Color Measurement in Recycled Plastic Compounding Process

The increasing concern about plastic pollution has highlighted the urgent need for effective waste management strategies. A vital component of this strategy is the recycling of plastic, which involves a meticulous process of collection, sorting, cleaning, and ultimately transforming discarded plastics into new, usable products. This is achieved through plastic compounding, wherein recycled plastics are blended with various additives, fillers, and reinforcing materials to yield specific characteristics such as improved strength, flexibility, flame resistance, or color.

As compounding involves the addition of various additives and colorants, color measurement plays a crucial role in the recycled plastic compounding process. This step ensures that the recycled plastic compounds meet the specific color requirements of the clients, maintain consistency across batches, and fulfill the aesthetic and functional requirements of various applications.

Objective Color Measurement with Spectrophotometer

Spectrophotometers play a critical role in a wide range of industries, including chemicals, plastics, etc. These color measurement tools provide objective color data for quality control processes, ensuring color standards or customer expectations are maintained and met. Additionally, they support research and development efforts by offering precise data for formulating new products and materials. A spectrophotometer operates on the principle of measuring the reflectance or transmittance of light across different wavelengths. This information is then converted into color spaces, such as the CIE L*a*b* color space. The CIE L*a*b* color space is a three-dimensional representation of colors that offers a standardized framework for communicating color information. It consists of three coordinates: L*, representing the lightness of the color; a*, describing the position on the green-red axis; and b*, indicating the position on the blue-yellow axis. These coordinates provide numerical values for each color parameter, facilitating the establishment of color tolerance to evaluate acceptable color differences.

Spectrophotometers operate in various measurement modes, such as reflectance or transmittance, and the selection of the appropriate mode is crucial for obtaining accurate and meaningful data based on the nature of the sample. In reflectance mode, the spectrophotometer measures the amount of light reflected off the sample’s surface, making it suitable for opaque or solid plastic samples. On the other hand, transmittance mode allows the spectrophotometer to measure the amount of light that passes through a sample, providing insights into its color characteristics. This mode is typically used for transparent or translucent plastic or liquid samples.

Konica Minolta Color Measurement Solutions for Recycled Plastic Compounds

Konica Minolta offers a range of color measurement solutions specifically designed for the plastic industry, including recycled plastic compounding. Among these, the Spectrophotometer CM-36dG offers the flexibility of both reflectance and transmittance color measurements, making them suitable for a wide range of recycled plastic compounding applications.

Spectrophotometer CM-36dG reflectance (left) and transmittance (right) color measurement of plastics.

With good repeatability and inter-instrument agreement of ∆E*ab < 0.02 and ΔE*ab < 0.12, respectively, the spectrophotometer CM-36dG provides users and manufacturers with the confidence and control needed to produce recycled plastic compounds with minimal color variability and ensures consistent color quality across production runs, even at different locations.

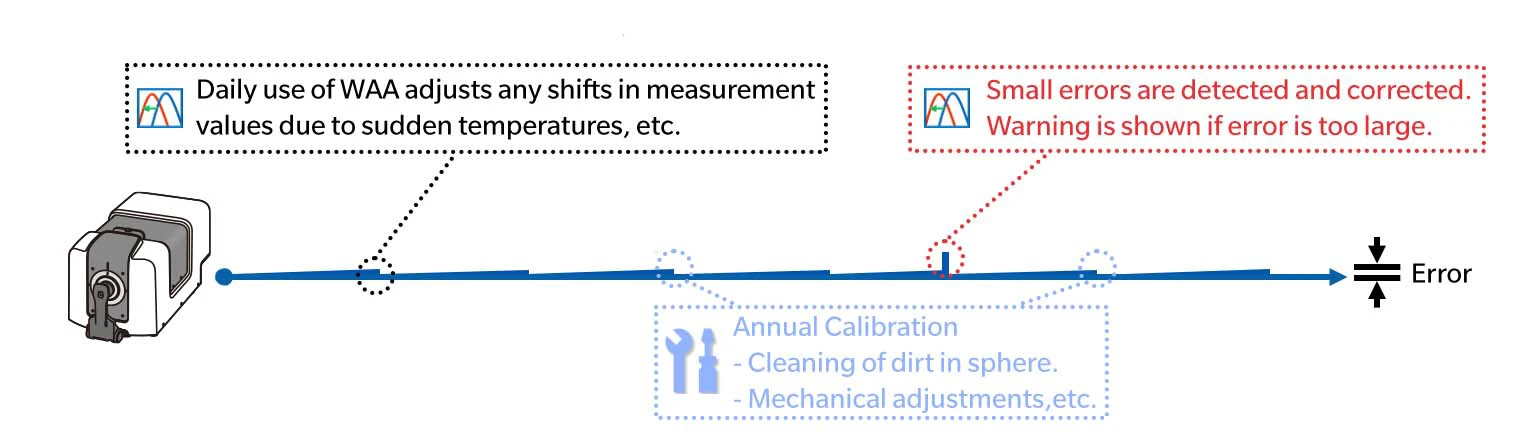

The Spectrophotometer CM-36dG offers various measuring area options and is supported by a wide range of accessories for a hassle-free and efficient measurement process. Alongside precise and consistent color measurements, this versatile color measurement instrument also features an integrated 60° gloss sensor, enabling simultaneous measurement of both color and gloss. Moreover, the Spectrophotometer CM-36dG offers an optional Wavelength Analysis & Adjustment (WAA) function that helps correct any wavelength shift in the instrument during calibration, ensuring long-term measurement accuracy and reliability.

Wavelength Analysis & Adjustment (WAA) function.

When used in conjunction with the color management software SpectraMagic NX or SpectraMagic NX2, the Spectrophotometer CM-36dG’s functionality is further enhanced. These software options offer trend analysis and personalized reporting, including the creation of custom color formulas to meet specific requirements. Watch this video to learn more about the full capabilities of Spectrophotometer CM-36dG.

Looking for assistance in finding the right color measurement instruments and solutions for your plastic applications? Contact us now for a complimentary consultation.