Digital Color Management: From Manufacturing to Quality Control

Colors play a vital role in branding, product differentiation, and enhancing the customer experience. Maintaining accurate and consistent colors is particularly crucial in today’s globalized supply chain, where products are sourced, manufactured, and distributed across multiple locations. However, achieving this goal can be challenging due to the diverse production sites, which introduce variations in raw materials, manufacturing processes, and environmental conditions that affect color production. Moreover, traditional methods of color evaluation relying on visual assessments can introduce subjective biases and inconsistencies, leading to costly mistakes. As a result, manufacturers have sought alternative solutions, which is where digital color management comes into play.

Digital Color Management

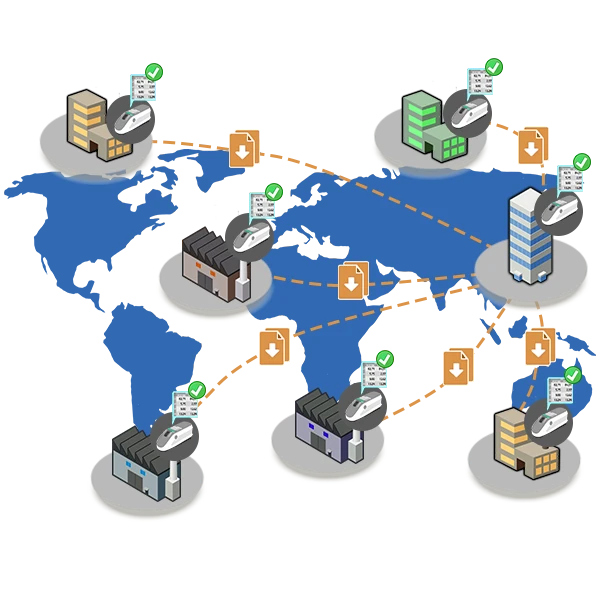

Digital color management is a meticulous and objective approach that utilizes various color measurement technologies to quantify and represent colors in a numerical and standardized manner. This enables manufacturers to effortlessly communicate color specifications across geographic locations and among different stakeholders. With the growing globalization of the manufacturing industry, this has become increasingly crucial. By implementing digital color management, manufacturers can ensure consistent product colors, regardless of production location, and effectively communicate changes in color specifications, enabling swift responses to evolving market demands.

Furthermore, digital color management reduces reliance on physical samples, resulting in significant time and resource savings while enhancing overall efficiency. Instead of relying on the conventional process of shipping physical color samples globally, stakeholders can swiftly exchange digital color data across multiple locations, reducing turnaround time and facilitating prompt adjustments if needed.

Digital Color Management Workflow Implementation

The implementation of digital color management is a multi-step process that involves the use of specialized color measurement instruments and software. The first step is creating a digital color database, which requires precise measurements of colors using spectrophotometers or colorimeters. These color measurement instruments measure and digitalize physical samples to obtain numerical representations of colors. When selecting a color measurement instrument, it is important to consider its Inter-Instrument Agreement (IIA), as this reflects the consistency of measurements among the same instruments across different locations.

With the color data, digital color standards and specifications can be established and shared with all stakeholders involved in the production process, including suppliers and production facilities. A detailed methodology should also be included alongside the digital color standard and specifications to ensure accurate and consistent color measurement across various locations. This methodology should outline the configuration of the spectrophotometers or colorimeters, including the model, geometry, standard observer, illuminant settings, and measurement mode (reflectance or transmittance). Additionally, documenting the color space, color tolerance, accessories, measurement points, instrument orientation, and the number of measurements, including the preparation and presentation of samples for measurement, will greatly contribute to maintaining consistency.

Throughout different stages of production, spectrophotometers or colorimeters can be employed to monitor and assess color accuracy. This proactive approach enables the prompt identification of any deviations from the defined color standards, minimizing the potential for color discrepancies in the final product.

Konica Minolta Digital Color Management Solutions

Konica Minolta Sensing, a trusted provider of color measurement solutions, offers a comprehensive suite of digital color management solutions to help manufacturers across various industries achieve their color goals effortlessly.

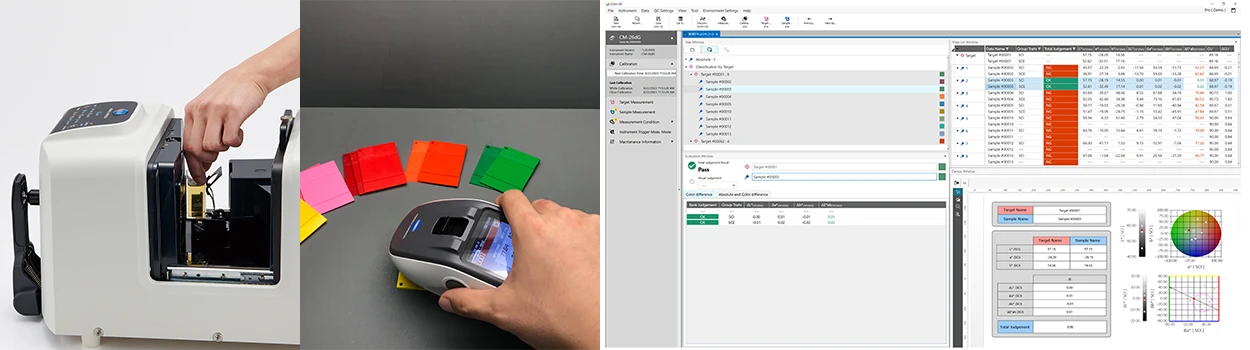

Color measurement instruments like Spectrophotometer CM-36dG and Spectrophotometer CM-26dG offer excellent IIA and are designed to provide precise and reliable color measurement, ensuring consistency in the color production process. Konica Minolta Sensing also offers user-friendly color management and quality control software like SpectraMagic NX2 for defining and sharing digital color data and standards across geographic locations, streamlining color communication, and monitoring and evaluating color accuracy during production.

Konica Minolta Digital Color Management Solutions: Spectrophotometer CM-36dG (left), Spectrophotometer CM-26dG (center), and SpectraMagic NX2 (right).

With Konica Minolta Sensing’s digital color management solutions, manufacturers can streamline their color processes, improve efficiency, reduce resource costs, and ensure consistent product colors to meet market demands. Contact us today to learn more about how we can help your company implement effective digital color management.