Improved Distinctness of Image (DOI) Measurement of High-Gloss Finishes

Many manufacturers incorporate high gloss finishing into their products, like automotive, high-end products, etc., to make them more visually appealing. When it comes to inspecting the appearance quality of their products, many manufacturers use only a simple gloss meter and struggle to evaluate their product appearance adequately.

Gloss Measurement

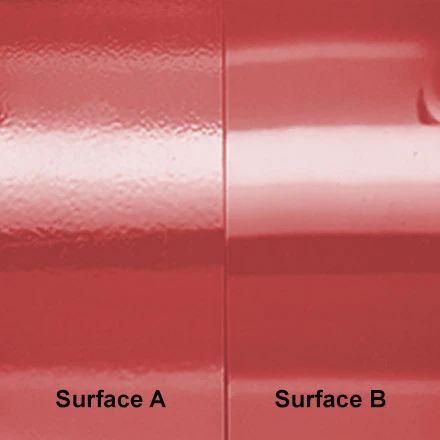

A gloss meter measures by projecting a beam of light onto the surface at a certain angle (e.g., 20°, 60°, 85°, etc.) and quantifies the reflected light at the specular angle. This measurement is expressed in terms of gloss units (GU), and the higher the GU, the more reflective the surface. However, if the surface texture has any imperfection, the reflected light will be distorted, creating a subtle scattering effect that cannot be detected by a gloss meter. As shown in figure 1, surface A and surface B have close gloss measurement readings but exhibit a vast difference in their appearance, with surface A having a texture defect known as orange peel.

| Measurement Angle | Surface A | Surface B |

| 20° Gloss | 85.6 GU | 84.0 GU |

| 60° Gloss | 95.2 GU | 91.3 GU |

| 85° Gloss | 97.3 GU | 96.6 GU |

Figure 1 – Limitation of gloss measurement

Orange peel is a textured imperfection commonly found in high gloss applications which causes reflected images on the surface to appear fuzzy or distorted, reducing a product’s overall appearance quality. Distinctness of Image (DOI) is one of the first and most commonly used parameters for evaluating orange peel.

Distinctness of image (DOI) Measurement

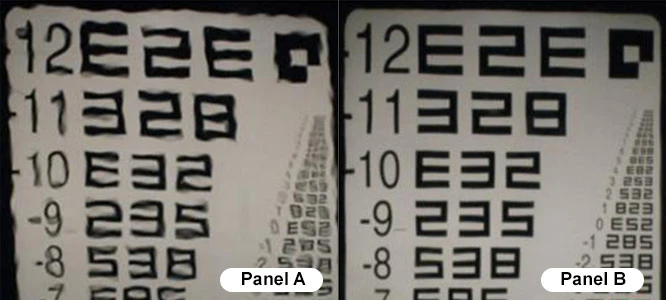

DOI is a measure of how clear a reflected image appears on a surface. DOI is measured instrumentally, and surfaces with a high DOI value would indicate sharp reflected images and a low amount of orange peel. However, the shortcoming of DOI measurement is that it becomes less sensitive as the amount of orange peel reduces. For example, in figure 2, the visual difference between panel A and panel B is not reflected in proportion between their DOI measurement readings.

| Panel A | Panel B | |

| DOI | 96.2 | 98.7 |

Figure 2 – Limitation of DOI measurement

Improved DOI – Reflected Image Quality (RIQ) Measurement

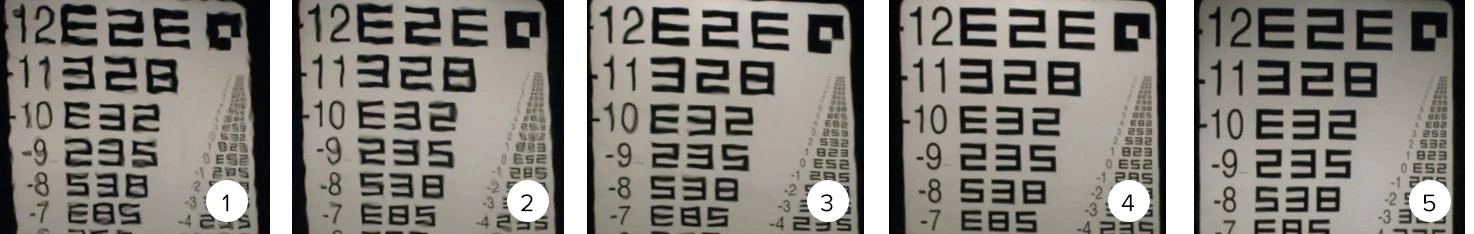

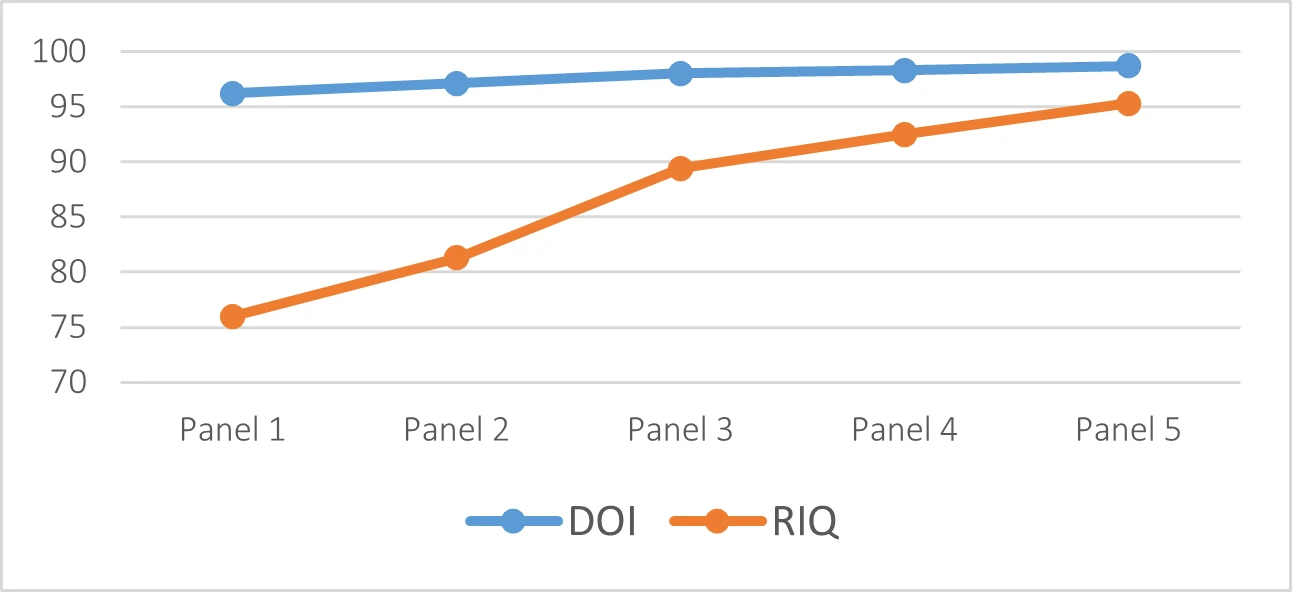

Measurements that are better correlated with visuals can be achieved with Reflected Image Quality (RIQ). An improved version of DOI, RIQ uses a shorter sensing distance around the specular angle and measures the reflected light, including distortion, providing a better resolution response than DOI. Figure 3 shows an example of five panels marked with orange peel measured using both DOI and RIQ.

Figure 3 – Higher resolution response from RIQ measurement

As seen above, RIQ is more sensitive as compared to DOI when the amount of orange peel reduces, showing better agreement between their measurements and visual appearance.

Appearance Meter Rhopoint IQ-S

Rhopoint IQ-S is an all-purpose appearance meter that can simultaneously measure tri-gloss (20°, 60°, and 85°), DOI (orange peel), RIQ, and reflection haze. In addition, goniophotometric curves can also be obtained for a deeper understanding of the specular reflectance of a surface.

Check out this video to find out more about Rhopoint IQ-S or appearance measurement.

Need help measuring your product appearance? Contact our specialists for a free consultation now.