Automotive Exterior Evaluation: Small and Curved Metallic Painted Part

For automotive manufacturers, ensuring color consistency across all adjacent parts is not only a statement about their product quality, it is important to their brand as well. Qualifying a car is a challenging process and one such challenges would be measuring the color of parts with small or curved surface.

When attempting to measure the color of small or curved parts like shark fin antenna, door mirror and handle, their curvature often makes it difficult to properly position the instrument, giving rise to small spacing and uncovered gap which result in unreliable color data. To overcome this problem, instrument with small measuring area is necessary.

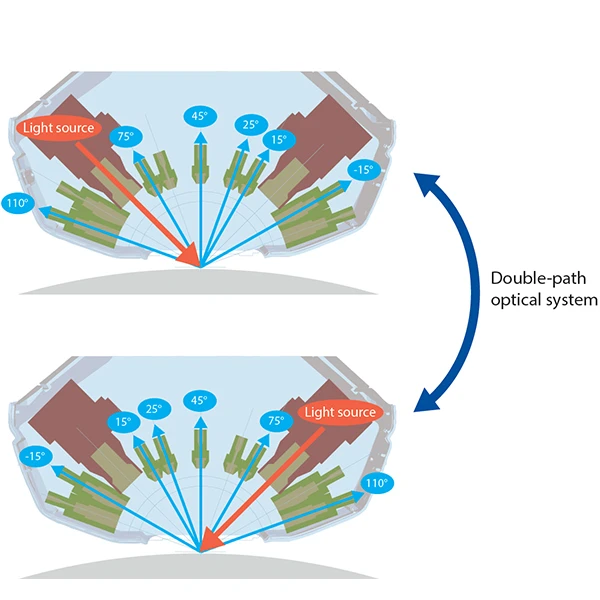

Konica Minolta Spectrophotometer CM-M6, with small measuring area of 6 mm, can easily measure metallic colors at 6 viewing angles of -15°, 15°, 25°, 45°, 75° and 110°, making it possible to fully capture the color travel of small and curved metallic painted parts.

Equipped with the patented double-path illumination system, the CM-M6 has illumination/viewing systems from two sides that ensures high measuring stability on curved surfaces (r > 300).

Check out this video to learn more about CM-M6.

Find out more on automotive color testing and measurement solutions with our advance imaging solutions for automotive industry.

Alternatively, get in touch with us for a free consultation with our color application specialists.