Display Metrology Solutions for High-Speed Production-Line Inspection

Display technology is an essential component of today’s digital-driven world, providing a crucial link between users and their devices and products like smartphones, touchscreen display panels in automotive, etc. Display must undergo rigorous evaluation and inspection, from R&D to quality control, to ensure they are consistent with the design goals and meet the required standards for performance and reliability. Accurate and efficient evaluation and inspection can be achieved with display metrology, a scientific approach that provides objective display performance indicators through measurement data. This involves using metrology instruments or system to measure the different aspects of display performance, such as brightness, color, gamut, contrast, uniformity, defects, viewing angle, etc.

Display Metrology Instruments

A wide range of display metrology instruments is available today to support display manufacturers in characterizing and inspecting the performance of their displays. Conventional display metrology instruments like spot meters and spectroradiometers are incredibly precise when it comes to capturing luminance and chromaticity values. However, these instruments are more suited within the R&D phase (e.g., defining performance specifications for display) rather than high-speed quality control inspection, as they can only measure one spot (position) at a time. Also, these instruments generally lack the integration capability to connect with an automated system.

Image-Based Measurement System

An alternative approach to production-line display inspection is the use of imaging systems. They can capture and evaluate the entire display panel area, meeting the speed and high-volume throughput demands of inspecting display on the production line. There are several imaging systems available, and their capability depends on the type of camera used within the system. An imaging system that uses a machine vision camera can detect display defects at high speed but has limitations in the display metrology aspect. Most machine vision cameras lack the resolution required to evaluate pixel-dense displays and rely on contrast (black and white images) to detect defects in the display. For those machine vision cameras that are capable of chromaticity measurement through a color filter at the front of the sensor (e.g., Bayer Pattern filter, etc.), they do not provide absolute (CIE) color measurement. Additional custom calibration is also required to align their spectral response to the CIE color-matching functions to replicate our eye’s perception of color and light.

Display Metrology for Production

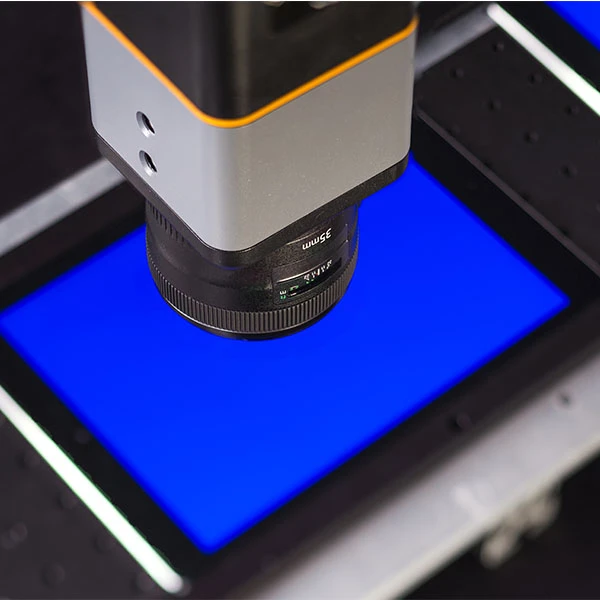

Radiant Vision Systems ProMetric® I imaging colorimeter, a metrology solution that combines scientific measurement with imaging, is capable of capturing accurate CIE-matched values for luminance and chromaticity while providing defect detection like mura, dead pixels, etc. With a built-in tristimulus color filter, the spectral response of the ProMetric® I imaging colorimeter closely matches the CIE color-matching functions, providing color accuracy as perceived by a human observer. Equipped with a scientific-grade image sensor that offers a resolution of up to 61 megapixels (MP), the ProMetric® I imaging colorimeter offers high-resolution imaging capability that can apply more sensor pixels per display pixel, increasing the amount of information captured. The ProMetric® I imaging colorimeter is supported by various camera lenses and software like TrueTest™ that form the ultimate combination of scientific metrology and machine vision efficiency for display testing. Check out this on-demand webinar to learn more about Radiant Vision Systems display metrology solutions for display production automated visual inspection.

Characterization and inspection of displays in lab and production line with ProMetric® I imaging colorimeter.

Need help finding the right instruments or solutions to characterize or inspect your display performance? Get in touch with our specialists for a free consultation now.