Acrylic Plastics Color Measurement Made Simple With Spectrophotometer

Acrylic plastics, or polymethyl methacrylate (PMMA), have been used in a wide range of products, such as furniture, windows, art decor, and so on. Their outstanding physical properties and availability in various colors and transparency make them valuable for these purposes. Acrylic plastics must go through extensive quality control testing throughout manufacturing to assure consistent quality standards, and color measurement is critical when it comes to evaluating their aesthetic qualities like color.

Visual Color Evaluation of Acrylic Plastics

While color can be evaluated visually, it has several drawbacks. One is that it can be subjective, depending on the individual’s perception. What may look like one color to one person may be seen as a different color by someone else. Furthermore, the surrounding lighting and sample size can also influence how a color is perceived.

Spectrophotometer Color Measurement of Acrylic Plastics

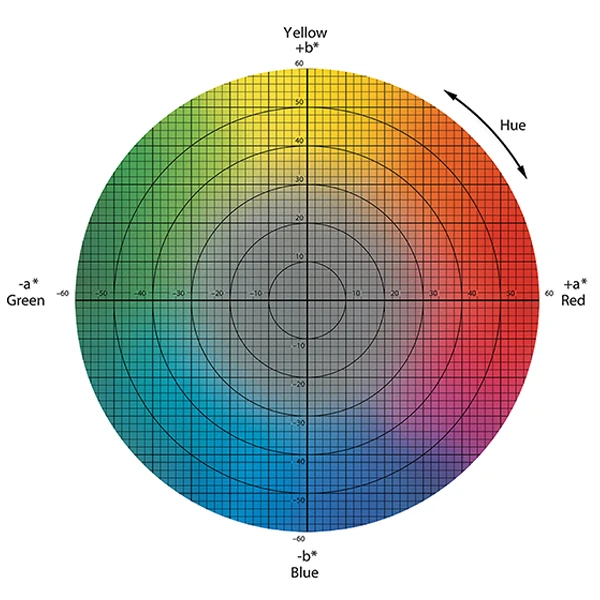

A quantitative description of acrylic plastic color can be achieved using a spectrophotometer. It works by measuring how much light is absorbed or reflected by the plastic, which then calculates and outputs it into numerical values in a variety of color spaces/indices such as CIE L*a*b*, yellowness index, etc. This helps eliminate subjectivity across individuals, enabling accurate and consistent measurement, management, communication of color across the whole acrylic plastic manufacturing process.

Reflectance and Transmittance Color Measurement Mode

A spectrophotometer can measure color in reflectance measurement mode, transmittance measurement mode, or even both. It is critical to utilize the proper measurement mode for your intended use to ensure that the resulting color data are accurate and reliable. Deciding which to use depends on the transparency of your sample. For solid or opaque colored acrylic plastic, reflectance color measurement is typically preferable, whereas transmittance color measurement is best for transparent or translucent colored acrylic plastic.

Establishing Color Tolerance

Setting up a color quality control program to verify that the color you specified is correct starts with establishing a color acceptability strategy. Setting a color tolerance is one of the most important elements of any successful color quality control program. Color tolerance is the maximum distance between a sample and a reference point on which colors may vary. Use either the Delta E00 or the CMC tolerancing method for better color agreement between spectrophotometer readings and visual inspections.

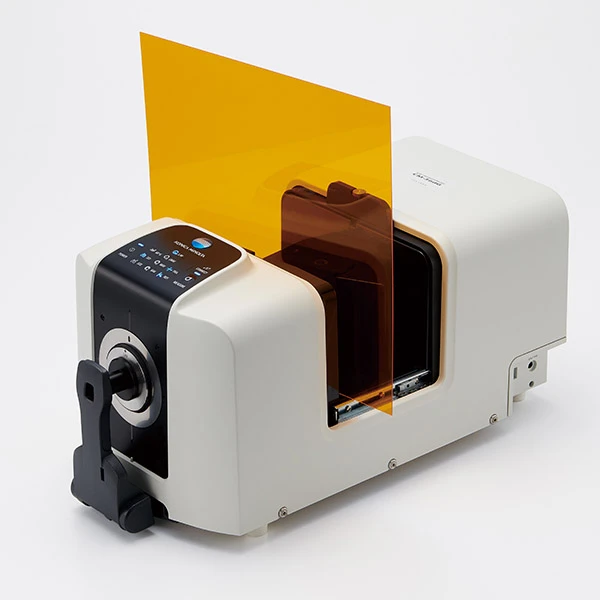

Spectrophotometer CM-36dG

Konica Minolta Spectrophotometer CM-36dG, a highly accurate and flexible color measurement instrument, can perform both reflectance and transmittance color measurement, providing an easy, accurate, and reliable color measurement of acrylic plastic ranging from opaque to transparent.

Close color measurement readings can be expected between multiple CM-36dG units with its tight inter-instrument agreement (IIA) of ∆E*ab< 0.12 (average of BCRA 12 Tiles), and this can help minimize color inconsistency across the manufacturing process or supply chain. The CM-36dG is also equipped with a 60° gloss sensor, allowing both color and gloss to be measured simultaneously. When used with SpectraMagic NX Pro Software, correlated haze can be measured as well.

Watch this video to find out more about the innovative CM-36dG and its advanced features and functions.

Need help measuring the color of your acrylic plastics or require assistance in setting up a color quality control program? Contact our color specialists for a free consultation now.