Automating Tomato Seed Germination Prediction with Hyperspectral Imaging

In the agriculture and seed industry, ensuring that only viable seeds are planted is crucial for achieving strong germination rates and promoting healthy crop establishment. The challenge, however, is that the viable and non-viable tomato seeds often look identical to the human eye. Traditionally, producers have relied on manual inspection or destructive germination tests to evaluate seed quality. These methods are slow, labor-intensive, and prone to sampling errors, limiting both efficiency and accuracy.

As the industry moves toward precision agriculture and data-driven quality control, there is a growing demand for a faster, non-destructive, and more reliable solution — and this is where hyperspectral imaging (HSI) provides a breakthrough.

Hyperspectral Imaging: A Non-Destructive Solution for Seed Sorting

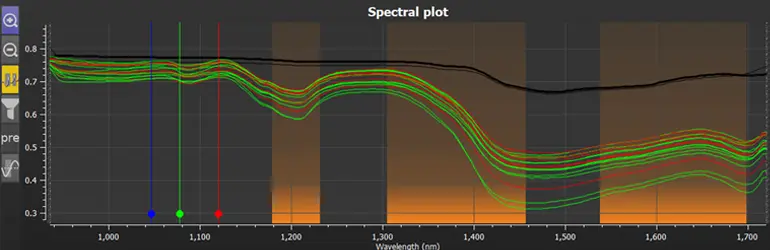

HSI offers a powerful alternative to traditional testing by leveraging advanced optical sensing to reveal details invisible to human vision. Furthermore, unlike conventional imaging cameras that capture only three broad bands of light—red, green, and blue, an HSI system collects hundreds of narrow wavelength bands across the visible and near-infrared spectrum. This high-resolution spectral information allows each seed to be characterized by a unique spectral signature, reflecting its internal chemical composition.

For tomato seeds, specific near-infrared wavelengths are strongly associated with moisture, proteins, and carbohydrates—key biochemical indicators of viability. By analyzing these subtle spectral patterns, HSI can distinguish seeds with the profile of a strong germinator from those likely to fail. Because the process is non-contact, non-destructive, and real-time, it can be seamlessly integrated into seed sorting lines.

For tomato seeds, specific near-infrared wavelengths are strongly associated with moisture, proteins, and carbohydrates—key biochemical indicators of viability. By analyzing these subtle spectral patterns, HSI can distinguish seeds with the profile of a strong germinator from those likely to fail. Because the process is non-contact, non-destructive, and real-time, it can be seamlessly integrated into seed sorting lines.

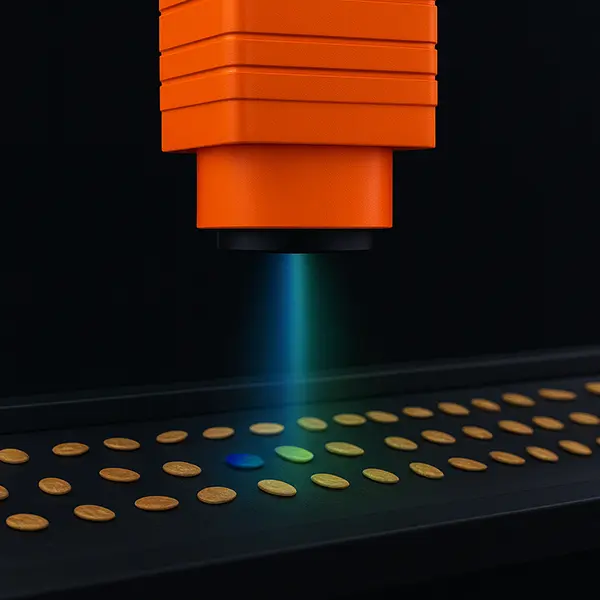

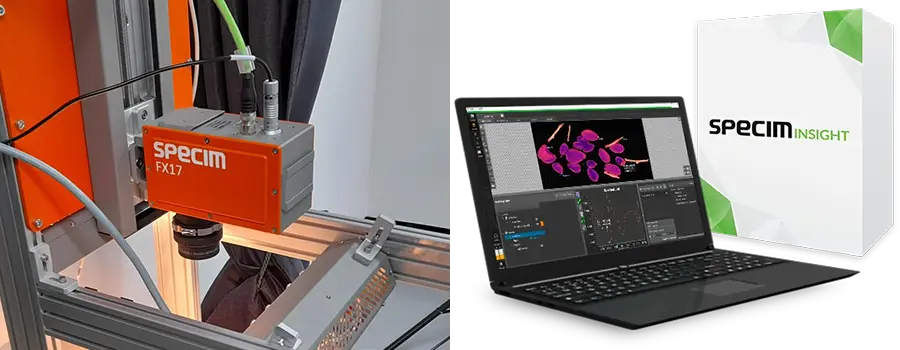

Enabling this capability is the Specim FX17e hyperspectral camera, a high-speed imaging sensor that covers the 900–1700 nm range, where critical seed biochemicals can be detected. Paired with Specim’s Lumo software for data acquisition and SpecimINSIGHT (version 1.3.72) for spectral processing and classification, these solutions form an integrated HSI system for real-time, automated seed analysis. As tomato seeds pass under the camera, the system instantly evaluates each spectrum—delivering accurate, real-time classification without damaging or touching the seeds.

Proof of Concept: Distinguishing Viable from Non-Viable Tomato Seeds

Proof of Concept: Distinguishing Viable from Non-Viable Tomato Seeds

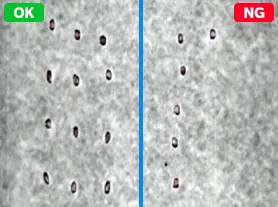

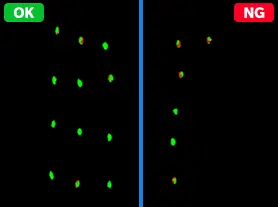

To validate this approach, a proof-of-concept trial was conducted using the integrated Specim FX17e HSI system. Tomato seeds were scanned and automatically classified as viable or non-viable, even though both groups appeared identical to the naked eye. The HSI system achieved a clear separation between the two categories, demonstrating the effectiveness of spectral analysis for seed viability testing.

Results were visualized through false-color classification images, where viable seeds appeared in green and non-viable seeds in red. In particular, the classification was not performed manually but generated by the HSI system’s trained model, providing repeatable and objective assessments. The analysis further showed that spectral fingerprints of water, proteins, and carbohydrates are strong predictors of germination potential.

These spectral fingerprints can be traced to critical near-infrared regions at 1160–1170 nm, 1380–1397 nm, 1647–1666 nm, 1860–1884 nm, and 1915–1940 nm. These wavelength bands correspond to the molecular vibrations of water, protein-bound compounds, and carbohydrates—biochemical markers that distinguish healthy, viable seeds from weaker, non-viable ones.

Transforming Seed Quality Control with Automation

Introducing HSI into seed processing unlocks new levels of efficiency and consistency. Some of the key benefits include:

- Non-destructive, real-time inspection: Seeds can be analyzed on a conveyor without being damaged, ensuring 100% inspection instead of small sample tests.

- Accurate classification of viable vs. non-viable seeds: Machine-learning models identify seeds based on spectral fingerprints, reducing reliance on subjective human judgment.

- Improved consistency: Automated sorting applies the same standard to every seed, ensuring higher germination rates and more uniform crop establishment.

- Reduced manual labor: The technology minimizes tedious hand sorting and reduces errors caused by fatigue.

- Integration-ready: HSI classification outputs can be seamlessly connected to automated sorting mechanisms, enabling the development of fully automated seed grading systems.

Specim Hyperspectral Imaging Solutions for the Agriculture Industry

Specim FX17e hyperspectral camera and SpecimINSIGHT

Specim, part of Konica Minolta Group, delivers advanced HSI solutions that are transforming quality control in agriculture. The combination of the Specim FX17e hyperspectral camera, SpecimINSIGHT, and Specim’s Lumo software creates a powerful, integrated platform for real-time, non-destructive seed analysis. By capturing detailed spectral information invisible to the human eye, this system enables 100% inspection, ensuring only viable tomato seeds progress to planting or sales. The result is higher germination success, reduced waste, and more efficient seed handling.

Beyond agriculture, Konica Minolta Sensing and Specim solutions have also found proven applications in food safety, pharmaceuticals, and recycling, reinforcing the reliability and scalability of Specim’s hyperspectral imaging solutions across multiple industries.

Contact us today to learn how our hyperspectral imaging solutions—powered by the Specim FX17e, Lumo, and SpecimINSIGHT—can revolutionize your seed quality control and drive precision agriculture forward.