Importance of Imaging Colorimeters in OLED and MicroLED Display Inspection

OLED and MicroLED displays have become the forefront of display technology, transforming visual experiences on smartphones, TVs, and AR/VR headsets. The brilliance of these displays lies in the fact that each pixel acts as its own emitter, eliminating the need for a backlight. The result is stunningly vibrant colors, exceptional contrast ratios, and improved energy efficiency. Ensuring top-notch quality and performance of OLED and MicroLED displays necessitates thorough inspection and rigorous testing.

OLED and MicroLED Display Inspection Challenges

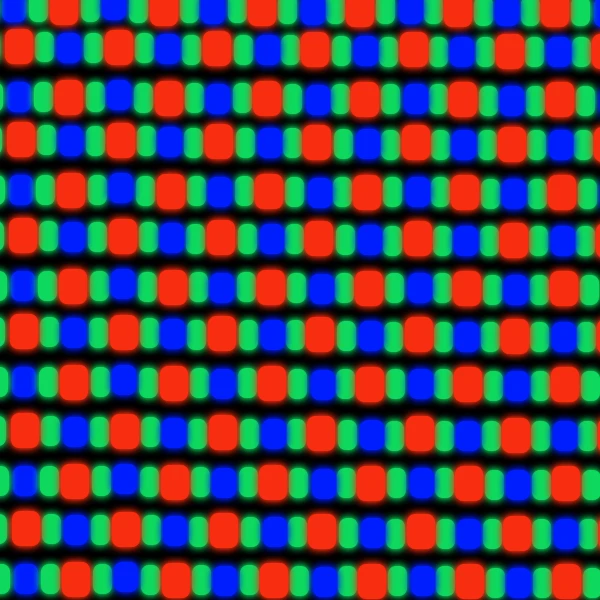

Inspecting OLED and MicroLED displays poses numerous challenges due to their distinctive characteristics and the complexities of these technologies. One of the most prominent challenges with these displays is ensuring uniformity across the entire display. In OLED and microLED displays, each pixel acts as an independent light source, which can lead to uneven brightness and color output among pixels and subpixels. Furthermore, the minute size of MicroLEDs adds complexity to the inspection process, as detecting defects or variations at this scale becomes even more challenging.

Imaging-based display test systems have proven effective in inspecting traditional LCD and LED displays. Typically, such a system comprises an imaging colorimeter and specialized test and analysis software. These display test systems can also be adapted to assess the visual quality and performance of OLED and MicroLED displays. One of the main advantages of imaging-based display test systems is their ability to accurately measure various visual aspects of a display, such as luminance, color, contrast, uniformity, mura, etc., allowing for precise evaluation and verification of the display’s performance against industry standards and specifications. Moreover, depending on their capability, they can be used for both R&D purposes as well as mass production testing and inspection.

Radiant Imaging Colorimetry-Based Display Test Systems for OLED and MicroLED

Radiant Vision System, a member of the Konica Minolta Group, offers an extensive range of display metrology solutions tailored for both research and development purposes and high-speed production inspection applications.

One notable inclusion in the portfolio is an imaging colorimetry-based display test system consisting of the ProMetric® I series Imaging Colorimeter and the powerful TrueTest™ Software. This advanced imaging-based display test system possesses the capability to measure a wide array of visual aspects in a display, including luminance, chromaticity, contrast, uniformity calibration (demura), subpixel-level measurement, line mura, defects, viewing angle, etc.

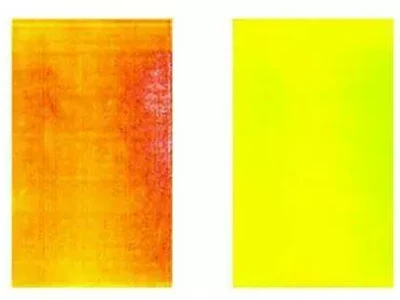

By leveraging Radiant’s patented methodologies, like the fractional pixel method or spaced pixel method, the imaging colorimetry-based display test system offered improved subpixel-level measurement and uniformity calibration (demura). It efficiently measures the luminance of every individual subpixel in a display, enabling more accurate calculation of correction factors for normalizing luminance discrepancies between the sub-pixels in the OLED or MicroLED display. Check out this whitepaper to learn more about the fractional pixel method and spaced pixel method.

Illustrative measurement images of a blue test screen on an OLED display, before and after demura correction, in a false-color scale using the TrueTest™ Software. Image courtesy of Radiant Vision Systems, LLC.

Do you need help with testing and inspecting your display? Or are you looking for assistance in finding the right display metrology instruments or solutions tailored to your specific needs? Contact our specialists for a free consultation now and let us guide you towards the perfect solution for your requirements.