinvented our commitment to excellent service for repairs and tech support:

Fast and On Time Repairs

Konica Minolta Sensing provides the industry’s quickest and most reliable turnaround time for service and repairs. Should a Konica Minolta repair take longer than the the amount of time which was quoted, equipment may be rented free-of-charge.

Professional & Personalized Service Experience

Unlike our competitors, Konica Minolta service centers provide incredible support for the reason that certified technicians handle all of our cases. A dedicated service technician handles each issue for the entire duration of the repair process. All technical issues are guaranteed to be resolved within a 24 hour time-slot (save for hardware problems).

Comprehensive Service & Extended Warranty Programs

We offer three levels of affordable protection. We also offer convenient rental & expedited programs: we offer rental equipment or 48-hour expedited service for those customers who unable to forego the usage of their equipment for longer periods of time.

Backed by the Konica Minolta Sensing Promise

Konica Minolta Sensing has been manufacturing state of the art light and color measuring instruments for over 20 years. Konica Minolta offers a guarentee that yo’d come to expect from our reputation. We are dedicated to our customers. Providing both exceptional quality products and unmatched service, Konica Minolta will continue to meet the needs of it’s customers, whatever those may be. This is our promise to you.

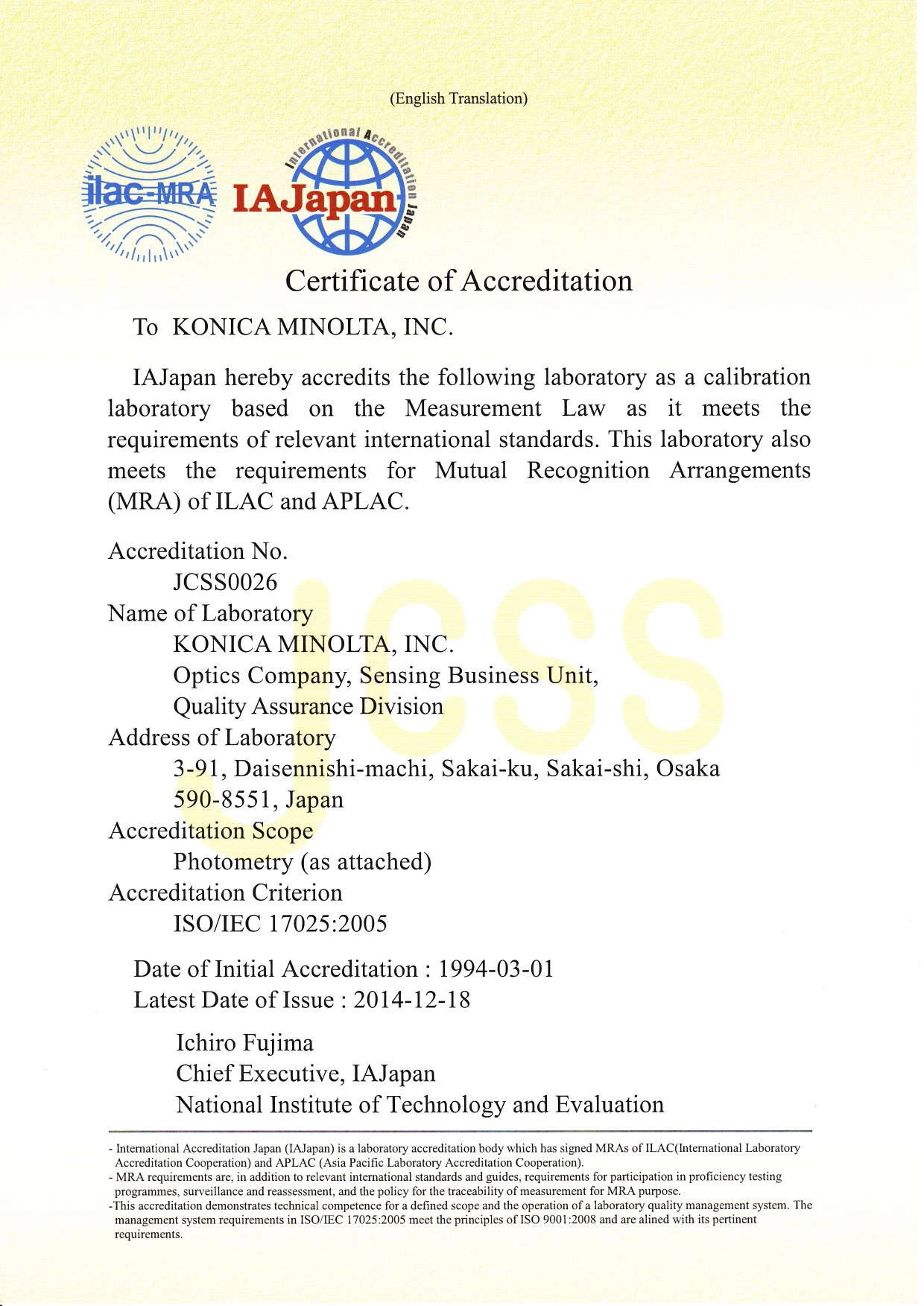

Calibration

Konica Minolta Sensing’s state of the art calibration laboratory is here to ensure that your instruments are always working at peak performance. Our highly trained technicians and specialists work to calibrate your instruments with precision; meeting national and international traceable calibration standards.

Both factory instrument calibration and daily instrument calibration are important to maintaining consistent and reliable readings from your color measurement instrument. Both calibrations must be current, and are necessary to the ensure the instruments highest performance. ‘You can’t have one without the other.’

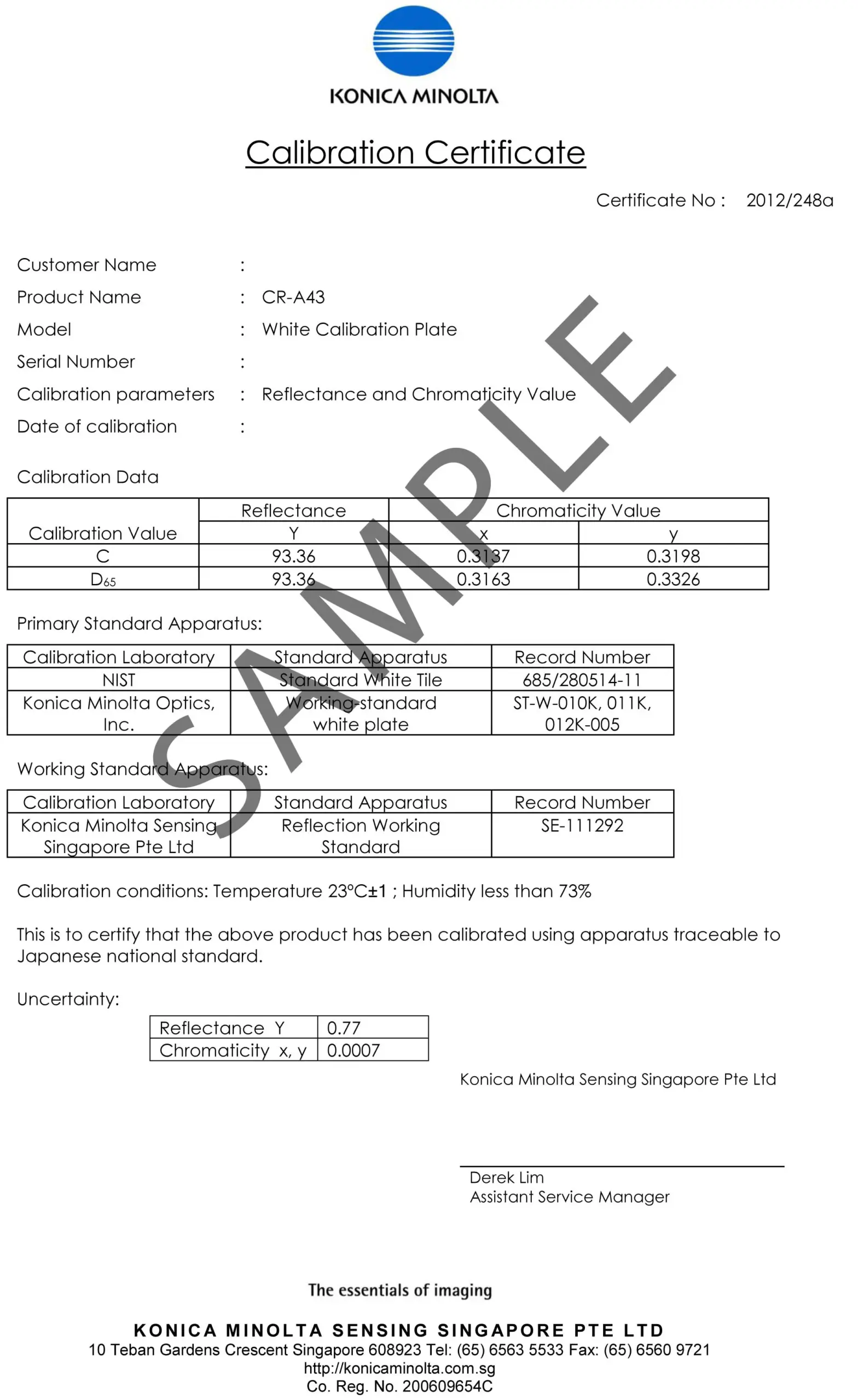

Daily calibration is a procedure that is designed for the instrument operator to bring the instrument to a known state utilizing a factory supplied reference standard of traceable values.

The procedure for daily calibration is simple and straightforward. Two measurements are taken with the instrument, one measurement of a ceramic white standard with traceable values, and one measurement of absolute black.

The measurement of the white ceramic standard must always be performed with the standard that was assigned to the respective instrument. Each white standard is serialized and therefore easily paired with the correct instrument. The absolute black measurement, referred to as a ‘zero calibration’ or ‘black trap measurement’ can be performed by utilizing a special attachment for the instrument which absorbs all light (black trap, or zero calibration box), or by taking a measurement with nothing in front of the instruments measurement port for at least 1m (open port black calibration). In either scenario the end result is the same in that no light will be reflected back into the instrument and therefore the measurement result will be of an absolute black.

Both the white standard reading and the absolute black reading are utilized by the instruments onboard processor to set the instrument to a known state of calibration.

Daily calibration of color measurement devices should be performed in the same environment and conditions as the measurements with the device will be taken. The instrument and its calibration standard should be given sufficient time to acclimatize to the environment where calibration and measurement will occur. Typically with stationary instruments a minimum interval that daily calibration should be performed is every 8 hours or every shift. However there are various cases where daily calibration should be performed more often such as:

- If the environmental conditions of temperature and humidity change. The calibration process allows the operating environment to be taken into account to provide consistent results.

- If the measurement mode of the instrument is changed, for example specular component, reflectance, transmittance, etc…

- If the aperture size of the instrument is changed.

If you have any questions on calibration interval please consult the user’s manual of the instrument or with Konica Minolta’s team of application engineers, they can recommend the optimum calibration interval based on your specific measurement requirements. Keep in mind, daily calibration only takes a matter of seconds, so when in doubt, re-calibrate!

There are several important considerations when performing daily calibration of color measurement devices, they can be summarized as:

- Ensure the white calibration tile is free from scratches, dirt, or fingerprints. Any debris or abnormality can affect the calibration of the device in question.

- Ensure the white calibration tile is seated correctly to the instruments measurement aperture. Any angular misalignment can cause variation in the measurement of the calibration standard and introduce error.

- Ensure you are utilizing the correct white calibration standard for your device.

- For black calibration utilizing a zero calibration box ensure that the zero calibration box, or black trap, is free from dust and debris.

- For black calibration utilizing an open port calibration, ensure that there is no objects in front of the instruments measurement port less than three feet, and do not place the measurement port facing toward a light source.

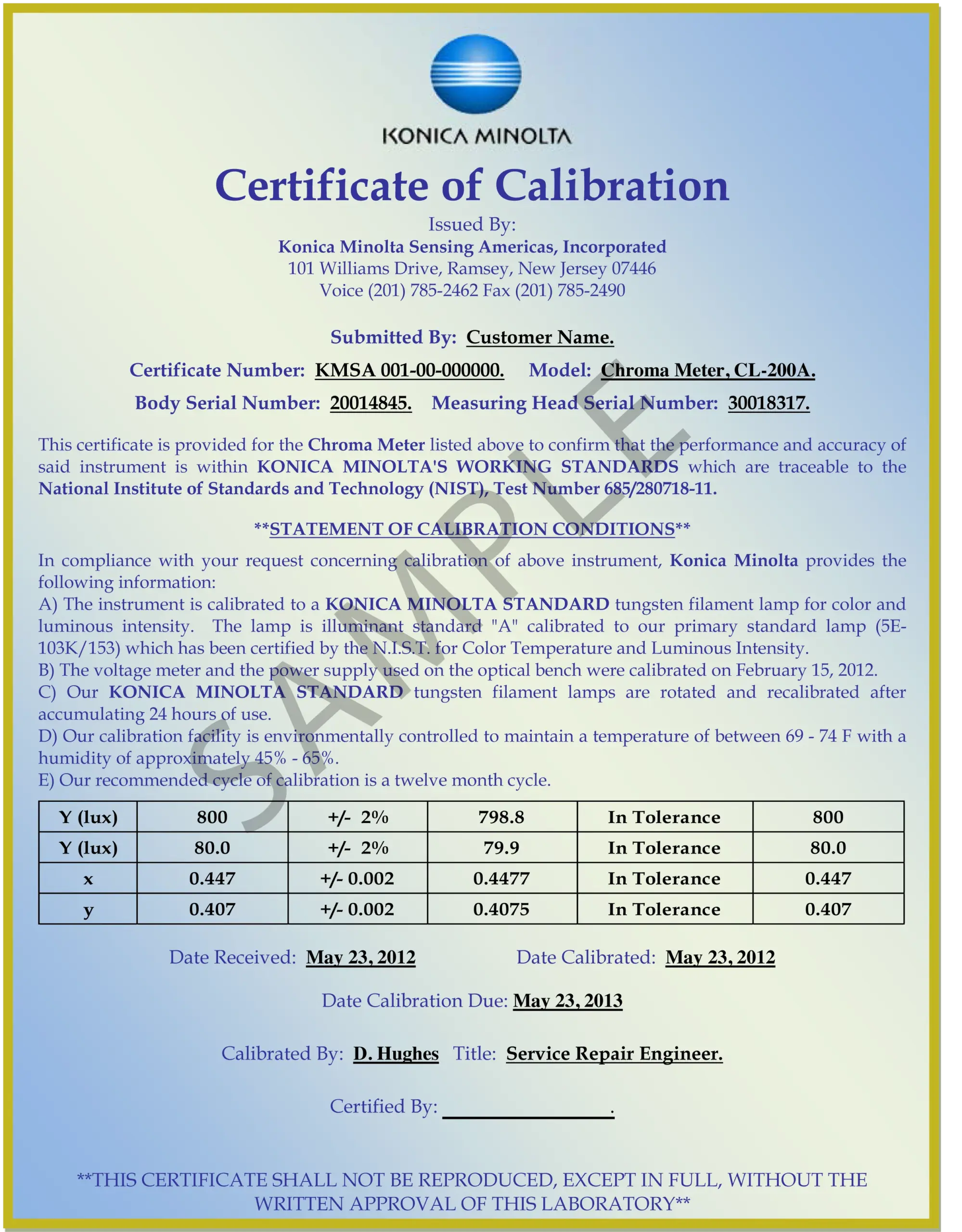

Factory calibration, also referred to as annual calibration, is a much more comprehensive testing and re-calibration of an instrument. Factory calibration is the process of adjusting the accuracy of the instrument in comparison to a master instrument and standards which meet known national or international traceable standards. Daily calibration and factory calibration share the same goal, making sure your instrument is reading accurately and repeatable. The two go hand in hand and neither can replace the other.

Every new Konica Minolta Sensing instrument ships with its factory calibration assured. This baseline factory calibration is what ensures your daily calibrations can be completed correctly and accurately. Your daily calibrations are tied to the accuracy of the instruments factory calibration. To ensure instruments will function correctly over time it is necessary that all color measurement instruments receive factory calibration on an annual basis.

- Factory calibration can only be performed by a trained and certified Konica Minolta Sensing Singapore service technician either in our state of the art calibration laboratory in Singapore, or at the instruments location by one of our field service engineers.

- Ensures the instrument meets all of the measurement specifications as it did when it was newly produced. The specifications and methods to evaluate are traceable to in house master instruments and standards which are traceable to standards organizations such as NIST, NPL, etc….

- Assess the instruments overall ability to read color through the entire spectrum both for accuracy and repeatability.

- Evaluates and if needed corrects through repair the instruments physical state, such as optics, lamps, apertures, etc…

- Recalibrates and assigns new calibration values to the white calibration tile used for daily calibration.

- Issues new traceable certificates for both the instruments factory calibration, and the standard white calibration tile.

For more FAQ Information, please click here.