Pill and Tablet Film Coating Measurement With Spectrophotometer

When it comes to medication, one often overlooked factor is the color of pills or tablets. While some may view color as purely aesthetic, it actually serves a significant purpose in the pharmaceutical industry. Color plays a vital role in medication adherence, particularly for patients who need to take multiple medications at different times of the day. Distinct colors help them differentiate between medications, minimizing the risk of mix-ups. Additionally, studies have shown that consumers associate specific colors with certain types of medication. For example, white or blue tablets are often perceived as bitter, while pink tablets are thought to have a sweeter taste than red ones. Interestingly, a color change can even impact a patient’s adherence to prescribed pills, potentially leading them to stop taking them altogether.

One key factor that contributes to the color of a pill or tablet is its film coating. Pill and tablet film coating is a vital pharmaceutical process for solid dosage forms that have been in existence for a long time. This thin layer of coating is applied to pills and tablets to provide a protective layer to the drug, ensuring that it is not affected by external factors such as light, moisture, or air. It also serves to mask taste or is used for aesthetic purposes, making the pill and tablet more visually appealing.

Pill and Tablet Film Coating Color Measurement

With advancements in technology, spectrophotometers have emerged as the preferred tool for measuring color in the pharmaceutical industry. These devices emit light at a sample, and the amount of light that is reflected or transmitted at various wavelengths is measured. The resulting data is then converted into quantifiable color data, which is commonly represented using established color spaces such as CIE L*a*b*. This method of color measurement ensures precise and accurate results, which are of paramount importance in pharmaceutical applications where the slightest variation can result in significant consequences.

Suppliers of excipients, like film coating, are often required to measure the color of the film coating to compare different colors to match their customers’ color codes. During the development of coating film for pills, it is imperative to create prototypes to ensure proper color matching that aligns with customer specifications. Initially, the film is measured in its liquid state after the completion of color mixing. Subsequently, film sheets are produced and measured, which eventually leads to the measurement of the color of the actual film-coated pill. Similarly, film coating for tablets also undergoes the same process and color measurement methods employed for coating the film of the pill. The distinction lies in the type of coating required, whether it be transparent or colored.

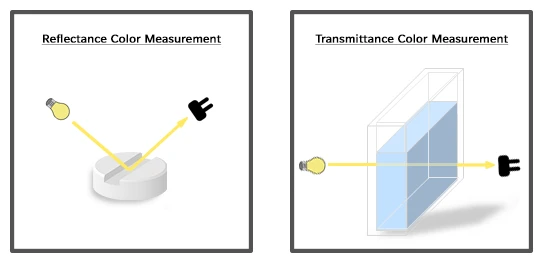

When it comes to assessing the color of pill or tablet film coating, there are two primary methods: reflectance color measurement and transmittance color measurement. Reflectance color measurement is the most commonly utilized method, although transmittance measurement can also be employed based on specific requirements (e.g., liquid, transparent film, etc.). One crucial consideration when measuring the color of the film-coated pill or tablet is its size and shape. This is because the size of the aperture used in the spectrophotometer can significantly impact measurement accuracy. Hence, careful consideration is necessary to ensure the aperture size aligns with the pill or tablet being assessed.

Illustrative example of reflectance and transmittance color measurement

Konica Minolta Color Measurement Solutions for Pill and Tablet Film Coating

Konica Minolta Sensing, a trusted name in the field of color measurement solutions, offers an extensive range of spectrophotometers and colorimeters that provide precise and reliable color evaluations for various industries. Among these, the Spectrophotometer CM-5 is the go-to solution for accurate and reliable color measurement in the pharmaceutical industry. Its advanced technology, versatility, and user-friendly operation make it an essential tool for ensuring product quality and consistency in this highly regulated industry.

The Spectrophotometer CM-5 offers a broad range of measurement capabilities, including the widely used CIE L*a*b* and other industry-specific indices, such as European Pharmacopoeia (EP), US Pharmacopeia (USP), APHA/Hazen, and Gardner. The instrument is capable of performing both reflectance and transmittance color measurements, allowing for comprehensive evaluation of various sample types, ranging from film-coated pills or tablets to liquids and film sheets. The Spectrophotometer CM-5 is supported by apertures of different sizes, ranging from Φ3 mm to Φ30 mm, and is accompanied by various accessories such as petri dishes and tube cells that facilitate easy and consistent presentation and measurement of samples.

Spectrophotometer CM-5 measuring color of tablet (left), opaque liquid (center), and translucent liquid (right).

Furthermore, the capabilities of the spectrophotometer CM-5 can be further enhanced with the color management software SpectraMagic NX or SpectraMagic NX2. The software allows for customizable reporting, trend tracking, and the ability to create custom color formulas tailored to specific requirements. Watch this video to learn more about the diverse and flexible functionality of Spectrophotometer CM-5.

Require assistance in accurately measuring the color of your pharmaceutical products? Connect with us to schedule a complimentary consultation with our team of color application experts. We’re here to provide the best solutions and assist you in overcoming any challenges in color measurement.