Importance of Imaging System Sensor Pixels in Measuring High-Resolution Displays

The trend in displays has moved relentlessly towards higher-resolution technologies, like OLED and microLED, with a large amount of small and densely packed pixels. These high-resolution displays devices are typically expensive, and consumers expect high quality and performance in return.

To ensure their display devices deliver a flawless visual experience and are defect-free, display manufacturers have long relied on imaging systems to inspect for uniformity issues and defects like dead pixels or stuck on/off. When it comes to display inspection, the term pixels can often be referring to either the display pixels or the image sensor pixels.

Display pixel refers to the smallest physical points in a display, and the resolution of a display indicates the number of pixels contained within. A display measuring 7680 pixels horizontally and 4320 pixels vertically equate to having a total of 33,177,600 pixels. The more pixels, the higher the resolution and the better the quality of the displayed images.

An image sensor consists of a two-dimensional grid of small light-sensing elements known as image sensor pixels. The number of pixels on the grid represents the resolution of the imaging camera. These sensor pixels capture the light emitted by the display pixels and convert them into information to measure brightness (luminance) value and chromaticity (using color filters).

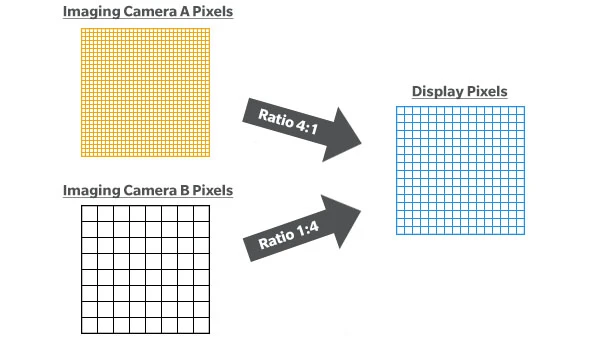

A high-resolution imaging camera with a higher sensor pixel count than a display can effectively measure and capture the data of each display pixel more accurately and at a much faster speed. As shown in the illustration below, imaging camera A can capture the data of each display pixel as it has more pixels than the display. For imaging camera B, which has lesser pixels than the display, the amount of detail captured is lesser as each sensor pixel can only capture data from multiple display pixels. To capture the data of each display pixel, we will need to segment the display into smaller evaluation areas to accommodate the image sensor resolution of imaging camera B.

Illustrative example of imaging camera sensor pixels and display pixels

When it comes to evaluating high-resolution and pixel-dense displays, imaging cameras like Radiant’s ProMetric® Y series Imaging Photometers and I series Imaging Colorimeters, with resolutions of up to 61 MP, can measure display pixels, down to the subpixel level, with ease.

The ProMetric® imaging camera, with a scientific-grade image sensor optimized for low image noise, combines high resolution and dynamic range, enabling measurement of high-resolution and pixel-dense displays with repeatable accuracy. Combining with measurement techniques like the fractional pixel method (US Patent 10971044) and the spaced-pixel method (US Patent 9135851), users can capture an entire high-resolution display in a single image for measurement at the pace of their production lines.

The ProMetric® imaging camera, with a scientific-grade image sensor optimized for low image noise, combines high resolution and dynamic range, enabling measurement of high-resolution and pixel-dense displays with repeatable accuracy. Combining with measurement techniques like the fractional pixel method (US Patent 10971044) and the spaced-pixel method (US Patent 9135851), users can capture an entire high-resolution display in a single image for measurement at the pace of their production lines.

Konica Minolta with group companies (Radiant Vision Systems and Instrument Systems) offers a wide range of instruments well suited for measuring various types of displays. Explore our wide selection of display testing instruments and solutions to find out more.

Need help testing and inspecting your display? or require assistance in finding the right instruments or solutions? Contact our specialists for a free consultation now.