Measuring the Color of Soap Bars

Color is one of the important sensory elements of a soap bar. There is a psychological effect that consumers will perceive that something is wrong with the soap bar if its color doesn’t match its scent. In the manufacturing of soap bars, manufacturers add their preferred color pigments, fragrances, and additives with the basic soap noodles to manufacture their own brands of soap bars. The color of these raw ingredients can have a huge influence on the final color quality of the soap bars. To ensure the intended color are produced accurately and consistently, color evaluation and control is necessary.

Raw materials such as scented oils, carrier oils and color stabilizers if not controlled or standardized can affect the final color. Color instruments can help monitor and qualify the various materials to ensure consistency. Such research works will help to minimize or eliminate errors during manufacturing process.

Though the color instrument is generally used as a quality control tool, it is can also be used as a tool for process study and control. Saponification and purification processes can be studied with the processed products and conduct the necessary evaluation using the color instrument.

Color evaluation can be done either visually or with a spectrophotometer. Visual evaluation is subjective as color perception varies between individuals. Furthermore, factors such as the lighting conditions and size of the sample can influence color judgement. On the contrary, a spectrophotometer can provide a fast, consistent, and objective evaluation of color.

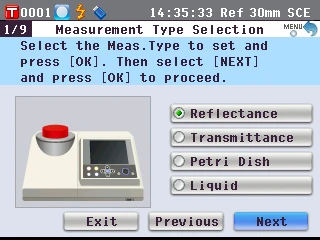

With a spectrophotometer, color tolerance can be established to help control the color of soap bar effectively. During the raw material inspection, the color of raw materials can first be verified and studied in relation to the final soap bar color. As the raw materials can come in various forms, from solid to liquid, and opaque to translucent, selecting the appropriate measurement mode (e.g., reflectance or transmittance) helps ensure the color data obtained are reliable. During the final quality inspection, color check can be performed on the final soap bar to determine if their color falls within the intended tolerance range and if corrective action is required.

When attempting to measure and control the color of soap bar, a versatile color measurement instruments like Spectrophotometer CM-5 would be helpful. The CM-5, equipped with a top-port and transmission chamber, can handle various types of samples, providing a cost-effective measurement solution. A wide selection of CM-5 accessories such as petri dish and cell are also available to help soap bar manufacturers simplify their measurement process.

Check out the CM-5 videos to find out more.

Need help implementing color management into your workflow? Get in touch with our color specialists and let us help you find the right methodology and instruments for your measurement needs.