Nuts Quality and Safety Inspection With Hyperspectral Imaging

Nuts products like almonds, peanuts, walnuts, cashew, etc., must undergo quality and safety inspection to meet consumers’ expectations while being safe for consumption. This means sorting nuts into different grades based on their shape, size, and color or identifying and removing foreign objects (e.g., shells, insects, plastics, etc.) and contaminated or out-of-specification nuts.

There are a few different ways that quality and safety inspections can be carried out on nuts. The traditional way is to visually inspect the nuts for any signs of contamination, out-of-specification, foreign objects, etc. However, because of their close resemblance, inspecting nuts visually at high speed is extremely demanding. In recent years, imaging-based systems have been deployed as a fast, non-destructive, and high throughput alternative to inspect the quality and safety of food products. The imaging systems used were typically based on the conventional red, green, and blue (RGB) color cameras. However, similar to our eyes, the RGB camera uses only three color bands – red, green, and blue – their identification capability is limited, especially when it comes to inspecting nuts. Most nuts have a minimal color or shade variation between them or their shells, so it can be challenging to differentiate them reliably with an RGB camera. This can result in additional time needed to reinspect the rejects to recover yield. An alternative to RGB cameras is hyperspectral imaging (HSI) cameras.

Hyperspectral Imaging (HSI)

Instead of the three visible color bands, HSI cameras capture information from hundreds of thousands of contiguous and narrow bands across a particular section of the electromagnetic spectrum, like visible and near-infrared (VNIR), short-wave infrared (SWIR), etc. Hence, HSI cameras can see much finer details from the nuts or their shells, providing a more accurate and reliable way of inspecting the quality and safety of nuts.

Figure 1 – Differentiating walnuts from their shells with HSI. Image courtesy of SPECIM, SPECTRAL IMAGING LTD.

The use of HSI cameras in nuts quality and safety assessment is well documented in many research. For instance, Mishra et al. (2022) demonstrated the effectiveness of using a SWIR HSI camera in their study to detect aflatoxin B1 in almonds. Faqeerzada et al. (2020) used a near-infrared (NIR) HSI camera to distinguish the almonds from apricot kernels, a common adulterant of almonds. HSI cameras were used by Nakariyakul and Casasent (2011) in their study to differentiate internally damaged almonds from normal ones. Jiang et al. (2007) combine HSI and fluorescence imaging technologies to differentiate walnut meat from its shells.

Specim Hyperspectral Cameras

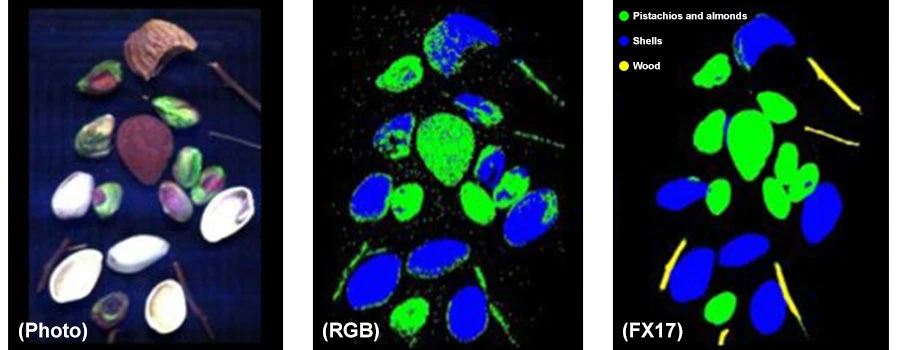

Specim, a leading HSI solutions provider, offers a wide selection of HSI cameras, covering the VNIR spectral region to the long-wavelength infrared spectral region. When it comes to inspecting the quality and safety of nuts, the Specim FX series, notably the Specim FX10 hyperspectral camera and Specim FX17 hyperspectral camera, with 224 spectral bands and high spatial resolutions, enable easy characterization and identification of nuts and contaminants or foreign objects. As shown in Figure 2, the Specim FX17 hyperspectral camera can differentiate the pistachios and almonds from their shells and foreign objects better than an RGB camera.

Figure 2 – Imaging data from RGB camera (center) and Specim FX17 hyperspectral camera (right). Image courtesy of SPECIM, SPECTRAL IMAGING LTD.

The Specim FX10 and the Specim FX17 hyperspectral cameras come with high frame rates that can meet the process line speeds of several meters per second, providing the speed required for accurate high-speed nuts inspection. Watch this video to learn more about the Specim FX series hyperspectral cameras.

Specim FX series hyperspectral cameras are widely used in many food sorting applications. Read how Strelen Control Systems GmbH incorporated the Specim FX10 into their sorting machine to help food producers sort nuts with precision and speed while having the flexibility to inspect different types of nuts without the need to retrofit or replace any components in the machine.

Wish to learn more about HSI? Or perhaps need help finding the right hyperspectral cameras and solutions for your applications? Talk to our specialists for a free consultation now.