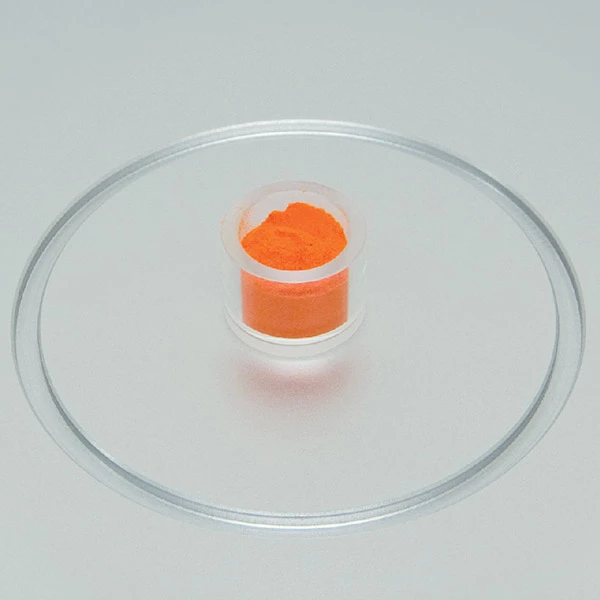

Measure Color of Powdered Raw Materials

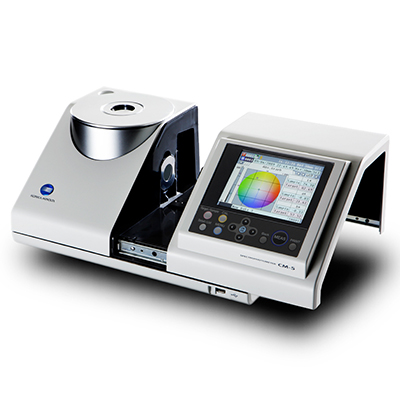

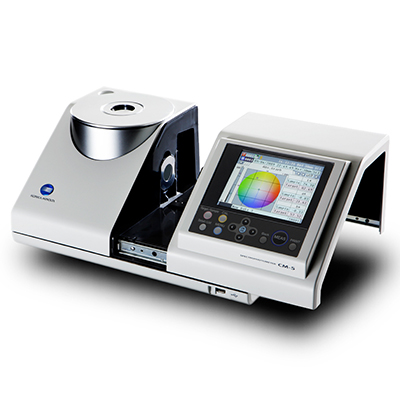

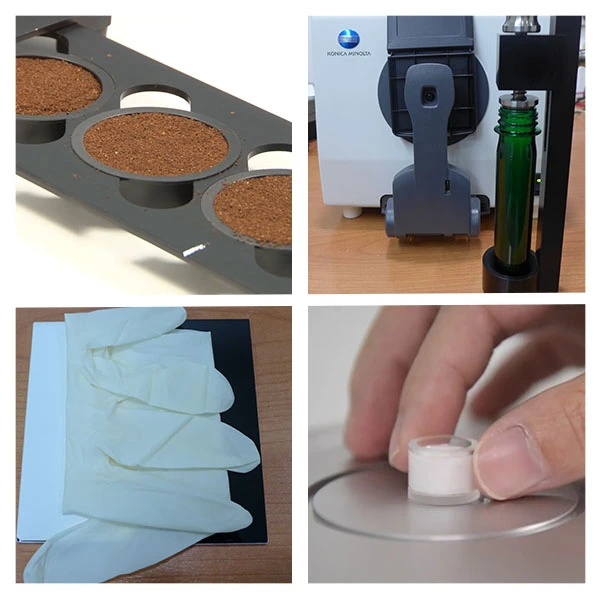

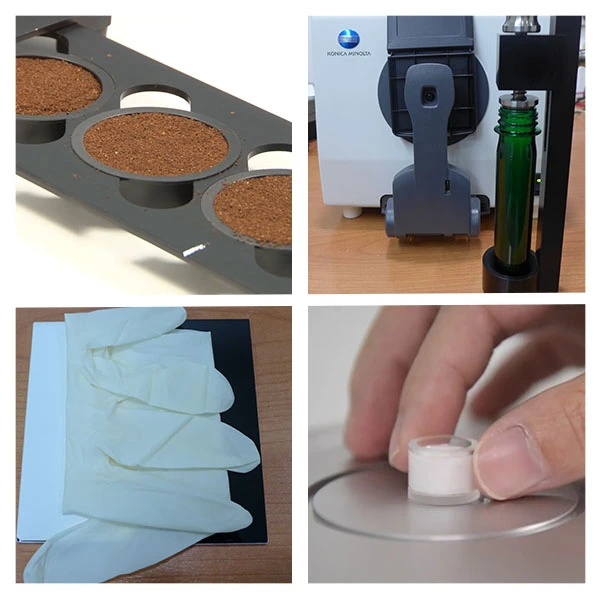

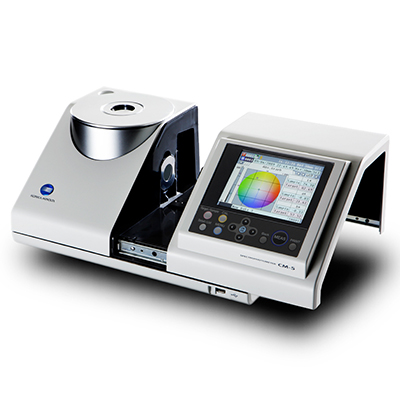

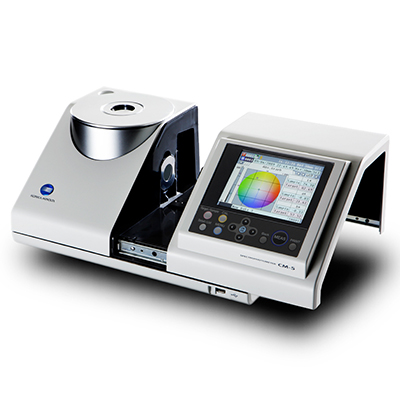

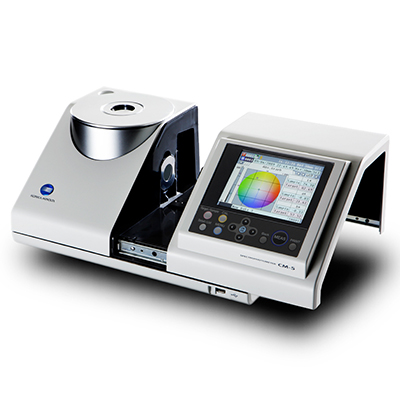

Consistent color control of powdered raw materials—such as pigments, fillers, cement powders, and mineral powders—is essential for minimizing variation during formulation and ensuring stable downstream quality. Because powders can vary in particle size and surface texture, precise and repeatable measurement is critical. Konica Minolta offers a range of accurate and traceable color measurement solutions tailored for powder evaluation. Color measurement instruments such as the Spectrophotometer CM-5, Spectrophotometer CM-36dGV, and Spectrophotometer CM-3700A Plus provide reliable measurement of powder color, including whiteness. These color measurement instruments are supported by various dedicated accessories, helping standardize sample presentation for consistent, controlled, and repeatable results across batches.

Recommended Products:

Spectrophotometer CM-3700A Plus

Spectrophotometer CM-36dG

Spectrophotometer CM-5

Related Links:

Measure Color of Liquid Raw Materials

Color accuracy in liquid raw materials—such as resins, binders, dispersions, slurries, and admixtures—is essential for maintaining formulation stability and ensuring consistent performance during downstream processing. Because liquid samples can vary in appearance due to changes in opacity, temperature, or suspended particles, precise and repeatable instrumental measurement becomes vital. Konica Minolta’s Spectrophotometer CM-5, Spectrophotometer CM-36dG, and Spectrophotometer CM-3700A Plus deliver dependable color and transmittance measurement across a broad range of liquid applications. When paired with specialized cuvettes and accessories that ensure controlled sample conditions, these instruments enable manufacturers to achieve uniform and repeatable results, maintaining tighter control over overall production quality.

Recommended Products:

Spectrophotometer CM-5

Spectrophotometer CM-36dG

Spectrophotometer CM-3700A Plus

Related Links:

Color Quality Control and Verification

Achieve consistent, reliable color across ceramic tiles, panels, composites, and coated surfaces with objective color measurement solutions. Instrument-based color control replaces subjective visual checks, delivering accurate results regardless of surface texture, gloss, or lighting conditions. From incoming materials to final inspection, color measurement solutions help detect deviations early, maintain batch-to-batch consistency, and reduce rework and waste. Konica Minolta offers a wide selection of color measurement solutions, like the Spectrophotometer CM-17d, the Spectrophotometer CM-26dG, the Spectrophotometer CM-36dG, and the Spectrophotometer CM-5, that provide accurate and repeatable color measurement for opaque materials in both laboratory and production environments. These color measurement instruments support efficient color verification and batch comparison, enabling manufacturers to maintain consistent appearance and minimize quality deviations.

Recommended Products:

Spectrophotometer CM-17d

Spectrophotometer CM-26dG

Spectrophotometer CM-36dG

Related Links:

Gloss and Surface Finish Measurement

For some opaque building materials—such as ceramic tiles, enamel-coated surfaces, resin-based materials, and stainless steel—surface appearance plays a critical role in perceived quality. These materials often incorporate gloss or semi-gloss finishes, where even tiny variations in gloss level can result in noticeable visual inconsistencies. Konica Minolta, in partnership with Rhopoint, offers a range of dedicated gloss and surface appearance measurement solutions to support accurate evaluation across a wide range of finish levels. Instruments such as the Rhopoint IQ Flex 20-S and Rhopoint IQ-S enable advanced analysis of gloss, DOI, reflection haze, and surface characteristics, helping manufacturers identify subtle finish variations and surface defects. For routine gloss measurement and process control, the Konica Minolta Multi Gloss MG-268A Gloss Meter and Uni Gloss UG-60A / 60CT / 60S Gloss Meters deliver precise and repeatable results in both laboratory and production environments.

Recommended Products:

Multi Gloss MG-268A Gloss Meter

Uni Gloss UG-60A/60CT/60S Gloss Meter

Rhopoint IQ-S

Related Links:

Color Quality Control for Textured and Irregular Surfaces

Textured building materials—such as stone, wood, metal, or ceramic products with rough, patterned, or uneven surfaces—present measurement challenges due to surface irregularities and diffuse light reflection. To capture representative color data across these irregular surfaces, color measurement instruments with larger measurement apertures are essential, as they average color over a wider area and reduce the influence of local surface variations. Konica Minolta offers portable and benchtop color measurement instruments, such as the Chroma Meter CR-410, the Spectrophotometer CM-5, and the Spectrophotometer CM-36dG, equipped with large-aperture measurement suitable for textured and non-uniform materials. These color measurement instruments deliver stable and repeatable color results, enabling manufacturers to verify color consistency and minimize variability caused by surface structure.

Recommended Products:

Related Links:

Color Quality Control and Verification

Transparent and semi-transparent building materials—such as colored glass, tinted acrylic, and pigmented polycarbonate—require precise control of color whereby any variations in thickness, formulation, or processing can produce noticeable differences in appearance and light transmission. It is particularly critical for colored glazing, panels, and architectural components, where visual uniformity directly influences both design intent and functional performance. Transmission color measurement enables objective verification of optical properties throughout production. Konica Minolta’s Spectrophotometer CM-5, Spectrophotometer CM-36dG, and Spectrophotometer CM-3700A Plus provide accurate transmittance color measurement for colored transparent and semi-transparent materials, supporting uniform tint control, batch-to-batch consistency, and compliance with design and quality specifications.

Recommended Products:

Spectrophotometer CM-5

Spectrophotometer CM-36dG

Spectrophotometer CM-3700A Plus

Related Links:

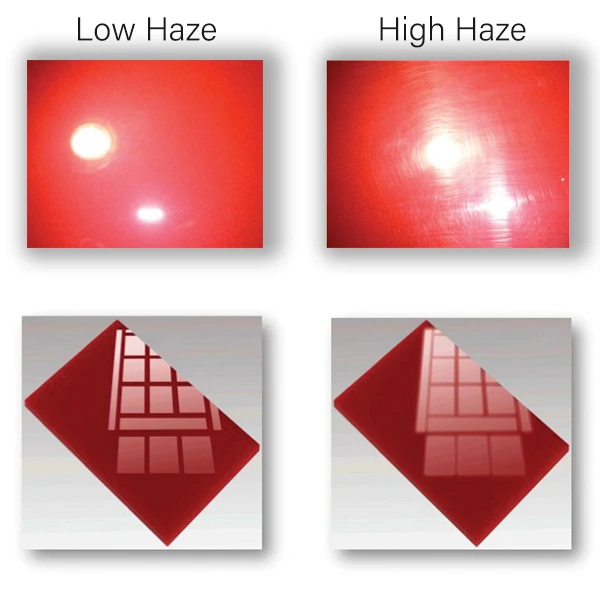

Clarity and Visibility Evaluation

Clarity is strongly influenced by transmission haze in transparent building materials. Transmission haze can cause a cloudy or blurred appearance, reducing visibility and negatively impacting both aesthetic quality and functional performance. Precise measurement of transmission haze is essential for ensuring consistent clarity and visual performance. Konica Minolta color measurement instruments, such as the Spectrophotometer CM-5, Spectrophotometer CM-36dG, and Spectrophotometer CM-3700A Plus, when combined with the optional SpectraMagic™ NX2 color data software, enable simple and fast correlated haze evaluation, helping manufacturers maintain consistent optical quality and improve batch-to-batch uniformity.

Recommended Products:

Spectrophotometer CM-3700A Plus

Spectrophotometer CM-36dG

Spectrophotometer CM-5

Related Links:

Color Specification, Control, and Verification

For sealants and adhesives—such as grouts, fillers, and related materials—accurate color specification and control are essential to ensure visual compatibility after application and curing. Color variation can arise from formulation differences, pigment dispersion, or curing conditions, making objective, instrument-based measurement critical. Benchtop spectrophotometers such as the Konica Minolta CM-3700A Plus serve as a reference-grade instrument for establishing color standards and tolerances. Furthermore, the Konica Minolta CM-36dG and CM-5 support formulation evaluation, laboratory quality control, and detailed color analysis under controlled conditions. Portable spectrophotometers such as the Konica Minolta CM-26dG and CM-17d enable fast and reliable color measurement and verification of production samples applied to drawdown cards, helping manufacturers maintain consistent color and ensure products remain within specification throughout the manufacturing process.

Recommended Products:

Spectrophotometer CM-3700A Plus

Spectrophotometer CM-36dG

Spectrophotometer CM-5

Related Links: