Understanding Color Management Workflow in Printing

Color is a vital element and is key to profitability in the printing industry. To achieve better color and more consistent prints, color management is necessary. All devices (e.g., scanners, digital cameras, monitors, printers, etc.) used within the workflow reproduce colors differently. Establishing a color-managed workflow can ensure color, from input to output and between devices, matches as closely as possible. The whole process of color management can be neatly defined into consistency, calibration, characterization, and conversion.

Consistency

A good color workflow requires consistency in every device within the workflow. A display monitor must be able to reproduce consistent color while the color output from a printer must also be consistent.

Calibration

The first step towards good color management is calibration. The printer color output will drift over time, even when using the same ink or toner. Likewise, a monitor’s color accuracy will drift or fluctuate with usage and time. All devices that contribute to the workflow should be calibrated, and this involves establishing certain known starting condition that allows the devices to return to calibrated state if their accuracy drifted. For printers, daily re-calibration is recommended to ensure the color capability of the printers are optimized.

Characterization

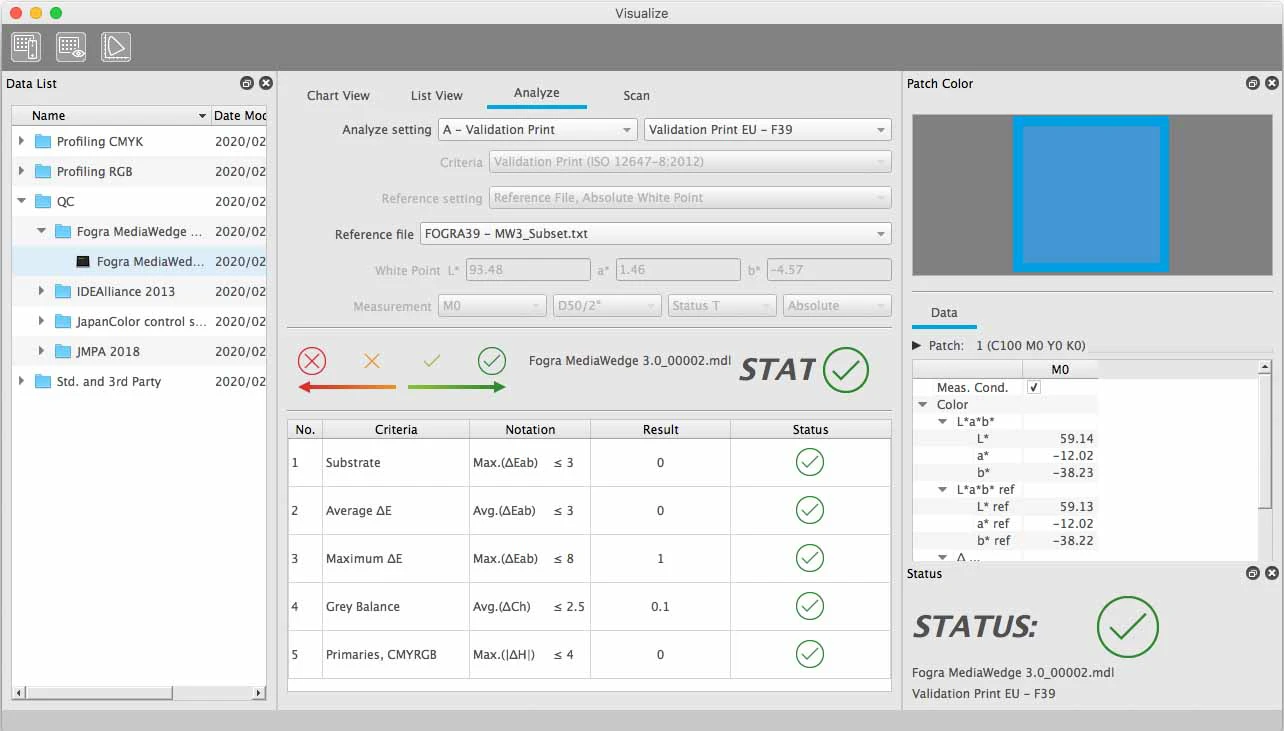

After the devices are calibrated, their color reproduction characteristics are determined in the process known as characterization or profiling. To characterize a monitor, a series of RGB, with known values, are flashed on the screen and measured using a color measurement instrument. For printer characterization, a test chart with multiple color samples is printed and measured with the color measurement instrument.

Next, the color data measured is compared with the sample colors and used to create an ICC profile. The ICC profile is a set of data that characterizes all the colors (color space) the devices can capture, display, or print To create an ICC profile, a software with color management module (CMM) that features ICC profile creation function and a standardized color chart like the IT8.7/4 or ECI2002 is required.

Conversion

After calibration and characterization, the profiles can then be used to print or display images. However, not all device uses the same color systems (RGB or CMYK) to create color, and a conversion process is needed to convert images from one color systems to another. For instance, a monitor-to-printer requires the images to be converted from the monitor RGB color system via its profile into LAB color space and then into the appropriate CMYK color system via the printer profile.

MYIRO Color Management System

When it comes to managing the color workflow, the MYIRO color management system provides a complete and affordable solution to better color and more consistent prints. The MYIRO-1, a handheld spectrophotometer, is capable of scan and spot measurement on printed color, as well as ambient light (with optional ambient light adapter) and display measurement. When used together with Color Management Software MYIROtools, users can not only easily create and output profiles (RGB and CMYK), devicelink profiles, linearization charts, and control strips, but also calibrate and profile the monitor.

Check out this video to find out more about the MYIRO color management system.

Need help setting up color management in your workflow? Get in touch with our color specialists for a free consultation.