Measuring Metallic and Pearlescent Paints

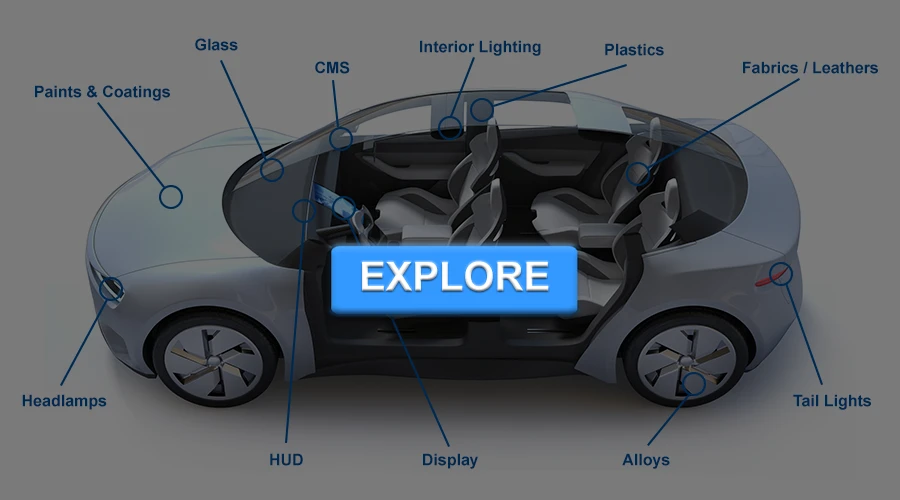

The automotive industry places great importance on achieving an aesthetically pleasing appearance for vehicles, and metallic and pearlescent paints are popular choices due to their unique visual effects that enhance the overall appeal of the vehicles. However, measuring and ensuring consistency can be challenging due to their complex nature. Metallic and pearlescent paints contain flakes that vary in size and orientation, resulting in angle-dependent color changes. This makes accurate color measurement difficult. The Konica Minolta Multi-Angle Spectrophotometer CM-M6 captures accurate color data from multiple angles, typically ranging from -15° to 110°, making it ideal for quantifying the color travel effect. Additionally, it is equipped with a patented double-path illumination system, ensuring reliable color measurement of metallic and pearlescent paints, even on curved surfaces.

Recommended Products:

Related Links:

Evaluate Paints/Coatings Finishes

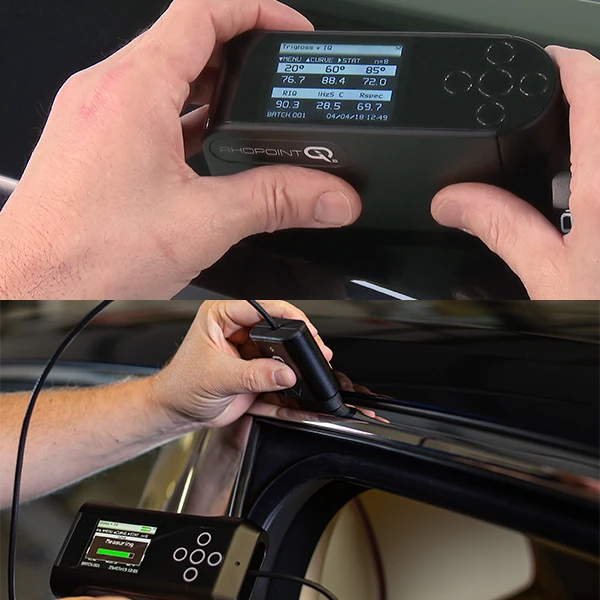

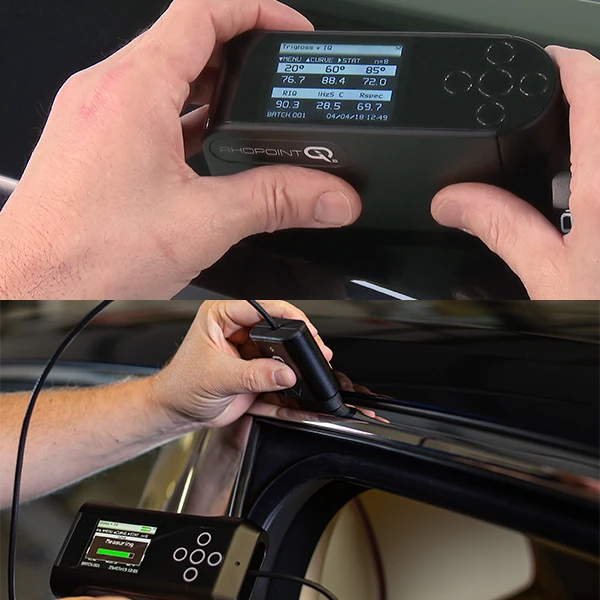

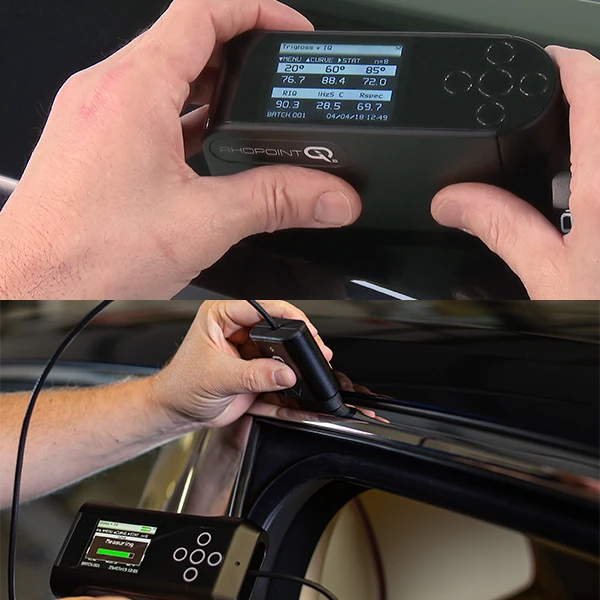

In addition to color, the finishing of an automotive exterior is also one of the most prominent and impactful factors in determining the overall appearance of a vehicle. The evaluation of automotive finishing involves several key attributes, including measuring gloss, haze, orange peel, etc. Traditionally, multiple instruments were required to measure these parameters. Gloss meters are used to measure the specular reflection of light on a surface, haze meters quantify reflection haze, and DOI (Distinctness of Image) meters are utilized to capture the undesirable orange peel effect in the coating.

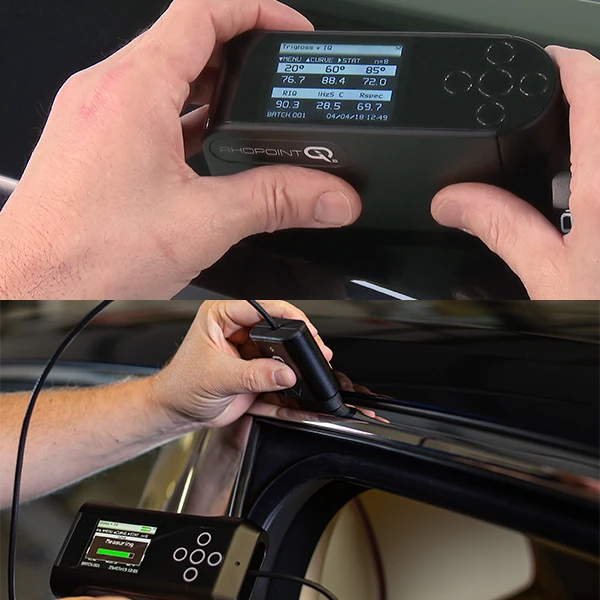

The Rhopoint iQ-S is a comprehensive instrument that combines various measurement parameters, like gloss, reflection haze, DOI, and RIQ (Reflected Image Quality), into a single device, allowing for efficient and accurate assessment of automotive finishing. The Rhopoint TAMS™ is another advanced instrument used for evaluating finishing quality, particularly for assessing complex textures and finishes. It offers new parameters like contrast, sharpness, waviness, dimension, etc., enabling the evaluation of orange peel and surface roughness that better correlate with human perception of surface appearance quality.

Recommended Products:

Related Links:

Coordinating Color Across Different Materials

Automotive interiors encompass a range of materials used in the cabin of modern cars. These include plastics, textiles, metal, and leather, among others. Coordinating colors across different materials within the automotive interior is crucial for design coherence, brand identity, and user satisfaction. Color variations can occur due to material and process differences, so manufacturers rely on color measuring instruments to set tolerance limits for color checks. Konica Minolta offers a wide selection of high-precision color measuring instruments like the Spectrophotometer CM-26dG, Spectrophotometer CM-25cG, Spectrophotometer CM-17d, etc. These tools provide an objective and quantitative approach to measuring colors, facilitating quality control, color matching and communication, supporting material selection, and more.

Recommended Products:

Spectrophotometer CM-26dG

Spectrophotometer CM-25cG

Spectrophotometer CM-17d

Related Links:

Evaluate Gloss and Surface Finish Quality of Materials

The visual appeal and perceived quality of automotive interiors are influenced by factors beyond just color. The gloss and surface finish of materials play a significant role in enhancing the overall aesthetics. From matte plastic to shiny chrome parts, the level of gloss varies. Konica Minolta and partner Rhopoint Instruments provide a wide range of measurement solutions to assess gloss and surface finish quality in automotive interior materials. The Rhopoint iQ-S offers simultaneous gloss measurement at 20°, 60°, and 85° angles, making it suitable for various materials, from matte to mirror finishes. The Rhopoint IQ Flex 20-S and Novo-Gloss Flex 60 enable gloss measurement on small footprint areas, including small and curved surfaces, at 20° and 60° angles, respectively.

Recommended Products:

Related Links:

Testing Embedded OLEDs and LCDs

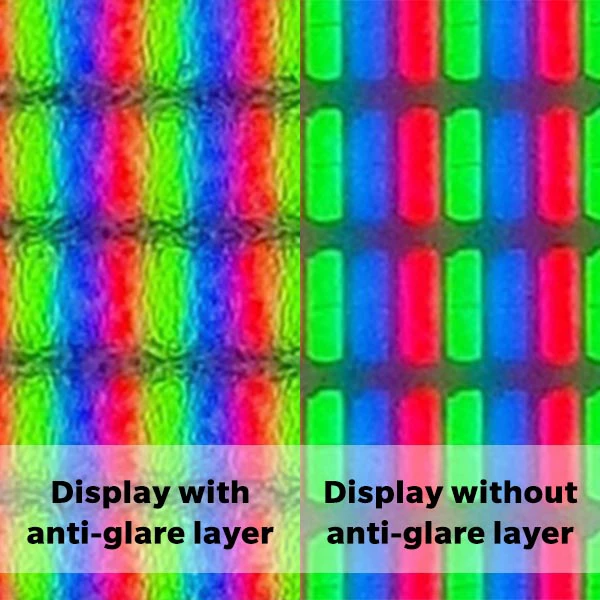

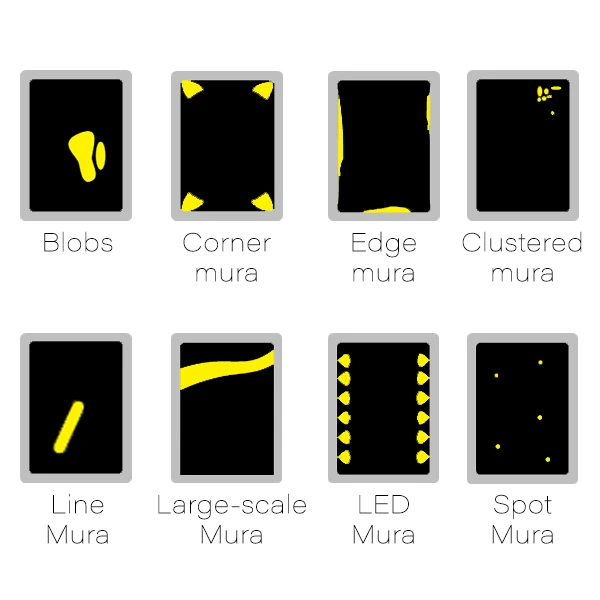

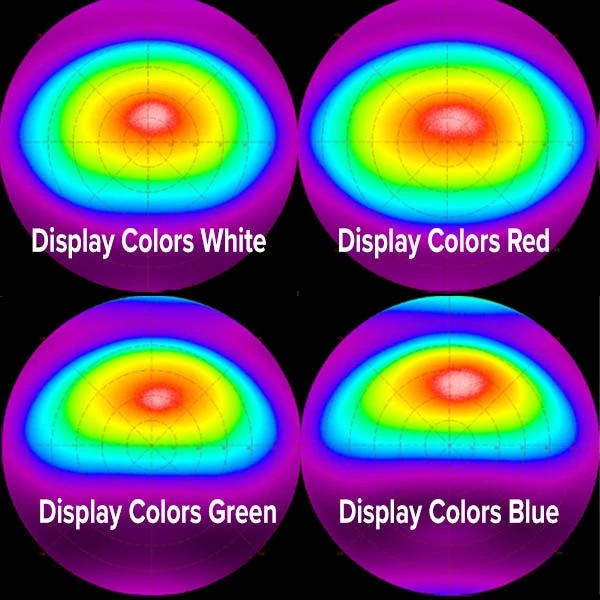

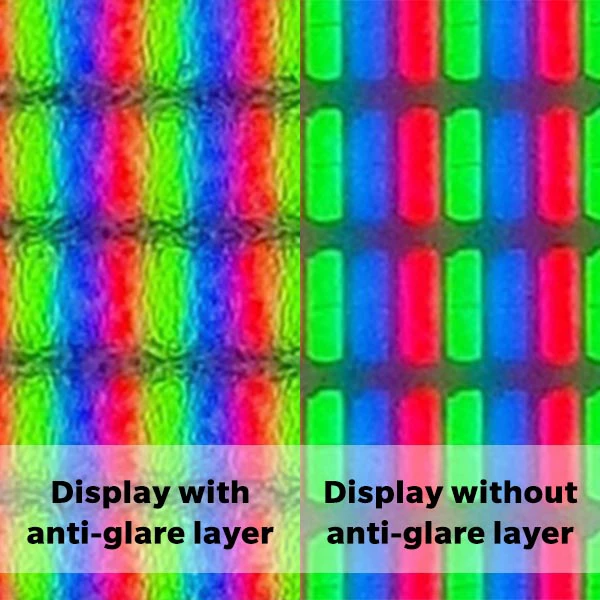

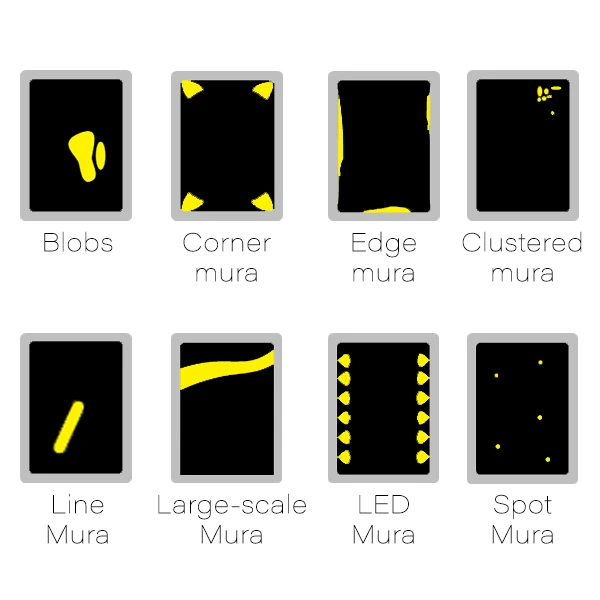

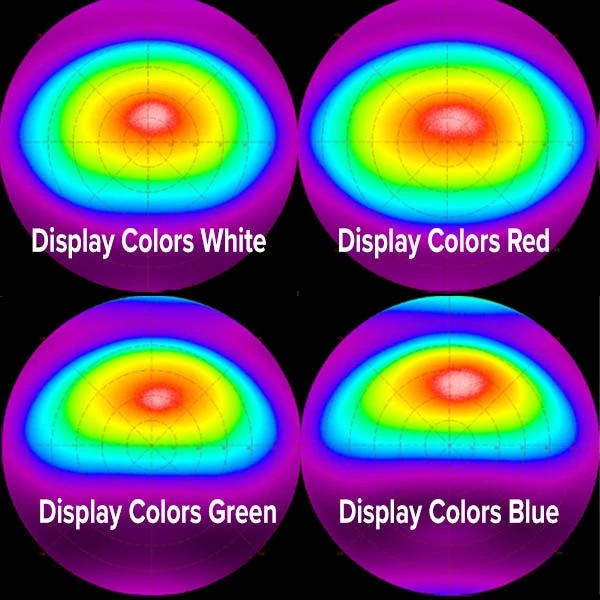

Display technology, such as OLEDs and LCDs, is rapidly becoming the standard for automotive instrumentation, information, navigation, and entertainment systems. Consumers, accustomed to high-quality visuals from their TVs, computers, and phones, have high expectations for color and clarity in these displays. In addition, these displays also provide critical information to drivers, including speed, navigation directions, and warnings. Ensuring the displays’ performance, visibility, and legibility requires rigorous testing and inspection. Konica Minolta, with group company Radiant Vision Systems, offers a wide selection of measurement solutions, from state-of-art Spectrophotometer CS-3000 series and Display Color Analyzer CA-410 series to ProMetric® Imaging Colorimeter or Photometer, that can evaluate and inspect display performance, including luminance, chromaticity, uniformity, line/pixel defects, mura, and many more.

Recommended Products:

Spectroradiometer CS-3000 Series

Display Color Analyzer CA-410 Series

ProMetric® I Series - Imaging Colorimeter

Related Links:

Evaluating Head-Up Displays (HUDs)

Head-up display (HUD) technology has become a key focus in the automotive industry, driven by the growing concern for passenger and vehicle safety. HUDs project important vehicle and navigation information within the driver’s field of view, ensuring minimal distraction. The imaging quality of the HUDs plays a vital role in clear and accurate information delivery and requires evaluating the luminance, chromaticity, contrast, focal distances, etc., of HUD images. Konica Minolta, with group company Radiant Vision Systems, offers an automated HUD measurement system comprising of ProMetric® Imaging Colorimeter or Photometer and TrueTest™ software with TT-HUD™ module that is capable of providing both accurate photometric and dimensional (spatial data) measurements at any working distance.

Recommended Products:

ProMetric® I Series - Imaging Colorimeter

ProMetric® Y Series - Imaging Photometer

Related Links:

Inspecting Backlit Symbols

Backlit components and signs in automotive instrument clusters, controls, and indicators play a crucial role in conveying important safety and operational information. It is vital to inspect the visibility of these components and ensure they are free from defects. Common issues include misshapen or misplaced elements, incorrect luminance and chromaticity, and non-uniform illumination of the light source. The ProMetric® Imaging Colorimeter or Photometer combined with vision Inspection Pack (VIP™) software, provide a single and comprehensive visual inspection solution that can evaluate the luminance and chromaticity of backlit components or signs while detecting any dimensional integrity issues.

Recommended Products:

ProMetric® I Series - Imaging Colorimeter

ProMetric® Y Series - Imaging Photometer

Related Links:

Whitepaper

Automotive Industry Lighting Control: Photometric & Colorimetric Measurement of Car Cockpit

Read Now →

Whitepaper

Automotive Industry Lighting Control: Photometric & Colorimetric Measurement of Car Cockpit

Read Now →

Headlights and Brake Lights Evaluation

Automotive exterior lighting, including headlights, sidelights, fog lights, indicators, brake lights, and taillights, plays a significant role in ensuring safety, visibility, and communication on the road. These lighting must undergo rigorous evaluation and inspection against various parameters to ensure optimal illumination and visibility and meet the safety regulations. Konica Minolta and its group company, Radiant Vision Systems, offer a comprehensive range of measurement solutions to ensure compliance with today’s stringent regulations and standards for automotive lighting. With the ProMetric® Imaging Colorimeter or Photometer, you can assess the illuminance, chromaticity, luminous intensity, and illumination distribution of automotive exterior lighting. The Konica Minolta Chroma Meter CL-200A and Illuminance Meter T-10A enable precise measurement of the illuminance of automotive exterior lighting and can be customized with multiple receptor heads for accurate light distribution measurement.

Recommended Products:

ProMetric® I Series - Imaging Colorimeter

Chroma Meter CL-200A

Illuminance Meter T-10A

Related Links:

Evaluating Interior Ambient Lighting

Both functional and decorative lighting are essential aspects of automotive interior design. Their importance extends beyond aesthetics to encompass safety and comfort. Evaluating these lighting aspects involves evaluating their illuminance, chromaticity, and uniformity. The Konica Minolta Luminance and Color Meter CS-150 and CS-160 and the ProMetric® Imaging Colorimeter can provide precise measurements of trim lighting chromaticity and uniformity on car doors and dashboards. Additionally, the Konica Minolta Illuminance Spectrophotometer CL-500A is ideal for evaluating the illuminance, chromaticity, and uniformity of automotive interior lights.

Recommended Products:

Illuminance Spectrophotometer CL-500A

Luminance and Color Meter CS-160/CS-150

ProMetric® I Series - Imaging Colorimeter

Related Links:

Comprehensive Measurement Solutions for Automotive Industry

Konica Minolta offers leading technology and turnkey solutions for R&D and Quality Control on the automotive production line. From spectrophotometers and Total Appearance Measurement System (TAMS™) with best-in-class precision to DIN/JIS compliance light meters and state-of-art imaging photometers and colorimeters. Check out our range of testing and measurement solutions for the automotive industry now.