Inspecting Heat Sealed Packaging With Hyperspectral Imaging To Enhance Food Safety and Quality

Quality assurance plays a crucial role in food production, encompassing a series of inspections and tests. One vital aspect of quality assurance is the thorough examination of food packaging. Besides ensuring the quality of the food itself, it is equally important to guarantee that the packaging meets the highest standards, as it not only safeguards the food but also helps maintain its freshness and extend its shelf life. Among the various packaging methods available, heat sealing is widely used for packaging a wide range of food products, including snacks, frozen foods, and perishable goods.

Heat sealing is a technique that involves the application of heat and pressure to fuse two layers of packaging material, creating a strong and airtight seal. Maintaining the quality of heat-sealed joints is crucial for food product freshness and safety. However, common issues like incomplete sealing, overheating, seal contamination, or misalignment, among others, can occur.

Traditional inspection methods, such as visual inspection, etc., have limitations and may not effectively identify subtle defects. Moreover, these methods can be time-consuming and prone to errors, rendering them inadequate for the demands of modern food production. Over the past few years, there has been a remarkable transformation in the inspection of heat-sealed joints, thanks to technological advancements. One such innovation is the use of hyperspectral imaging, a fast and reliable technology that provides accurate, efficient, and comprehensive inspection of sealed joints.

Understanding Hyperspectral Imaging

Hyperspectral imaging is an advanced technology that merges conventional imaging with spectroscopy, enabling the capture of both spatial and spectral information from objects or scenes. In contrast to traditional imaging, which captures images using the red, green, and blue color channels, hyperspectral imaging goes beyond limitations. It captures hundreds or even thousands of narrow and contiguous spectral bands, providing detailed material characterization based on unique spectral signatures. In simpler terms, it can “see” beyond what the human eye can detect, making it a valuable tool for inspecting heat-sealed joints.

A typical hyperspectral imaging system comprises a controlled light source and a hyperspectral sensor or camera. These sensors or cameras utilize various technologies, such as push-broom, etc., to capture data across multiple narrow and contiguous spectral bands. The collected data is then organized into athree-dimensional data cube and processed using specialized software and algorithms. Through analysis techniques, valuable information is extracted from the spectral signatures of each pixel, enabling tasks like material identification, classification, anomaly detection, and more.

Specim Hyperspectral Imaging Cameras for Heat Sealed Food Packaging Inspection

Specim, a leading hyperspectral imaging solutions provider, has a diverse selection of push-broom (line scan) hyperspectral cameras that have found applications in various fields like agriculture, food, pharmaceutical, medical science, art conservation, etc. Among these, the hyperspectral camera Specim FX17 demonstrated remarkable versatility across various industrial quality control and inspection, with heat-sealed joint inspection being one of the notable applications.

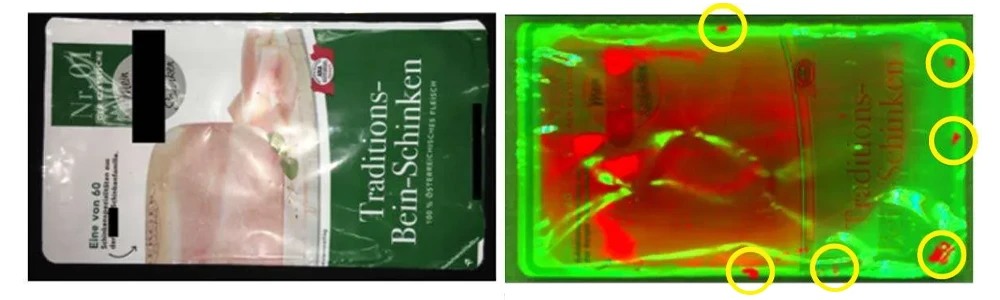

The hyperspectral camera Specim FX17 offers a hygienic and non-contact solution for inspecting heat-sealed food packaging. A notable advantage of the hyperspectral camera FX17 is its high resolution and frame-rate capabilities, enabling reliable detection of contaminants and defects, even on fast-moving production lines.

Inspecting heat-sealed food packaging with hyperspectral imaging camera Specim FX17.

Image courtesy of SPECIM, SPECTRAL IMAGING LTD

The hyperspectral camera Specim FX17 is designed for flexible and easy installation, whether new or existing production line. Check out this video to learn more about its capabilities.

Looking to leverage hyperspectral imaging for your applications? Contact us now for a complimentary consultation and explore the possibilities together