Harnessing Hyperspectral Imaging in the Food Industry

The food industry is undergoing a transformative shift, driven by technological advancements that aim to enhance food quality and safety. One such transformative technology is hyperspectral imaging (HSI), which has already demonstrated its potential in various aspects of food production and processing. This non-contact, non-destructive imaging technology captures and analyzes data across a broad spectrum of light, enabling detailed insights into the composition and characteristics of food products, making it invaluable for food quality control and inspection.

Hyperspectral imaging works by capturing images at many narrow wavelength bands across the electromagnetic spectrum, from the visible light spectrum (about 400-700 nm) to the near-infrared (NIR) region (up to 2500 nm). Each pixel in a hyperspectral image contains a full spectrum of data, enabling the identification and analysis of materials based on their unique spectral signatures. Unlike conventional imaging methods, which capture images in the red, green, and blue (RGB) bands, hyperspectral imaging allows for detecting subtle differences in the chemical composition and physical properties of materials. In the food industry, these capabilities translate into the ability to identify contaminants, monitor quality, and optimize production processes to meet the growing demands of consumers and regulators.

Ensuring Food Safety and Quality Control

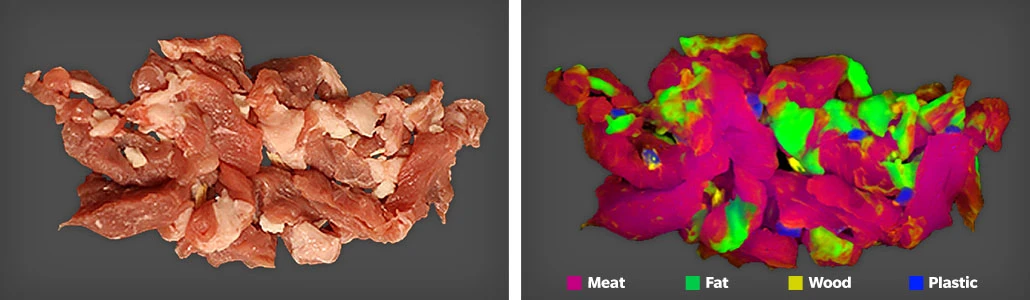

One of the primary applications of hyperspectral imaging in food safety is the detection of contaminants. The ability to identify foreign objects such as plastic, glass, metal, and even biological contaminants makes hyperspectral imaging invaluable. For instance, in the meat processing sector, hyperspectral imaging can detect bone fragments or cartilage that might be missed by standard inspection techniques.

Hyperspectral imaging detecting foreign objects and characterizing fat content in meat.

Image courtesy of SPECIM, SPECTRAL IMAGING LTD.

In addition to contaminant detection, hyperspectral imaging is essential for quality control, as it can assess the freshness and quality of food products by analyzing their chemical composition, including fat, protein, water content, etc. A practical application of this technology is its capacity to distinguish between normal breast meat and denser woody breast meat in chicken, thereby minimizing waste by redirecting the latter for use in processed food products.

Enhancing Sorting and Grading Processes

Sorting and grading are fundamental processes in most food production. Traditional sorting methods often rely on visual inspection, which can be time-consuming and prone to errors. Hyperspectral imaging, however, automates and enhances these processes by providing detailed information about both the internal and external characteristics of food items.

In the processing of fruits and vegetables, hyperspectral imaging can assess the ripeness, color, and presence of defects in produce. For instance, it can detect bruising or internal damage in apples that might not be visible externally, allowing for more accurate grading and sorting. Similarly, hyperspectral imaging is valuable in the high-speed sorting and classification of nuts. Internally damaged almonds, for example, can be difficult to differentiate from healthy ones based solely on their external appearance. However, by analyzing their spectral signatures, hyperspectral imaging effectively distinguishes between internally damaged almonds and normal ones.

Distinguishing walnuts from their shells using Hyperspectral Imaging.

Image courtesy of SPECIM, SPECTRAL IMAGING LTD.

Inspecting Heat-Sealed Packaging

Hyperspectral imaging offers a significant advantage in packaging inspection, offering insights that traditional methods may overlook. Proper packaging not only protects food from contamination but also preserves freshness. Heat sealing, a widely used packaging technique, employs heat and pressure to create airtight seals, ensuring product safety. However, defects in the sealing process, such as incomplete seals or trapped contaminants, can compromise the integrity of the packaging and the safety of the food inside.

By analyzing the spectral signature of the sealed area, hyperspectral imaging can identify variations that indicate the presence of contaminants, such as food particles or foreign substances, which can interfere with the sealing process. Furthermore, hyperspectral imaging can identify inconsistencies in seals, such as overheating, misalignment, etc., which might lead to leaks or compromise product integrity.

Specim Hyperspectral Imaging Solutions for the Food Industry

As the food industry continues to evolve, the role of hyperspectral imaging is expected to grow. Specim, part of Konica Minolta Group, is a pioneer and leader in hyperspectral imaging technology, offering an extensive range of pushbroom (line scan) hyperspectral cameras covering various spectral wavelength regions from VNIR (visible and near-infrared) to LWIR (long-wave infrared). The industrial-grade Specim FX series hyperspectral camera is designed for easy integration into existing food production lines, offering high spectral resolution and frame rate to meet the demands of fast-paced food inspection. Additionally, the Specim portfolio includes the Specim IQ, a portable and handheld hyperspectral imaging camera that opens up new possibilities for on-site inspections and quality control in the field. Check out the Specim FX and Specim IQ videos to learn more about the capabilities of these hyperspectral imaging cameras.

WATCH VIDEO

For more information about Specim’s hyperspectral imaging cameras or assistance in identifying the right hyperspectral imaging solutions for your food applications, contact us for a complimentary consultation. Our team of experts is here to help you explore options, ensuring you find the ideal hyperspectral imaging solution that meets your needs.