Poultry Carcass Inspection With Hyperspectral Imaging

Food safety and quality are of utmost importance in the agricultural and food processing industries in the modern era. With poultry being a widely consumed protein source worldwide, it is essential to implement rigorous inspection processes to protect consumers from potential health hazards. Conventional methods of poultry carcass inspection typically involve visual assessment or laboratory testing. While these methods of poultry carcass inspection have been somewhat effective, they have limitations. For example, visual inspection lacks the ability to detect subtle defects or contaminants, while sample testing through manual laboratory procedures is destructive and time-consuming. Therefore, more advanced and comprehensive approaches are required to ensure consumer safety and enhance product quality, and the forefront is hyperspectral imaging (HSI).

Hyperspectral Imaging Technology

Hyperspectral imaging is one of the latest technologies rapidly gaining popularity in the food and agricultural industries. Hyperspectral imaging combines the capability of imaging and spectroscopy, capturing both spectral and spatial information simultaneously, allowing non-destructive detection of external features and chemical or biological properties in foods and agricultural products.

The hyperspectral imaging process in poultry carcass Inspection involves several crucial steps. First, a hyperspectral camera is utilized to capture detailed spectral data for each pixel, forming the hyperspectral data or image. The collected hyperspectral data then undergoes pre-processing to correct any distortions, noise, etc., that might affect the accuracy of the analysis. The processed data is then analyzed, extracting relevant features or properties that indicate the quality and safety of the poultry carcass, such as contaminants, bruises, etc. Subsequently, data analysis techniques, including machine learning algorithms, are employed on the hyperspectral data. These algorithms are trained on a dataset using normal and defective poultry carcasses, enabling them to differentiate between different types of defects and contaminants in the poultry carcasses. This classification system empowers real-time decisions about the quality and safety of each poultry carcass based on its unique hyperspectral signature.

Recent research studies have demonstrated the remarkable potential of hyperspectral imaging in poultry carcass inspection. For instance, scientists at the Arkansas Agricultural Experiment Station were able to detect a chicken breast defect known as “woody breast” using hyperspectral imaging. A study by Chao et al. (2008) demonstrated the effectiveness of hyperspectral imaging in inspecting freshly slaughtered chicken carcasses on high-speed processing lines. The researchers reported an impressive accuracy rate of over 99% and 96% in identifying wholesome and unwholesome chickens, respectively.

Specim Hyperspectral Cameras for Poultry Carcass Inspection

Specim offers a range of line scan (pushbroom) hyperspectral cameras, from portable to advanced industrial models, widely used in various food quality and safety inspection applications, including fruits/vegetables, nuts, etc.

Among their hyperspectral camera lineup, the Specim FX series stands out with its VNIR hyperspectral camera FX10 and NIR hyperspectral camera FX17. These cameras are ideal when it comes to inspecting poultry carcasses, particularly on high-speed processing lines. The hyperspectral camera FX10 and hyperspectral camera FX17 can be easily integrated into existing machine vision systems or optical sorting systems, ensuring seamless operation. With a high frame rate, both the FX10 and FX17 hyperspectral cameras are capable of meeting the demands of high-speed processing or sorting.

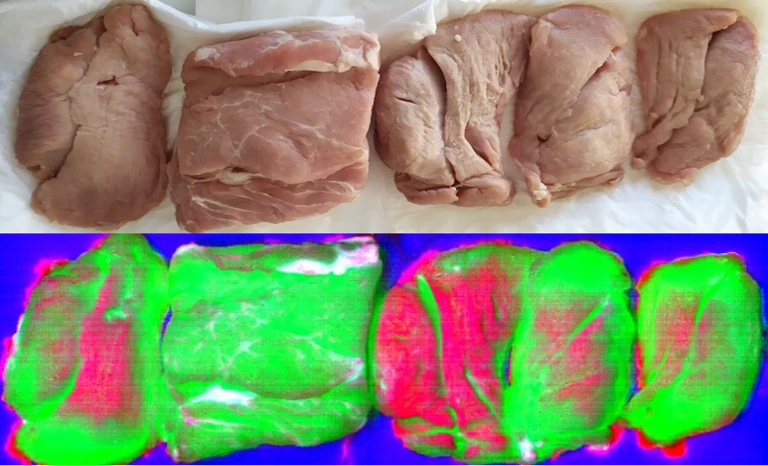

Detecting and classifying poultry meats with Specim FX17 hyperspectral camera.

Image courtesy of SPECIM, SPECTRAL IMAGING LTD

Check out the videos showcasing the FX10 and FX17 hyperspectral cameras to learn more about their capabilities.

For comprehensive information on Specim’s hyperspectral cameras and solutions, or if you need assistance finding the hyperspectral solutions suitable for your food applications, reach out to us for a complimentary consultation now.