From Farm to Table: Accurate Color Measurement in the Food Industry

Food color measurement is a critical aspect of quality control and product development in the food industry. The color of food not only influences consumer perception and acceptance but also serves as an important indicator of freshness, ripeness, and potential spoilage. For instance, vibrant colors in fruits and vegetables often signal optimal ripeness, while dull or off colors can suggest that a product may be past its prime. Additionally, maintaining consistent color across batches can help build credibility among consumers, as people often associate certain colors with specific flavors and quality levels. Through precise color measurement, food manufacturers can ensure their products meet the industry standards and expectations of their customers.

Methods of Food Color Measurement

There are several methods to measure food color, each varying in precision. The most basic method is visual assessment, which relies on the human eye to evaluate color. While this approach is quick and inexpensive, it is highly subjective and can lead to inconsistencies due to varying lighting conditions and differences in individual perception.

A more accurate approach is through the use of color measurement instruments. These instruments, such as colorimeters or spectrophotometers, use scientific principles to quantify colors and provide objective measurements. They are commonly used in the food industry to ensure consistency in product appearance and quality.

Colorimeters measure color by analyzing light reflected off a surface. They operate using three color filters—typically red, green, and blue—to mimic the way the human eye perceives color. These color measurement instruments offer more reliable and quantifiable data than visual assessments, significantly reducing the margin for error. Spectrophotometers elevate accuracy even further by measuring the spectral reflectance or transmittance of a sample across the visible spectrum. These color measurement instruments can detect subtle color variations, providing detailed and precise color information essential for quality control.

Given that food comes in various forms, each type necessitates a specific color measurement mode to ensure reliable and accurate data. The form of the food—whether solid, liquid, opaque, or transparent—determines whether reflectance or transmittance is the appropriate color measurement method.

Reflectance color measurement involves shining light onto the surface of a food product and measuring the light reflected from the surface. This method is widely used for solid and opaque food products like fruits, vegetables, grains, and baked goods. Conversely, transmittance color measurement involves passing light through a food product and measuring the amount of light that emerges on the other side. This method is suitable for transparent or semi-transparent food items like liquids, gels, or translucent solids (e.g., beverages, juices, oils, jams, etc.).

Konica Minolta Color Measurement Solutions for the Food Industry

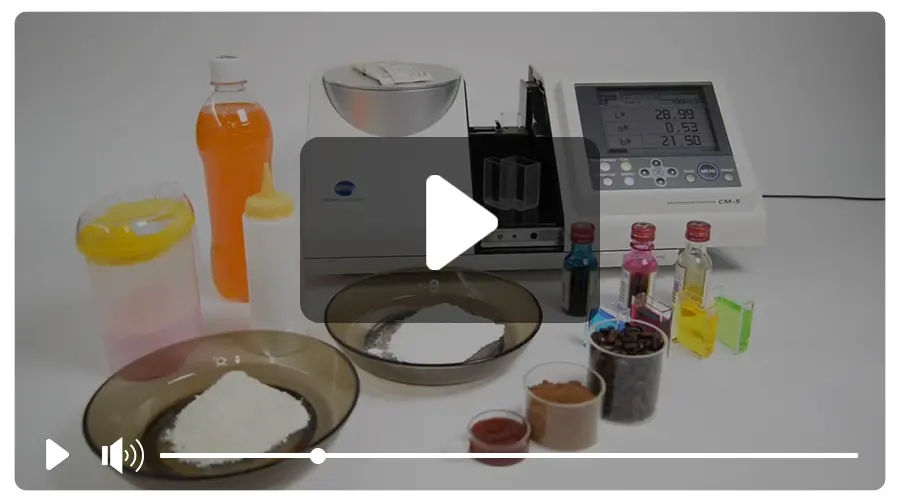

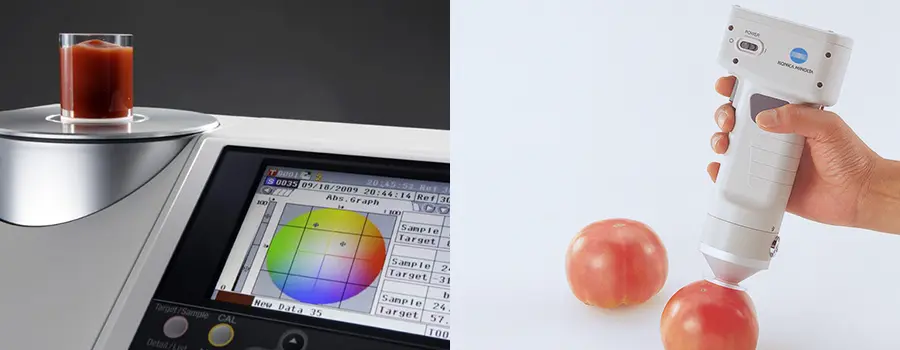

Spectrophotometer CM-5 (left) and Chroma Meter CR-400 (right)

Konica Minolta Sensing, a leading measurement solutions provider, offers a comprehensive range of color measurement instruments specifically designed for the food industry. Among these are the portable colorimeters, the Chroma Meter CR-400 and CR-410, ideal for quick, on-site color assessments. For more versatile applications, the benchtop Spectrophotometer CM-5 offers both reflectance and transmittance color measurement capabilities, effectively accommodating food products in various forms—whether solids, powders, pastes, or liquids. Check out the CR-400/CR-410 and CM-5 videos to learn more about their functions in greater detail.

WATCH VIDEO

In addition to color measurement, Konica Minolta Sensing offers hyperspectral imaging cameras designed for in-depth food quality analysis and inspection. These cameras capture and analyze the spectral data of food products, allowing for the detection of defects, foreign objects, and other quality issues that are often invisible to the human eye. Additionally, hyperspectral imaging provides a comprehensive understanding of product characteristics such as moisture content, fat content, and ripeness, making it invaluable for various food research and development applications. Head over to the agriculture and food measurement solutions section to explore Konica Minolta Sensing’s extensive range of measurement solutions widely used in the food industry.

Are you struggling to find suitable colorimeters/spectrophotometers or measurement solutions to ensure the highest quality in your food products or research applications? Our experts are here to help—reach out to us now for a free consultation.