Why Measure Gloss in 85°, 60°, and 20°?

Visual appearance of a product is one of the major factors in capturing consumer’s preference. Besides color, gloss is another key measurement parameter used to evaluate visual quality. Gloss is measured by quantifying the amount of light that is reflected off a surface and measurement is recorded in gloss units (GU). The higher the gloss units, the more reflective and glossy a surface is.

Like colors, perception of gloss level is subjective between different people. What may look glossy for a furniture designer may be dull for a car manufacturer. To achieve the desired gloss level accurately and consistently, the use of gloss meters is needed.

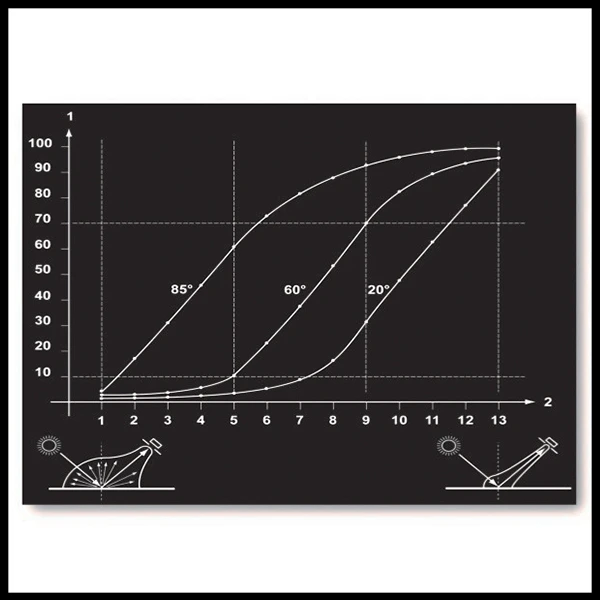

Different gloss levels reflect light differently. To accommodate a wider range of gloss and determine the true difference in gloss value, more than one measuring geometries is recommended. Many industries use the 85°/60°/20° geometries specified in ASTM D523 to measure gloss. Using 60° as the standard measurement angle, readings below 10 GU and above 70 GU are recommended to measure again using the 85° and 20° geometries respectively, to optimize measurement accuracy.

A 85°/60°/20° tri-gloss instrument like Rhopoint IQ is able to measure gloss and quantify coating-related effects such as orange peel and haze simultaneously, providing a cost-effective and time-saving solution to appearance measurement.

To learn more about gloss measurement and other appearance measurement solutions, write or call us at 6563 5533 for a free consultation.